50 P640i Card Printer User Guide 980541-001 Rev. A

Technical Note 5 - Flip Station

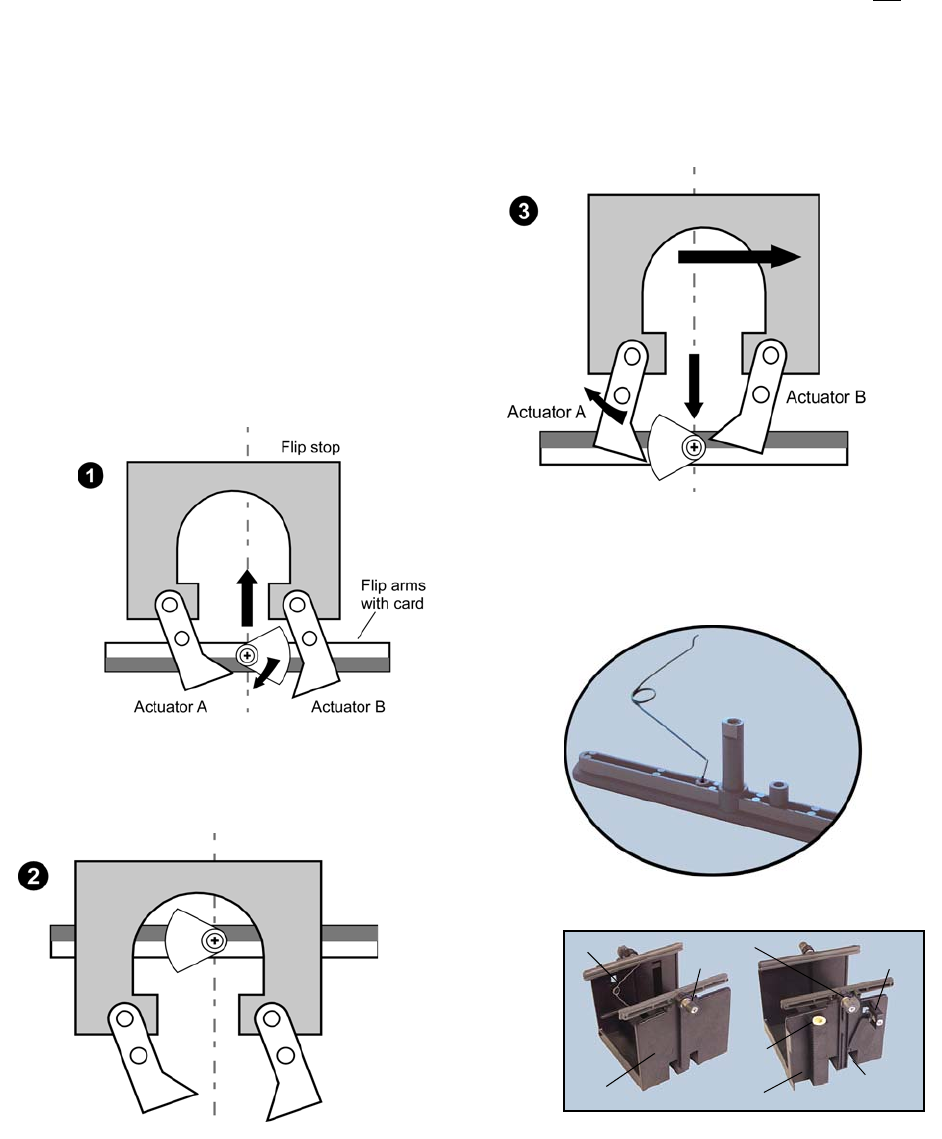

The flip station performs two independent functions:

1. It lifts the card in process clear of the carriage, flips

it upside down, then returns it to the carriage so that

its other side may be printed; 2. It lifts the fully

printed card clear of the carriage, raising it to the point

where it lines up with the laminator’s infeed path. An

ejector arm then propels the card into the laminator

infeed rollers.

Note that the flip action alternates in consecutive

cycles between clockwise and counterclockwise.

How the flip station works

As the motor driven carrier rises, taking with it the flip

arms and card, the cam is forced to rotate by the

projection on the right side of the flip stop. The

actuators do nothing at this time.

The cam

is driven

over

center by

the flip

stop, at

which

point the

flip

spring

takes

over,

fully

inverting

the card.

Shown

here at

its upper limit of travel, the carrier is about to descend.

As the carrier descends, the cam deflects Actuator A,

which in turn drives the flip stop to the right. Now,

when the next flip is called for, the cam strikes the left

projection of the flip stop, flipping the card in the

opposite direction. Actuator B, moving in parallel

with A, is then set to return the flip stop to the left

when the carrier heads downward on completion of

the flip action.

One end of the flip spring locates in a cavity in the

rear flipper arm, the other in a hole in the rear

surface of the carrier molding.

Spring

Collar

Carrier

Cam

Azimuth

adjust

Spring

locating

hole

Rack

Slide

bearing

Front Rear