Chapter 2 Installation and Wiring

2 - 11

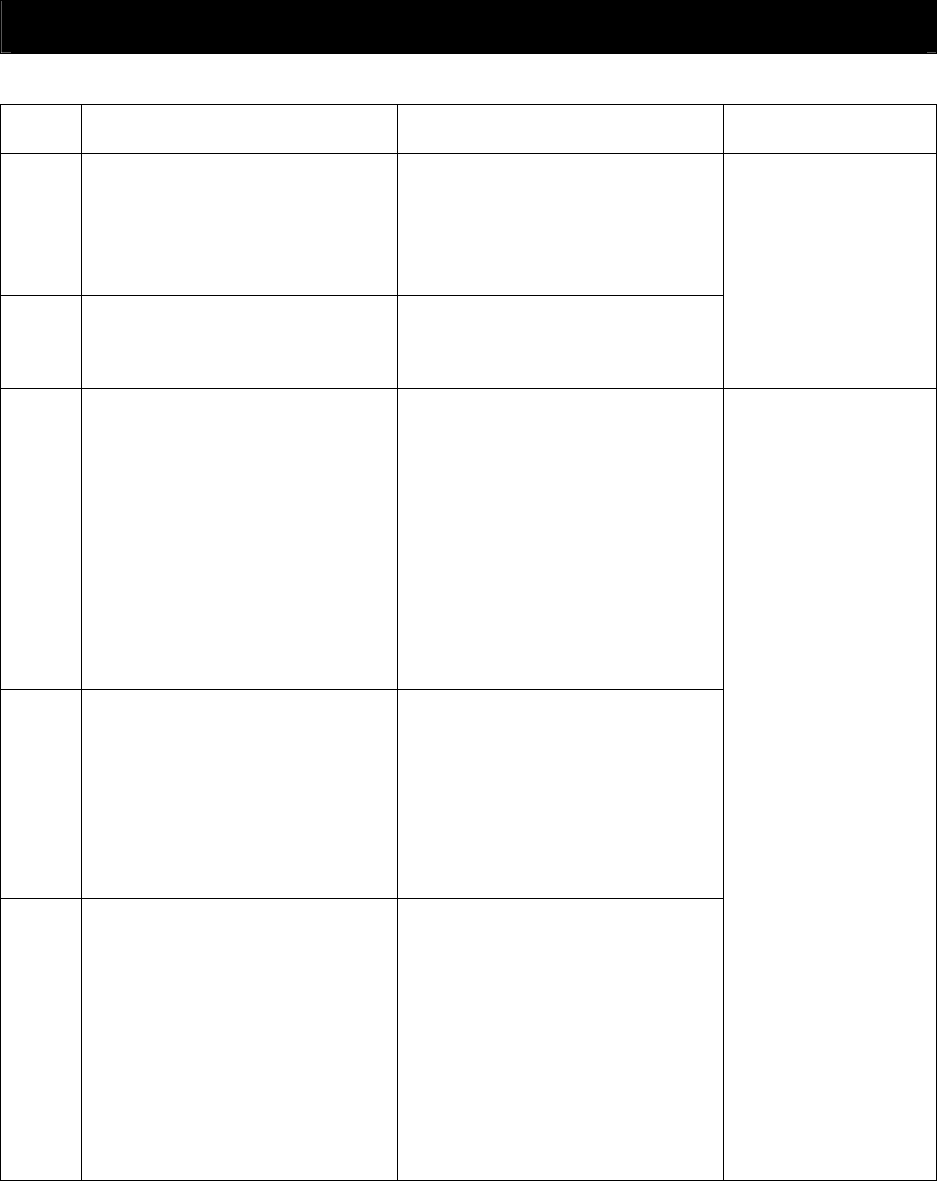

Safety categories defined by EN954-1 (JIS B 9705)

Category Safety requirement System behavior

Principle for achieving

safety

B

Components, safety-related parts of

control system, and protective equipment

must be designed, manufactured,

selected, assembled, and combined in

accordance with related standards to

ensure resistance to the anticipated

adverse effects of faults.

A defect (fault) may cause a loss of the

safety function.

1

The requirements of category B must be

applied.

Proven components and safety principles

must be applied.

A defect (fault) may cause a loss of the

safety function. However, the probability of

loss is less than that specified for category

B.

Characterized mainly by

the selection of

components

2

The requirements of category B and

proven safety principle specifications

must be applied. The safety function must

be checked by the machine control

system at appropriate intervals. The

requirements of category B and proven

safety principle specifications must be

applied. Safety-related parts must be

designed to meet the following

requirements:

- Any single defect (fault) in a part must

not cause any loss of the safety functions.

- If a single defect (fault) occurs, it must

always be detected when the safety

function can be reasonably implemented.

- A defect (fault) occurring during checking

may cause a loss of the safety function.

- A loss of the safety function is detected by

checking.

3

The requirements of category B and

proven safety principle specifications

must be applied. Safety-related parts

must be designed to meet the following

requirements:

- The safety function always operates

when a single defect (fault) occurs.

- Each single defect (fault) is eventually

detected to prevent the loss of the

safety function.

- The safety function always operates when

a single defect (fault) occurs.

- Almost all defects (faults) are detected.

- Accumulation of undetected defects

(faults) may cause a loss of the safety

function.

4

The requirements of category B and

proven safety principle specifications

must be applied. Safety-related parts

must be designed to meet the following

requirements:

- Any single defect (fault) in a part must

not cause any loss of the safety function.

- If a single defect (fault) occurs, it must

be detected when or before the next

operation request is made to the safety

function. If single defects (faults) cannot

be detected, the accumulation of

defects (faults) must not cause any loss

of the safety function.

- The safety function always operates when

a single defect (fault) occurs.

- Each single defect (fault) is eventually

detected to prevent the loss of the safety

function.

Characterized mainly by

the structure

Note: The system manufacturer is responsible for selecting the level of risk factors in accordance with EN954-1.

[Stop categories defined by EN60204-1]

The examples of wiring shown below are based on the three stop categories compliant with European Machinery

Directive EN60204-1.

- Category 0: (Uncontrolled) stopping by immediate removal of power to machine actuators

- Category 1: Stopping by removal of power after controlled stopping with power to machine actuators retained

- Category 2: Controlled stopping with power to machine actuators retained

Note: The Safe Stop function must be activated at least once a year for preventive maintenance purposes.

Note: Before preventive maintenance, the machine must be turned off. If the power supply to the motor is not turned

off during testing, the Safe Stop function will not operate. In such case, the inverter must be replaced.