Installing, Connecting and Using the Encoder Mod-

76 AX2550 Motor Controller User’s Manual Version 1.9b. June 1, 2007

Cable Length and Noise Considerations

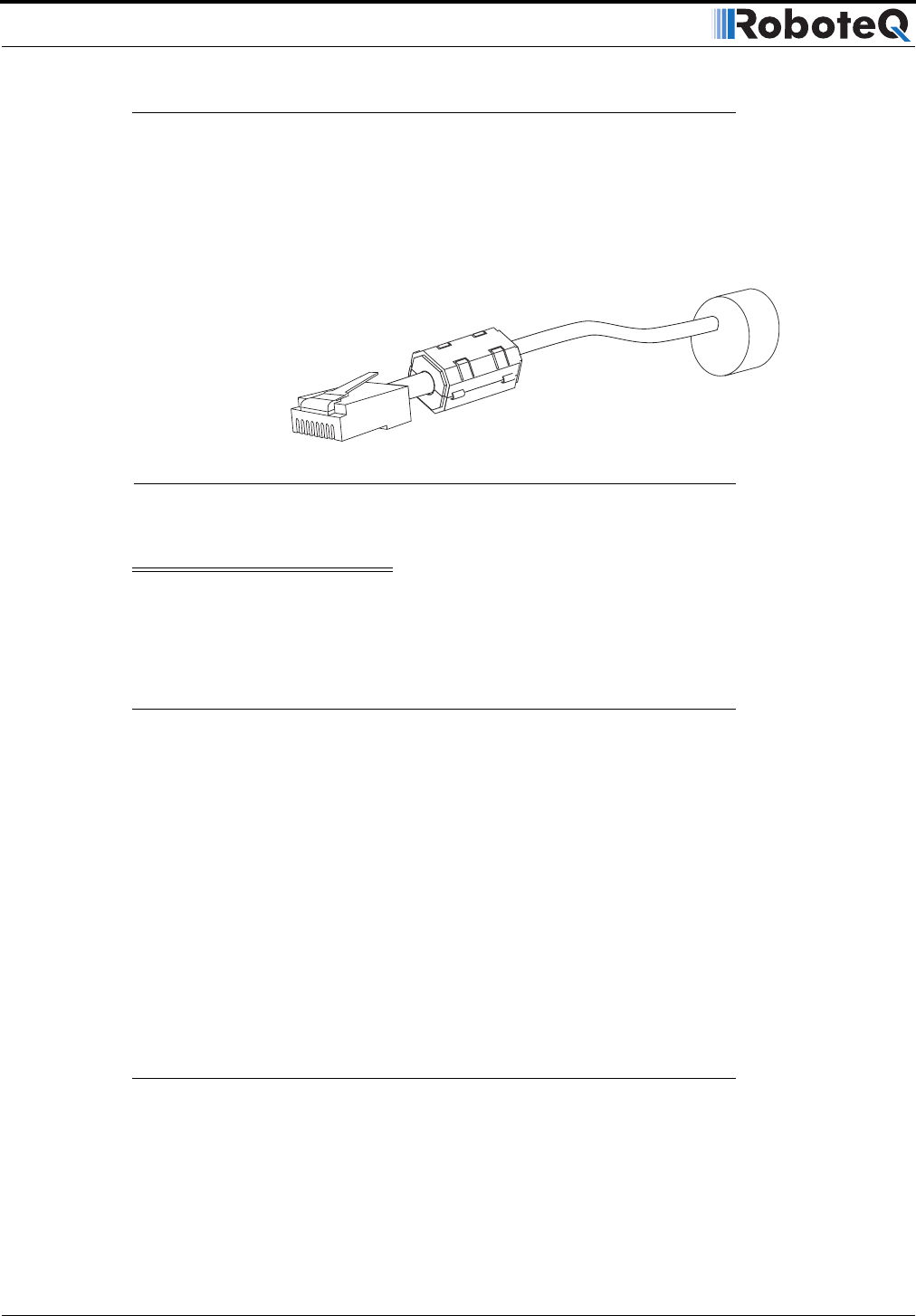

Cable should not exceed one 3’ (one meter) to avoid electrical noise to be captured by the

wiring. A ferrite core filter must be used for length beyond 2’ (60 cm). For longer cable

length use an oscilloscope to verify signal integrity on each of the pulse channels and on

the power supply.

Important Warning

Excessive cable length will cause electrical noise to be captured by the controller and

cause erratic functioning that may lead to failure. In such situation, stop operation

immediately.

Motor - Encoder Polarity Matching

When using the Encoder module for closed loop speed control, it is imperative that when

the motor is turning in the forward direction, the counter increments its value and a posi-

tive speed value is measured.

Using the PC utility, it is possible to exercise the motors and view the encoder readings.

See “Encoder Testing and Setting Using the PC Utility” on page 83.

If the Encoder counts backwards when the motor moves forward, correct this by either:

1- Swapping Channel A and Channel B on the encoder connector. This will cause the

encoder module to reverse the count direction, or

2- Swapping the leads on the motor. This will cause the motor to rotate in the opposite

direction.

Voltage Levels, Thresholds and Limit Switches

The encoder module’s input uses a comparator to reshape the encoder’s output signal. If

the signal is below a programmable threshold level, then it is considered to be 0. If above,

it is considered to be 1. The output of this comparator feeds the quadrature detector and

counters.

Ferrite Core

Encoder

FIGURE 47. Use ferrite core on cable length beyond 2’ or 60cm