10-3

Daily Inspection and Periodic Inspection (1/3)

Inspection cycle

Inspection

location

Inspection item Inspection content Inspection method Criteria

Standard

replacement

period

Instruments

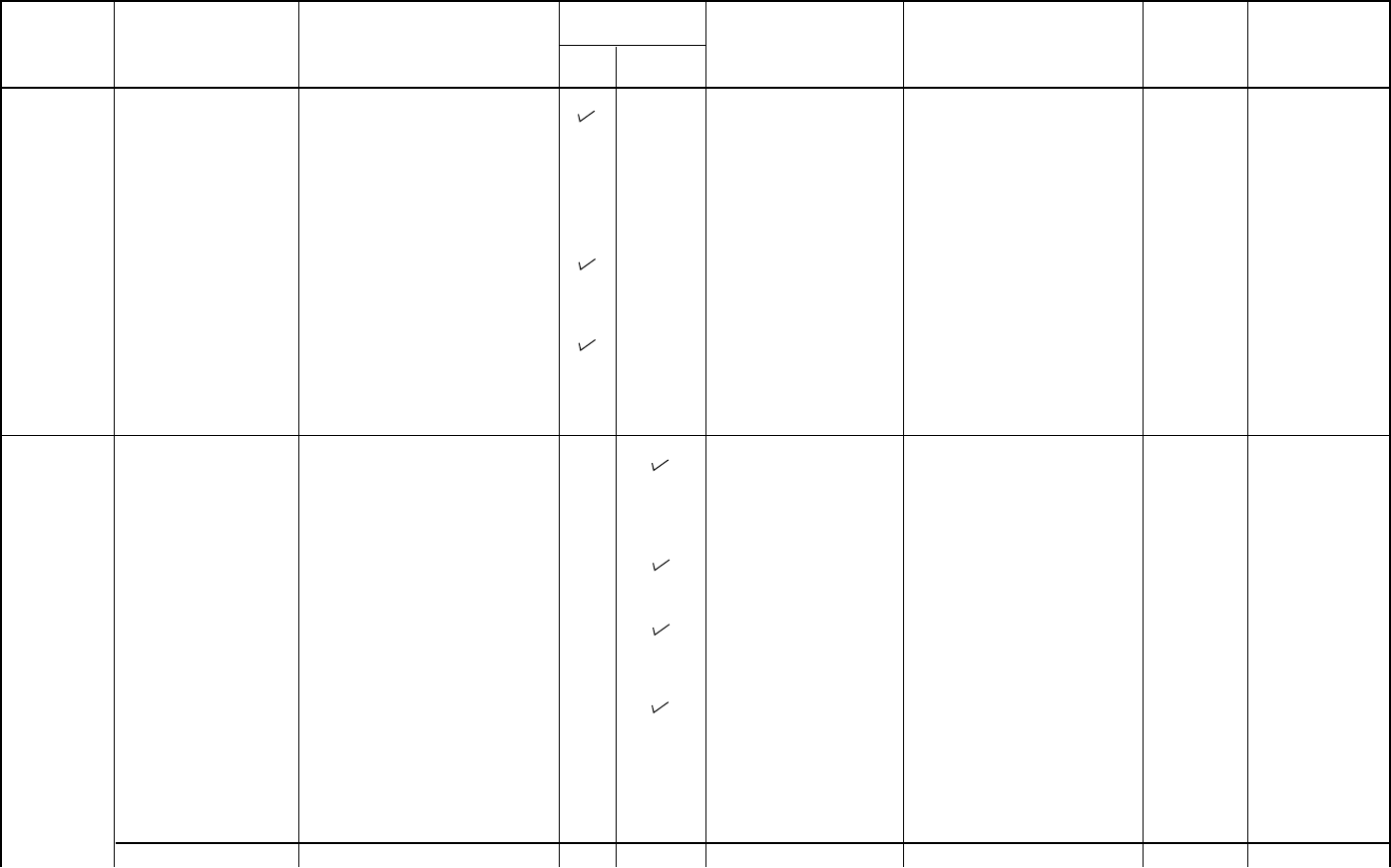

Daily

Periodic

Overall Ambient

environment

Check ambient temperature,

humidity, dust, corrosive

gases, oil mist, etc.

Ambient temperature

between -10 to +50˚C;

no icing.

Thermometer

__

Devices overall Check for abnormal

vibrations and noise.

Visual and aural

inspection.

Ambient humidity 20 to

90%; no dew condensation.

Hygrometer

Power supply

voltage

Check the input line voltage. Measure the voltage

between inverter

terminals R(L1),

S(L2) and T(L3).

No abnormalities.

200 to 220 V, 50 Hz

200 to 230 V, 60 Hz

380 to 415 V, 50 Hz

400 to 460 V, 60 Hz

Tester

Main

circuit

Overall

(1) Insulation resistance test

(between main circuit

terminals and grounding

terminal)

(2) Check installation for

looseness.

(3) Check for evidence of

overheating in the various

components.

(4) Clean.

No abnormalities in (1) and

(2).

Tightening torque (kgf.cm)

• M3: 8 - 10

• M4: 12 - 15

• M5: 20 - 25

• M6: 25 - 30

• M8: 100 - 135

• M10: 150 - 200

Tightening torque for IPM

and Diode modules

(kgf.cm)

• M4: 10-15

• M5: 15-20

• M6: 20-25

__

500 V class

Megohm meter

(2) Tighten.

(3) Visual

inspection.

(1) Increase tighting

Making a check

on the terque is

needed for the

increase tighten-

ing of the modules

such as a power

module, diode

module. Do not

execute increse

tightening with

no torque gauge

prepared.