Chapter 4 Explanation of Functions

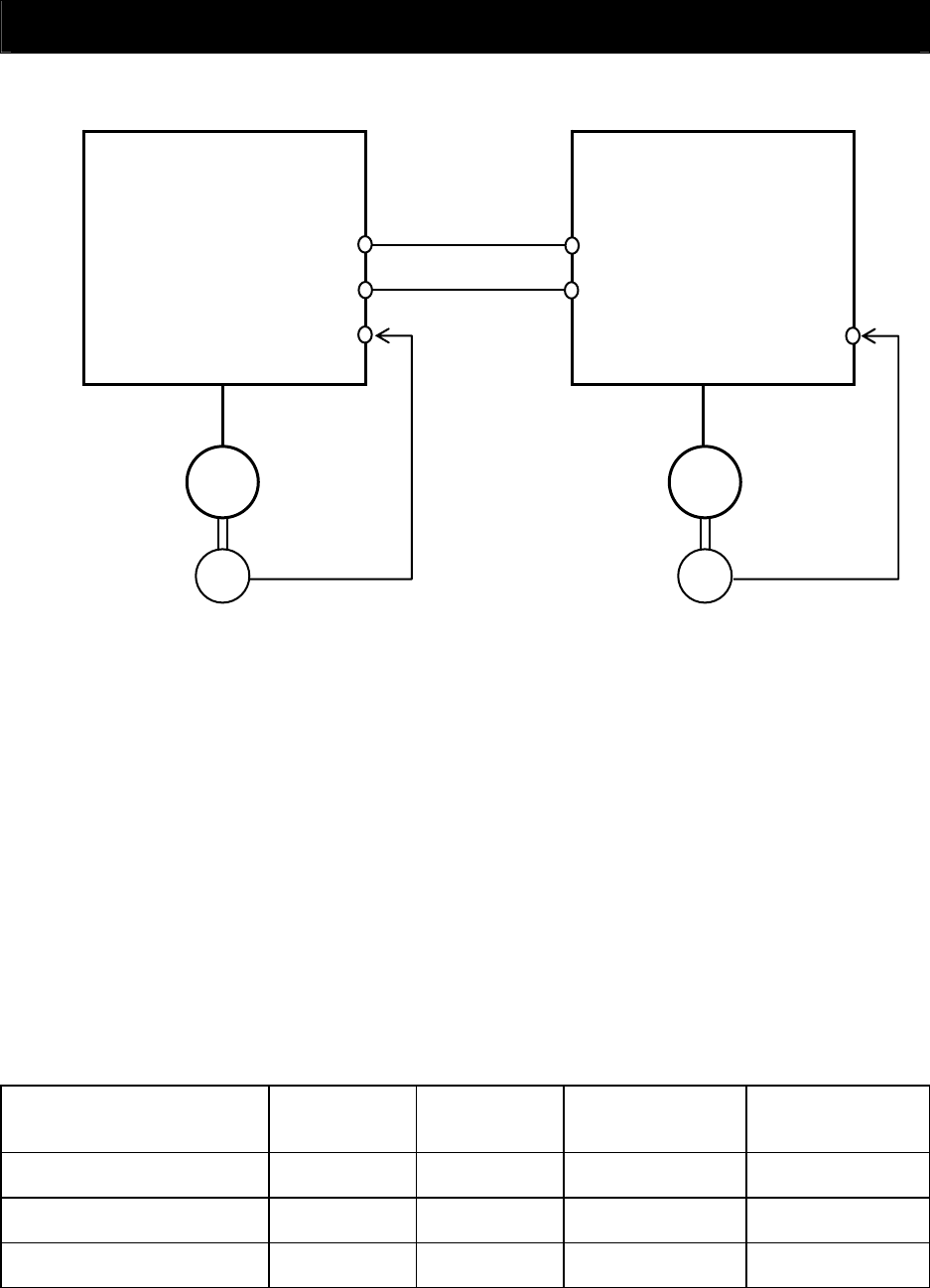

<Example of use: Synchronous operation>

Master inverter Slave inverter

EAP,EBP

EAN,EBN

SAP,SBP

SAN,SBN

EG5

EAP,EBP

EAN,EBN

EC

M

EC

M

AP,BP

AN,BN

EG5

Sub-motor

Main motor

On the inverter (master inverter) for the main motor, specify either the speed control or pulse train position

control mode.

On the inverter (slave inverter) for the sub-motor, specify the pulse train position control mode.

<Example of settings>

- Main motor: Encoder pulse-per-revolution (PPR) setting = 1024 (pulses)

- Sub-motor: Encoder pulse-per-revolution (PPR) setting = 3000 (pulses)

- Ratio of main motor speed to sub-motor speed: 2:1

To operate the motors under the above conditions, adjust the parameters on the slave inverter as follows:

Pulse train mode setting (P013): 00 (90º-phase-shift pulse train)

Electronic gear set position selection (P019): 01 (REF)

Electronic gear ratio numerator setting (P020): 3000

Electronic gear ratio denominator setting (P021): 1024 x 2 = 2048

The table below lists the examples of the ratio of main motor speed to sub-motor speed according to the

settings of "P019" to "P021" (on the assumption that the encoder pulse-per-revolution (PPR) setting of

"1024" should be set on both inverters).

Electronic gear set position

selection (P019)

REF

(Position

command side)

REF

(Position

command side)

FB

(Position feedback

side)

FB

(Position feedback

side)

Electronic gear ratio numerator

setting (P020)

1024 2048 1024 2048

Electronic gear ratio

denominator setting (P021)

2048 1024 2048 1024

Sub-motor speed/main motor

speed

1/2 2 2 1/2

4 - 104