Chapter 4 Explanation of Functions

(2) Overload nitice function

The overload notice function allows you to make the inverter output an overload notice signal before

tripping because of overload.

You can use this function effectively to prevent the machine (e.g., a conveyor)driven by the inverter from

being overloaded and prevent the conveyor from being stopped by the overload protection of the inverter.

To use this function, assign function "03" (OK) or "26" (OL2) to one of the intelligent output terminals [11] to

[15] (C021 to C025) and the alarm relay terminal (C026). (Two types of overload notice signal are available

for output.)

Item Function code Data or range of data Description

00

Enabling the warning output during

acceleration, deceleration, and constant

Overload signal output

mode

C040

01 Enabling the warning output during constant

0.0 Disabling the warning output

Overload level setting C041

0.1 to "2.0 x rated

current" (A)

Specifying the current at which to output the

OL signal (overload notice advance signal

(1))

0.0 Disabling the warning output

Overload setting (2) C111

0.1 to "2.0 x rated

current" (A)

Specifying the current at which to output the

OL2 signal (overload notice advance signal

(2))

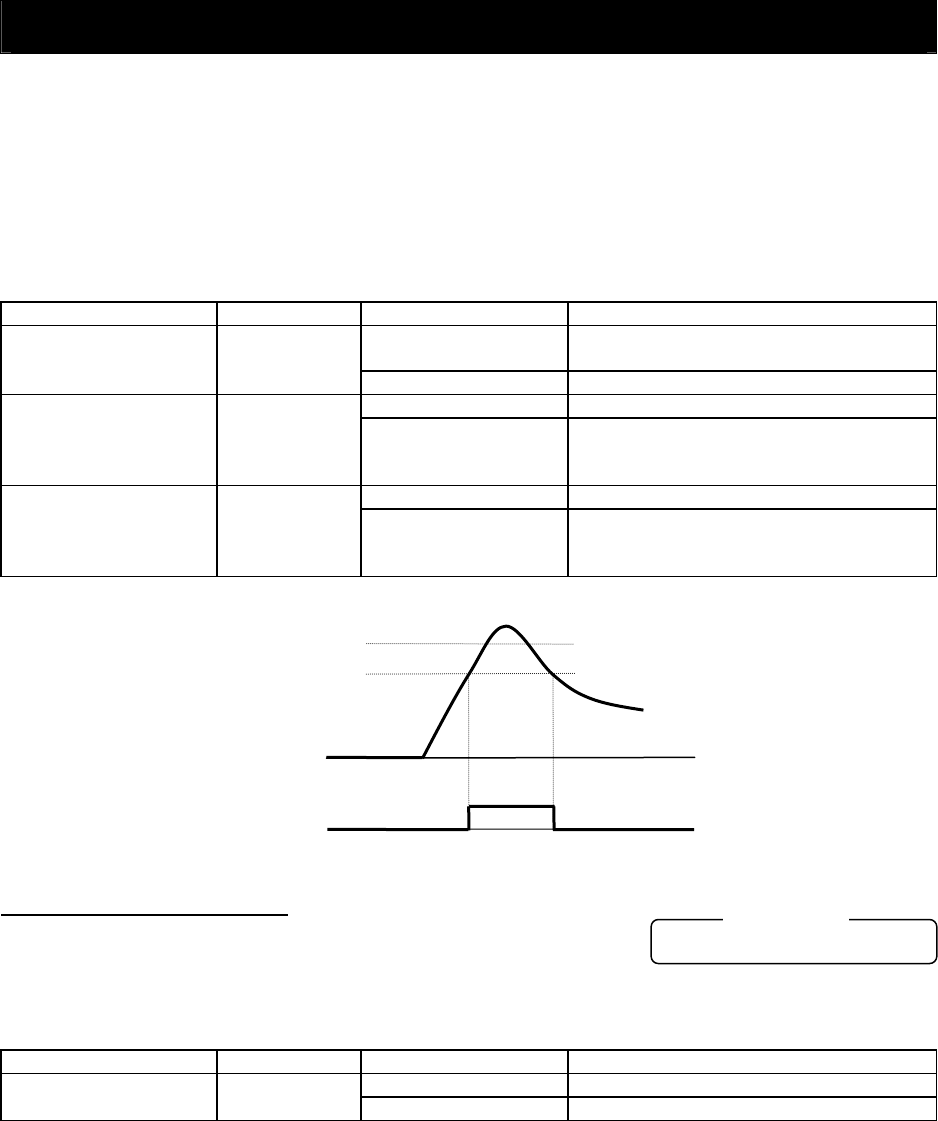

Overload restriction

setting b022/b025

Overload level setting

C041/C111

Output current

OL/OL2 output

4.2.31 Overcurrent restraint

b027: Overcurrent suppression enable

Related code

The overcurrent restraint function allows you to restrain the

overcurrent that can occur when the output current sharply increases

because of rapid acceleration.

You can enable or disable the function by setting the overcurrent suppression enable (b027).

Item Function code Data or range of data Description

00 Disabling the overcurrent restraint Overcurrent

suppression enable

b027

01 Enabling the overcurrent restraint

Note: When using the inverter for a lift, disable the overcurrent restraint function. If the overcurrent

restraint functions during the lift operation, the lift may slide down because of insufficient torque.

4 - 40