980541-001 Rev. A P640i Card Printer User Guide 41

Technical Note 3 - Magnetic

Stripe Encoder

The “mag encoder” is a factory option for the P640i.

Mag encoder installation

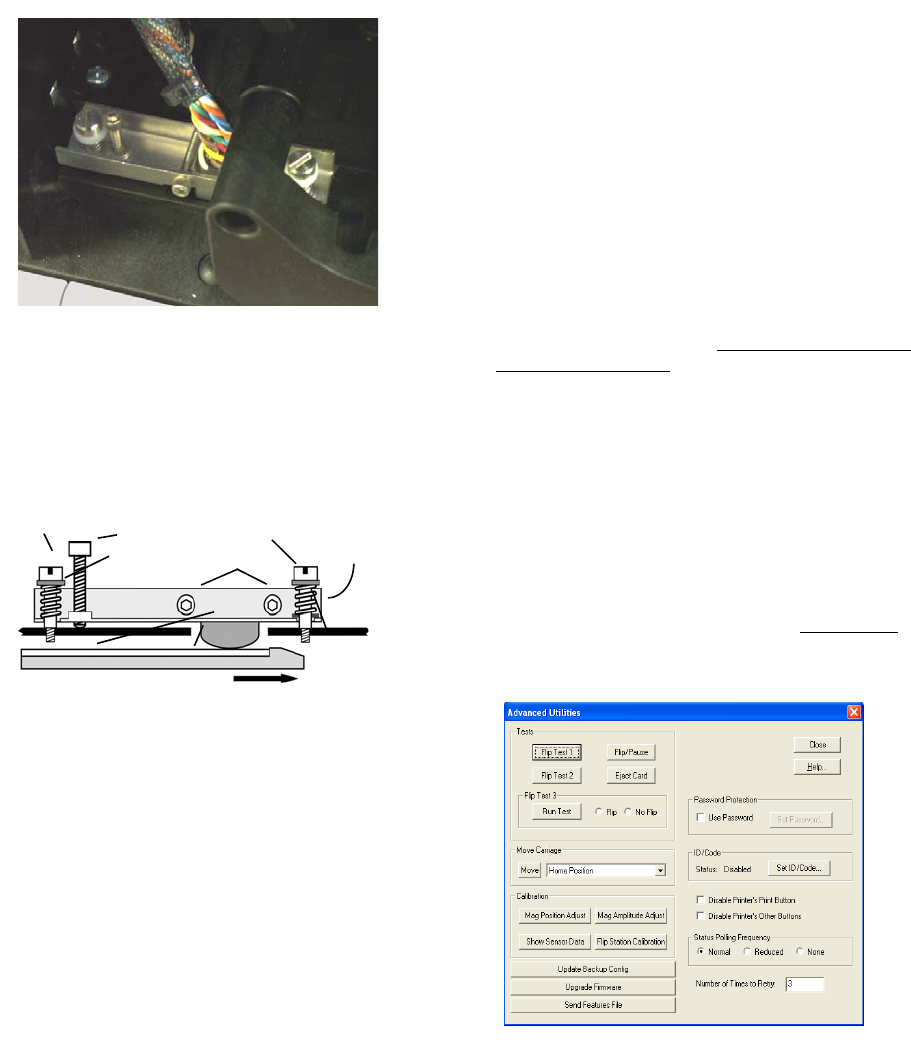

Replacement read/write heads are shipped pre-

assembled to the bracket shown here. Check the

location of the yellow wire. This must be in the lower

right corner.

Mag encoder components

Shoulder screws at the two ends of the bracket allow

vertical float. Springs hold the read/write head firmly

in contact with the card’s mag stripe.

Cleaning the read/write head

The head needs to be cleaned only if encoding

becomes troublesome. (This will show up as extra

passes of the card under the head if the Mag Verify

function is enabled - recommended - in Printing

Preferences.) To clean the head, turn power OFF and

remove all cards from the hopper. Drive the truck to

the right, clear of the mag encoding station, by

rotating the card transport knob left of the laminator.

Reaching down through the floor of the hopper, clean

the head with a Q-Tip dipped in isopropyl alcohol.

Allow several minutes drying time before running the

printer.

Replacing the read/write head

As shipped, the replacement read/write head is a

complete assembly comprising mounting bracket and

clamp hardware. Other screws and springs are not

included.

Remove, setting aside for re-use, the shoulder screws

and adjustment screw from the defective assembly,

together with springs and washers. Install the

adjustment screw in the replacement bracket, bringing

its tip flush with the bottom surface of the bracket.

Check how the head sits in the bracket. Look for

symmetry, with the upper rim of the head

(surrounding the “potted” wires),

almost even with the

bracket, just a hair below. Install the encoder

assembly, taking care that the shoulder screws do not

clamp either end of the bracket or the washer at the

right hand end. Check that the assembly is

free to move

up and down

at both ends.

Adjust the mag encoder using Mag Amplitude Adjust

and Mag Position Adjust utilities in the Windows

printer driver, see below.

Magnetic Encoding Functions in

the Driver

Mag Position and Amplitude

For this procedure you will need to cut a feeler gauge

about ¼" wide (6 mm) from a standard CR-80 card

(which should be 0.03”/0.75 mm thick).

Start > Printers (or Printers and Faxes) > Right click

Zebra P640i > Properties > Device Settings > Control

> Advanced Utilities > Calibration

1. If you have not already done so (see Replacing

the read/ write head, above) back off the adjust-

ment screw (counterclockwise) until the head

bracket is fully down.

Shoulder

screw

Adjustomg

screw (3/32"

Spring

Clamp

Screws

Nylon

Washer

Steel

Washer

Spring

CardRead/Write

head