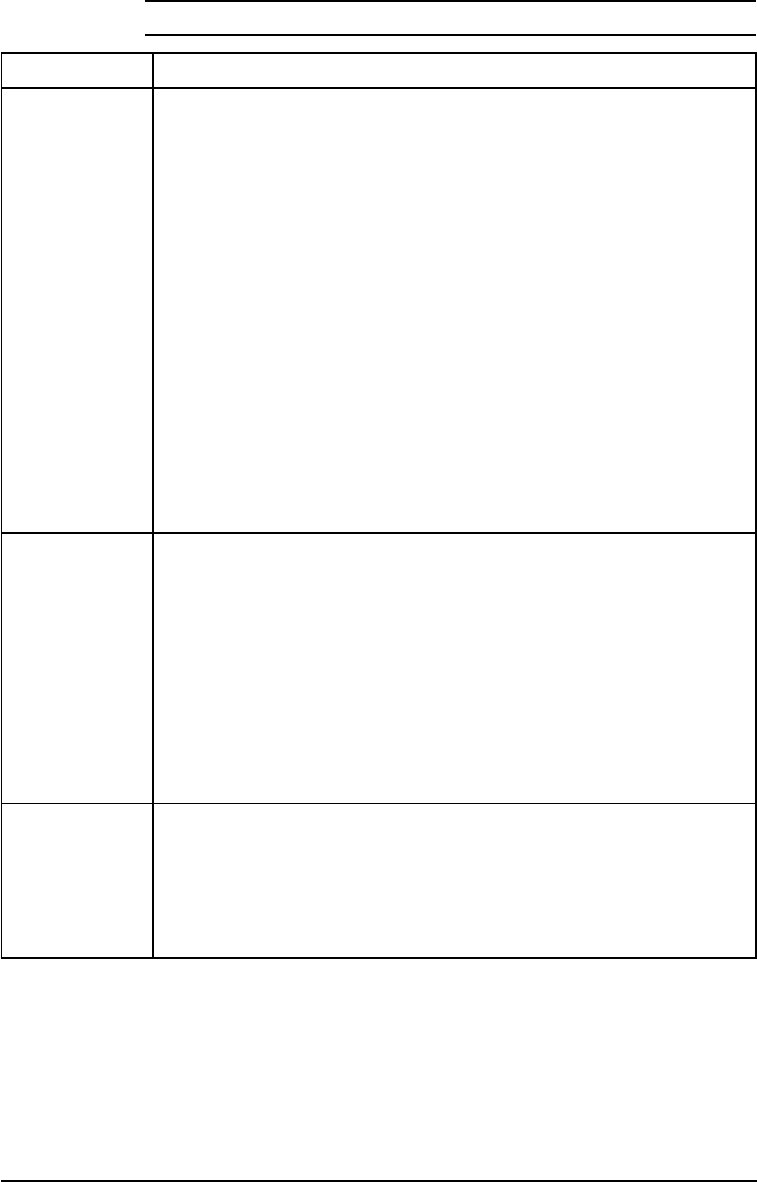

Table 5-2 Media Use Guidelines

Media Type Guidelines

Paper and

Preprinted Forms

• For best results, use conventional 20-lb (75 g/m

2

) xerographic paper. Make sure the paper is

of good quality and free of cuts, nicks, tears, spots, loose particles, dust, wrinkles, voids, and

curled or bent edges.

• Do not use paper with cutouts or perforations (including standard pre-punched paper)

with

holes 8 mm in diameter or larger.

• Do not use letterhead papers that are printed with low-temperature inks, such as those used in

some types of thermography.

• Use only colored papers or preprinted forms that use inks compatible with your printer’s fusing

temperature (392°F/200°C for 0.1 second).

• Keep paper stored in moisture-proof wrapping to prevent changes in moisture content that

may cause poor print quality, jamming, or curling.

• Avoid paper with ragged or cut edges to prevent feeding problems.

• Do not use paper heavier than 28-lb (105 g/m

2

) from trays other than Tray 1. Tray 1 can feed

16-lb Bond to 110-lb Index (60 - 199 g/m

2

) paper. Heavier paper may cause misfeeds,

stacking problems, paper jams, poor toner fusing, poor print quality, and excessive mechanical

wear.

• Do not use paper that is very rough, very smooth, or embossed. Such paper may cause

feeding or print quality problems, and rough papers may have poor toner adhesion.

Adhesive Labels

• Use only labels recommended for use in laser printers.

• Use only the Left Output Bin for printing labels.

• The adhesive material should be stable at the 392° F/200° C temperatures encountered in the

fusing process. None of the adhesive between the labels should be exposed.

• Use labels with no exposed areas between labels. Using label stock with spaces between

labels often causes labels to peel off during the printing cycle, causing serious jamming

problems. Use a sheet of labels only once.

• Labels must lie flat with no more than 0.5 in (13 mm) of curl in any direction.

• Do not use labels that have separated from the backing sheet or with wrinkles, bubbles, or

other indications of delamination.

Overhead

Transparencies

• Overhead transparencies used in HP LaserJet printers must be able to withstand the

392°F/200°C temperature encountered in the fusing process.

• Use only transparencies recommended for use in laser printers. Because transparency films

tend to stick to each other, remove each transparency from the output bin before printing the

next one.

• Use only the Left or Top Output Bins for printing transparencies.

5-6 Print Tasks EN