980541-001 Rev. A P640i Card Printer User Guide 45

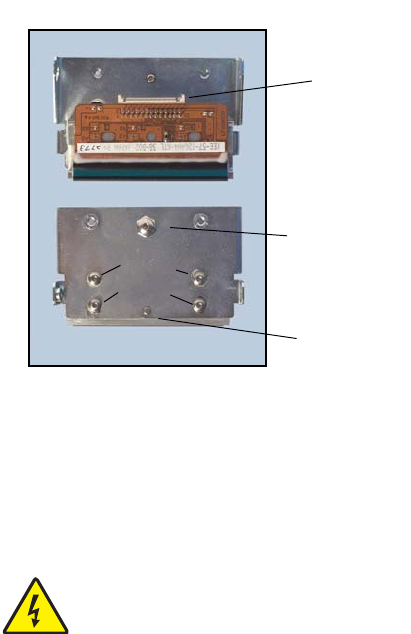

Print head attachment hardware

Print head assembly : Replacement print heads

are shipped pre-assembled to the mounting bracket

shown here. To ensure uniform contact pressure

across its width, the head is free to rotate ± 2° about its

center pivot. It is secured to the bracket by four button

head screws, tightened to allow a sliding fit.

Replacing the print head

1. Open the main cover, then power OFF.

2. Remove the color ribbon.

3. Unplug the cable from the print head.

4. Remove only the fasteners

1, 2, and 3 in the photo

on the preceding page, then lift the print head

clear.

5. Make a note of the resistance entered on the

replacement printhead’s label (should be between

2400 and 3600 Ù.

6. Connect the cable to the replacement printhead,

making sure it is seated properly, see “STOP”

above. Install the print head, securing it with

shoulder bolts

1 and 2, fully tightened, then

loosely with socket head cap screw

3 (with plain

washer) through the slot in the bracket.

7. Pivot the head assembly forward to bring the

angle adjust button head in contact with the print

head frame, then tighten screw

3.

8. Make sure the cable is not inhibiting

free rotation of

the print head about its pivot.

9. Power ON, then check print quality as follows.

10. Enter the printhead resistance in the driver

Properties “Print Station Adjustment” screen,

page TN4-4.

Print quality tests and

adjustments

The objective in the following is to find the best

compromise between image quality and ribbon

wrinkling. In the printer driver go to Printing Preferences

> Image Adjustment

, then set both Brightness and

Contrast to 50 (default condition).

1. Run

IDPrint Lite, Tech Note 8, then select

Graytone.bmp as Image 1.

2. Print two or three cards with the graytone image.

3. If you are satisfied with the overall appearance

and uniformity of the image, you might wish to

leave well alone. If you feel some improvement

could be achieved, proceed to Step 4.

4. Referring to the photo on the preceding page,

mark the head-angle-adjust button head with a

fiber tip pen to serve as a reference. Loosen screw

#3 just enough to allow sliding movement of the

printhead bracket.

5. Unlock the angle adjust button head screw, turn it

a quarter-turn counterclockwise, then re-lock it.

This will have the effect of rotating the head

counterclockwise a fraction of a degree when you

snug the button head against the printhead frame.

Tighten screw #3.

6. Print another graytone card for comparison. If

there is a noticeable improvement, try another

quarter-turn adjustment, then print again.

7. If the print quality is seen to deteriorate rather

than improve, return to the as-shipped setting of

the head angle screw, then try rotating it

clockwise in quarter-turn increments.

Electric Shock Caution • Make sure

power is disconnected before working

on the print head. Also note that the

head will likely be destroyed if power is

reapplied while you are in porcess of

reconnecting the cable, or if the plug

is not seated properly.

Connector

Head

angle

adjust

Print

head

pivot

Do NOT

tighten these