Chapter 4 Explanation of Functions

4.2.102 Torque LAD stop function

A044/A244: V/F characteristic curve selection,

1st/2nd motors

b040: Torque limit selection

b041 to b044: Torque limits (1) to (4)

b045: Torque limit LADSTOP enable

Related code

The torque LAD stop function is effective when "03" (sensorless

vector control), "04" (0Hz-range sensorless vector control), or

"05" (vector control with sensor) is specified for the V/F

characteristic curve selection (A044/A244). This function

temporarily stops the frequency-based deceleration function

(LAD) when the torque limitation function operates.

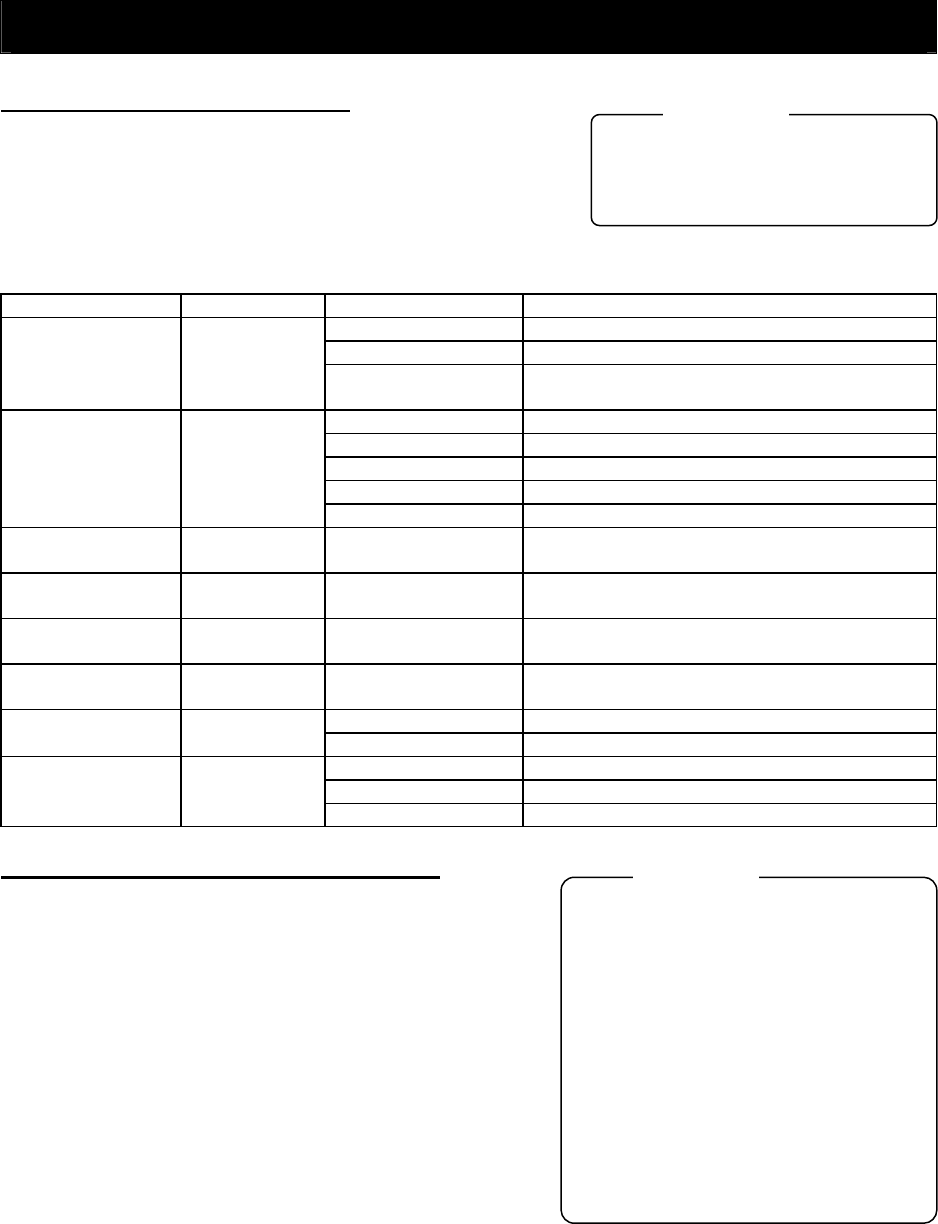

Item Function code Data or range of data Description

03 Sensorless vector control

04 0Hz-range sensorless vector control

V/F characteristic

curve selection

A044/A244

05

Vector control with sensor (not available for

A244)

00 Quadrant-specific setting mode

01 Terminal-switching mode

02 Analog input mode

03 Option 1 mode

Torque limit

selection

b040

04 Option 2 mode

Torque limit (1) b041 0 to 200 (%)

Forward powering (in quadrant-specific setting

mode)

Torque limit (2) b042 0 to 200 (%)

Reverse regeneration (in quadrant-specific

setting mode)

Torque limit (3) b043 0 to 200 (%)

Reverse powering (in quadrant-specific setting

mode)

Torque limit (4) b044 0 to 200 (%)

Forward regeneration (in quadrant-specific

setting mode)

00 Disabling the torque LAD stop function Torque limit

LADSTOP enable

b045

01 Enabling the torque LAD stop function

40 Whether to enable torque limitation

41 Torque limit switch 1

Terminal function C001 to C008

42 Torque limit switch 2

4.2.103 High-torque multi-motor operation

The high-torque multi-motor operation function allows you to

make a single inverter operate the two motors (having the

same specifications) that drive a single load (machine). This

function is effective when the V/F characteristic curve selection

is the sensorless vector control or 0Hz-range sensorless

control.

To use the function, adjust the inverter settings required for the

sensorless vector control (see Section 4.2.92) or 0Hz-range

sensorless control (see Section 4.2.93), except for the motor

constant settings. Adjust the motor constants as follows:

A044/A244: V/F characteristic curve selection,

1st/2nd motors

F001: Output frequency setting

b040: Torque limit selection

b041 to b044: Torque limits (1) to (4)

H002/H202: Motor data selection, 1st/2nd motors

H003/H203: Motor capacity, 1st/2nd motors

H004/H204: Motor poles setting, 1st/2nd motors

H005/H205: Motor speed constant, 1st/2nd motors

H020/H220: Motor constant R1, 1st/2nd motors

H021/H221: Motor constant R2, 1st/2nd motors

H022/H222: Motor constant L, 1st/2nd motors

H023/H223: Motor constant Io, 1st/2nd motors

H024/H224: Motor constant J, 1st/2nd motors

H050/H250: PI proportional gain, 1st/2nd motors

H051/H251: PI integral gain, 1st/2nd motors

H052/H252: P proportional gain setting, 1st/2nd

motors

Related code

1) For constants R1, R2, and L, specify a value half as large

as that normally specified for one motor.

2) For constant Io, specify a value twice as large as that

normally specified for one motor.

3) For constant J, specify a value half as large as the total

moment of inertia of the two motors and the load connected

to them.

Select the motor capacity that is closest to the collective capacity of both motors.

If different loads are driven by the two motors operated by the inverter, the load fluctuations on one motor

may change the other motor's operation status, and the inverter may be unable to normally control the

motors. Be sure to configure your system so that the motors drive only a single load or multiple loads that

can, at least, be recognized as a single load.

4 - 95