Installing, Connecting and Using the Encoder Mod-

72 AX2550 Motor Controller User’s Manual Version 1.9b. June 1, 2007

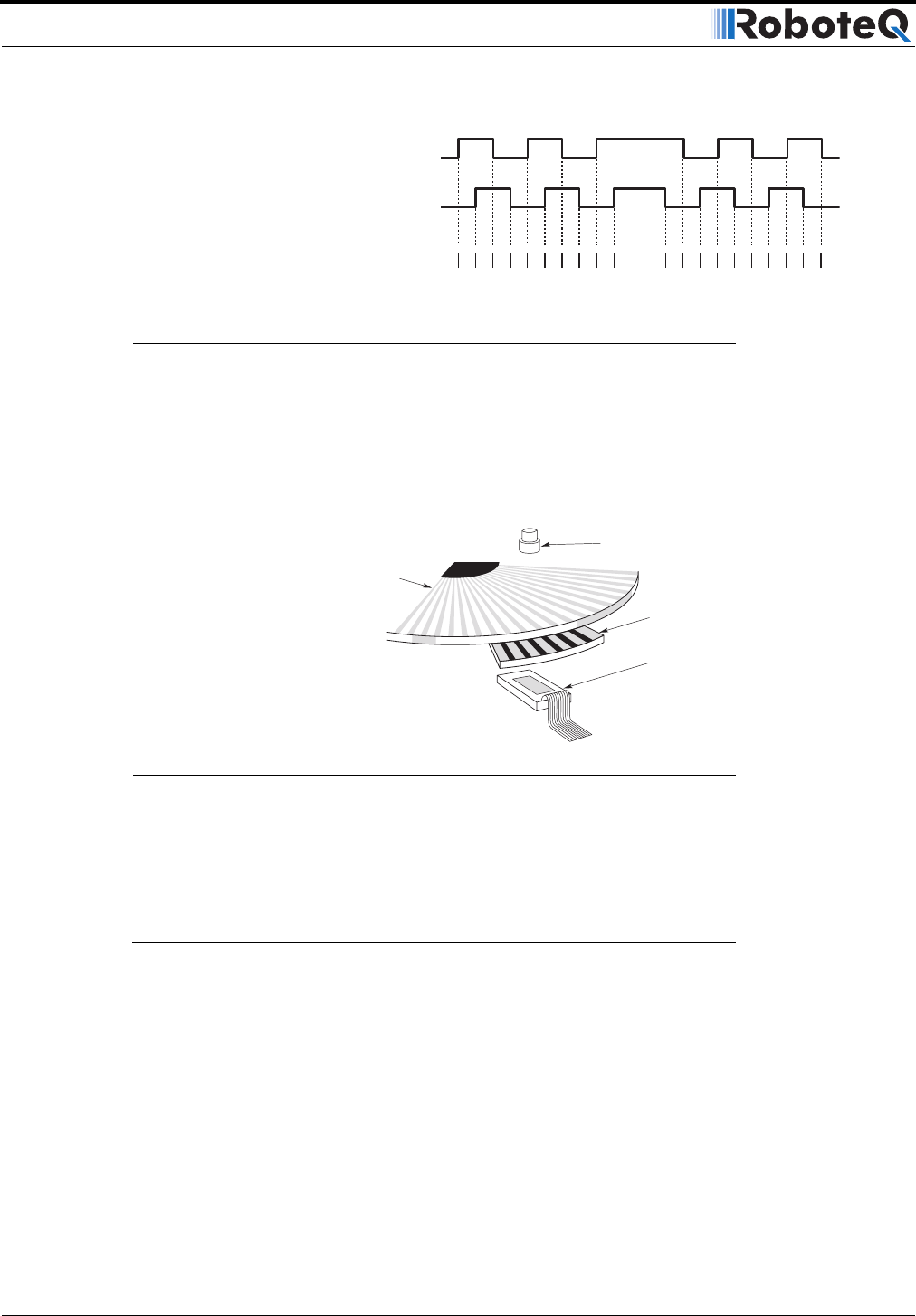

The figure below shows the typical construction of a quadrature encoder. As the disk

rotates in front of the stationary mask, it shutters light from the LED. The light that passes

through the mask is received by the photo detectors. Two photo detectors are placed side

by side at so that the light making it through the mask hits one detector after the other to

produces the 90o phased pulses.

Unlike absolute encoders, incremental encoders have no retention of absolute position

upon power loss. When used in positioning applications, the controller must move the

motor until a limit switch is reached. This position is then used as the zero reference for all

subsequent moves.

Recommended Encoder Types

The module may be used with most incremental encoder module as long as they include

the following features:

• Two quadrature outputs (Ch A, Ch B), single ended signal

• 2.5V minimum swing between 0 Level and 1 Level on quadrature output

• 5VDC operation. 100mA or less current consumption per encoder

More sophisticated incremental encoders with differential outputs, index, and other fea-

tures may be used, however these additional capabilities will be ignored.

The choice of encoder resolution is very wide and is constrained by the module’s maxi-

mum pulse count at the high end and measurement resolution for speed at the low end.

A Channel

Count Up

Count Down

B Channel

Quadrature

Signal

FIGURE 40. Quadrature encoder output waveform

1 Pulse

= 4 Transitions

= 4 Counts

LED light source

Stationary mask

Photodetector

Rotating

encoder disk

FIGURE 41. Typical quadrature encoder construction