Closed Loop Position Mode

86 AX2550 Motor Controller User’s Manual Version 1.9b. June 1, 2007

Position Sensor Selection

The AX2550 may be used with the following kind of sensors:

• Potentiometers

• Hall effect angular sensors

• Optical Encoders (with Encoder Module)

The first two are used to generate an analog voltage ranging from 0V to 5V depending on

their position. They will report an absolute position information at all times.

Optical encoders report incremental changes from a reference which is their initial position

when the controller is powered up or reset. Using Optical Encoders in this mode is possi-

ble but requires special handling that is described in Figure , “Using the Encoder to Track

Position,” on page 81.

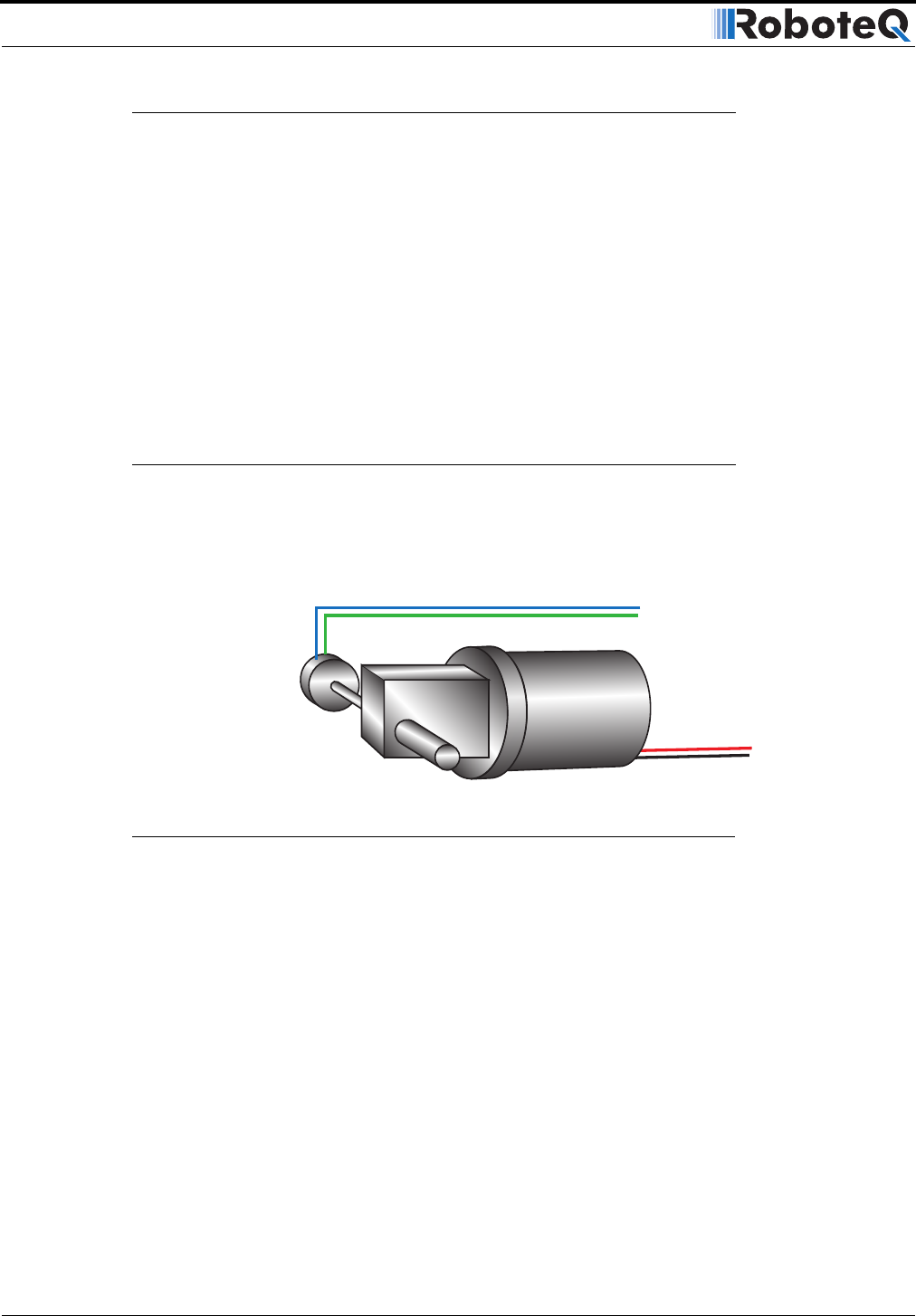

Sensor Mounting

Proper mounting of the sensor is critical for an effective and accurate position mode opera-

tion. Figure 54 shows a typical motor, gear box, and sensor assembly.

The sensor is composed of two parts:

• a body which must be physically attached to a non-moving part of the motor assem-

bly or the robot chassis, and

• an axle which must be physically connected to the rotating part of the motor you

wish to position.

A gear box is necessary to greatly increase the torque of the assembly. It is also necessary

to slow down the motion so that the controller has the time to perform the position control

algorithm. If the gearing ratio is too high, however, the positioning mode will be very slug-

gish.

A good ratio should be such that the output shaft rotates at 1 to 10 rotations per second

(60 to 600 RPM) when the motor is at full speed.

Position Sensor

Gear box

Position Feedback

FIGURE 54. Typical motor/potentiometer assembly in Position Mode