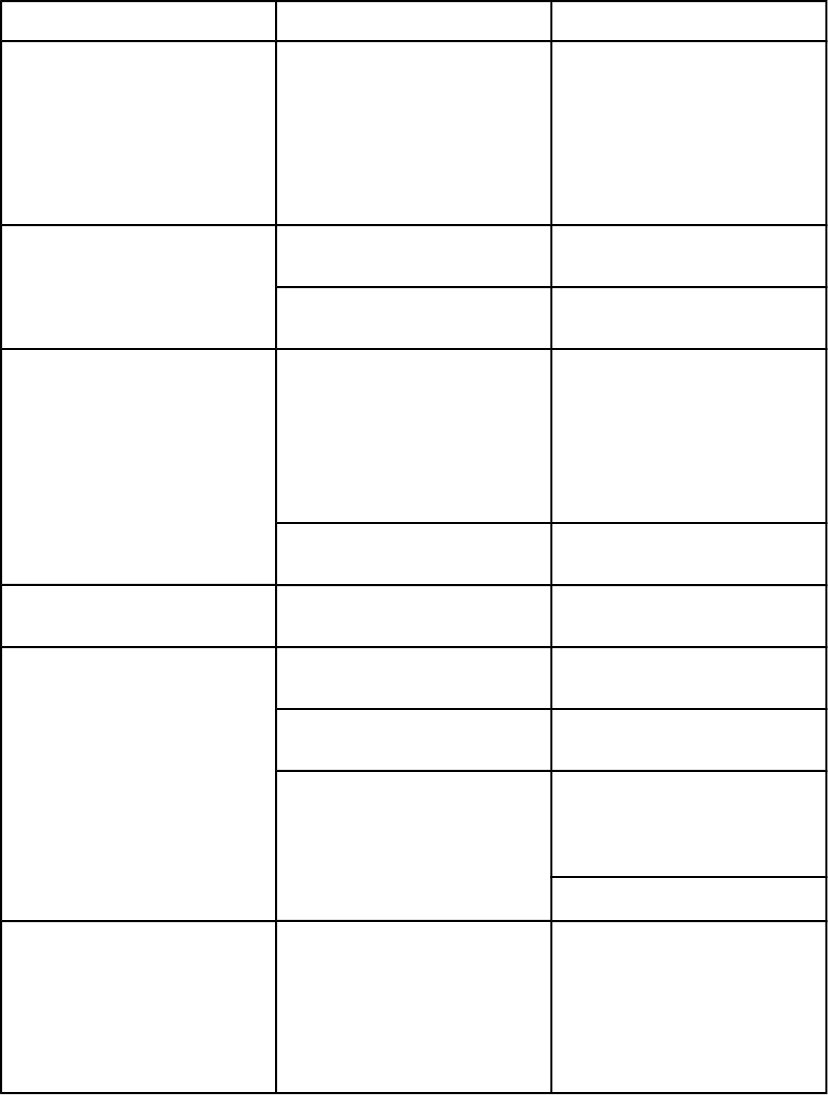

Solving print-media problems

The following problems with paper cause print quality deviations, jamming, or even damage

to the device.

Problem Cause Solution

Poor print quality or toner

adhesion

The paper is too moist, too

rough, too heavy or too

smooth, or it is embossed or

from a faulty paper lot.

Verify that the appropriate

media type was selected in the

printer driver.

Try another kind of paper,

between 100 and 250

Sheffield, 4% to 6% moisture

content.

Dropouts, jamming, or curl The paper has been stored

incorrectly.

Store paper flat in its moisture-

proof wrapping.

The paper has variability from

one side to the other.

Turn the paper over.

Excessive curl The paper is too moist, has the

wrong grain direction, or is of

short-grain construction.

Verify that the appropriate

media type was selected in the

printer driver.

Try printing on media from a

new or different package.

Use long-grain paper.

The paper varies from side-to-

side.

Turn the paper over.

Jamming, damage to device The paper has cutouts or

perforations.

Use paper that is free of

cutouts or perforations.

Problems with feeding The paper has ragged edges. Use high-quality paper that is

made for color laser printers.

The paper varies from side-to-

side.

Turn the paper over.

The paper is too moist, too

rough, too heavy or too

smooth, has the wrong grain

direction, or is of short-grain

construction or it is embossed

or from a faulty paper lot.

Try another kind of paper,

between 100 and 250

Sheffield, 4 to 6% moisture

content.

Use long-grain paper.

Print is skewed (crooked)

The media guides might be

incorrectly adjusted.

Remove all media from the

input tray, straighten the stack,

and then load the media in the

input tray again. Adjust the

media guides to the width and

length of the media that you

are using and try printing again.

ENWW Print problems 117