52 P640i Card Printer User Guide 980541-001 Rev. A

If you detect that either of the arms catches at one end

of the platen, but is free at the other, the carrier needs

Azimuth adjustment, see below. Always correct for

azimuth error before adjusting the gap between arms

and platen.

If there is no azimuth error, but insufficient clearance

between arms and platen, see

Gap adjustment below.

Azimuth adjustment: The flip station carrier is

held in alignment with the platen by a U-shape

molding that rides along a fixed rail in the motor

housing behind the carrier. Using a fiber tip pen mark

the screw for reference, then adjust it in very small

increments, such as 1/8 of a turn. A full turn of the

screw moves the U-shape molding about 0.08" (2

mm), rotating the carrier almost 3º.

To fine tune the azimuth adjustment, run Flip Test 3

with flip

selected. If the gap between the rear flipper

arm and the platen is to spec (0.004") at the arm’s

mid-point, and if neither end of the arm snags after

repeated flip cycles, you can be sure the azimuth

adjustment is good.

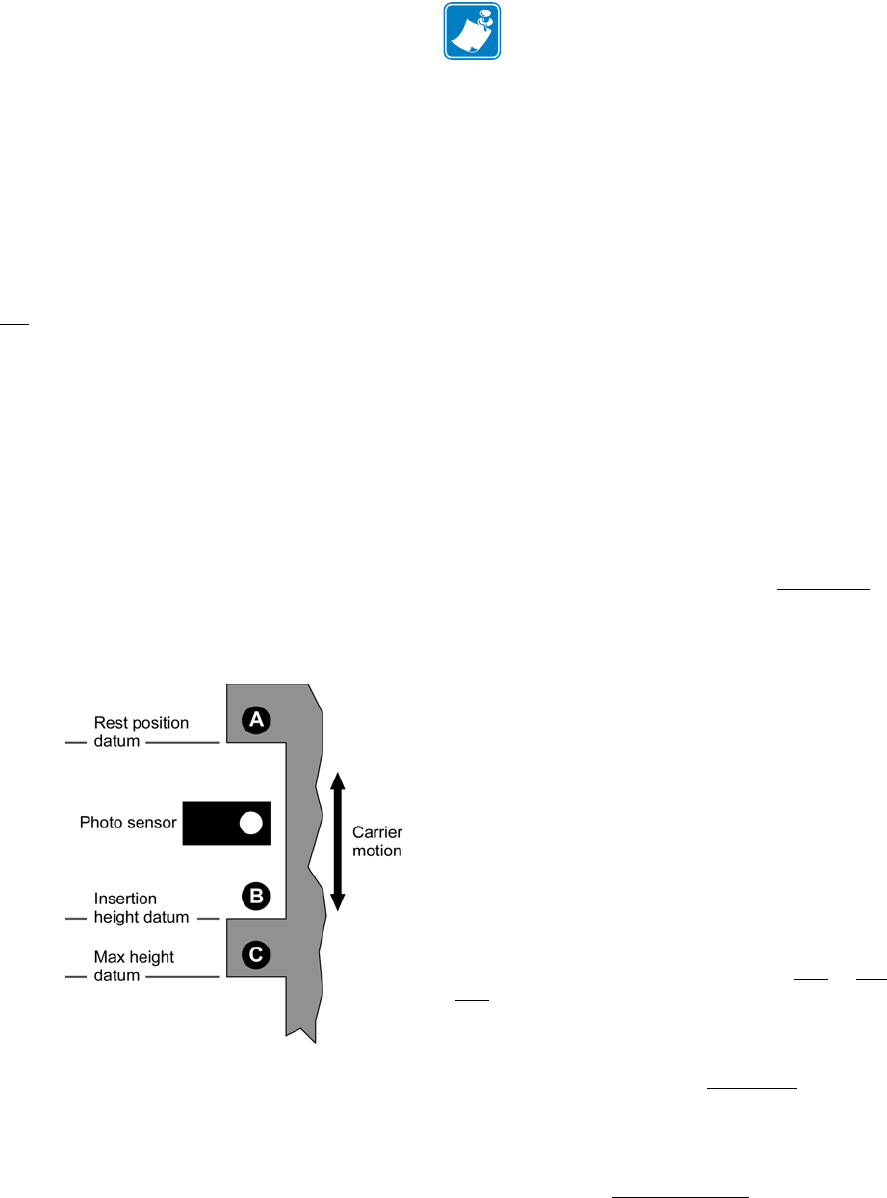

Flip carrier sensor tabs: This view is from left to

right, along the center wall of the printer ockwise

rotation of the azimuth adjust screw causes clockwise

rotation of the carrier assembly, viewed from above.

Example: if the platen tugs down the right hand end of

front flipper arm as the carrier elevates, the carrier

needs clockwise rotation.

Gap adjustment: The flipper arms must be

separated so that they clear the platen, but not so far

that they

lose their

grip on

the card.

There is

a fine

line

between

too tight

(grabbin

g the

platen)

and too

loose

(failing

to hold

the card

securely)

.

Because it is easily accessible, and doesn’t require

removal of the rear cover, try to correct the problem

with the front flipper adjustment.

Mark the bushing for reference with a fiber tip pen.

Using a ¼" open end wrench, adjust in

very small

increments

, such as 1/8 of a turn. A full clockwise turn

of the screw moves the bushing in by about 0.03” (¾

mm).

If you are starting from scratch, set the nose of

bushing about 0.02" (½ mm) proud of the inner

surface of the carrier. You can estimate this by

comparison with a CR-80 card, which is 0.03" thick.

After adjusting the gap: Check operation of the

flip station by running

Flip Test 3 with Flip, both with

and without a card in the flipper arms.

The rear flipper arm is different: You need to

remove the rear cover for access. Also, it’s not

possible to adjust the bushing without first removing

the cam.

Flip Station Routines in the Driver

Start > Printers (or Printers and Faxes) > Right click

Zebra P640i > Properties > Device Settings > Control

> Advanced Utilites

Flip Test 1: Picks up a card, runs it to the flip

station, flips it, raises it to the laminator infeed, then

ejects it through the laminator. The sequence repeats

until the PRINT button is pressed and released.

Flip Test 2: Picks up a card, runs it to the flip

station, flips it, returns it to the platen, then backs it

out to the card sensor (by the mag head). The

sequence repeats until the PRINT button is pressed

and released.

Flip Test 3: See Flip Station Adjustment

Procedure, preceding page. Exercises the flip station

by raising and lowering the flip station carrier, one

cycle per click. The radio buttons select Flip

or No

Flip cycles.

Eject Card: Picks up a card, runs it to the flip

station, raises it to the laminator infeed, then ejects

it through the laminator. Like Flip Test 1

, but done

once only, and without flipping.

Flip/Pause: Picks up a card, runs it to the flip

station, raises it to the laminator infeed, then holds this

position (termed the Insertion Height

in the flip

station dialog) until the user presses the PRINT button

(at which point the flip carrier descends, and the truck

returns the card to the hopper).

Note • Inserting a CR-80 card into the

flipper arms to check for grip is easier if

you remove the color ribbon.