Chapter 6 Control Modes of Operation|ASDA-B Series

Revision February 2008, Doc. Name: 2006PDD23000009 6-5

DI Name DI Status Selected Electronic Gear

Not select (Note 1) P1-44, P1-45

0 P1-44, P1-45

GNUM0

1 P1-44, P1-45

NOTE

1) DI signal can be selected by parameter P2-10 to P2-15 and Table 7.A. If uses only need to

use one group of electronic gear, it allows users not to select GNUM0.

P1 - 45▲

GR2 Electronic Gear Ratio (Denominator) Communication Addr.: 012DH

Default: 1 Related Section:

Applicable Control Mode: P Section 6.2.4, P1-15, P1-44

Unit: pulse DI GNUM0(11) in Table 7.A

Range: 1 ~ 32767

Settings:

Please set electronic gear ratio when the servo drive is Off. As the wrong setting can cause

motor to run chaotically (out of control) and it may lead to personnel injury, therefore, ensure to

observe the following rule when setting P1-44, P1-45.

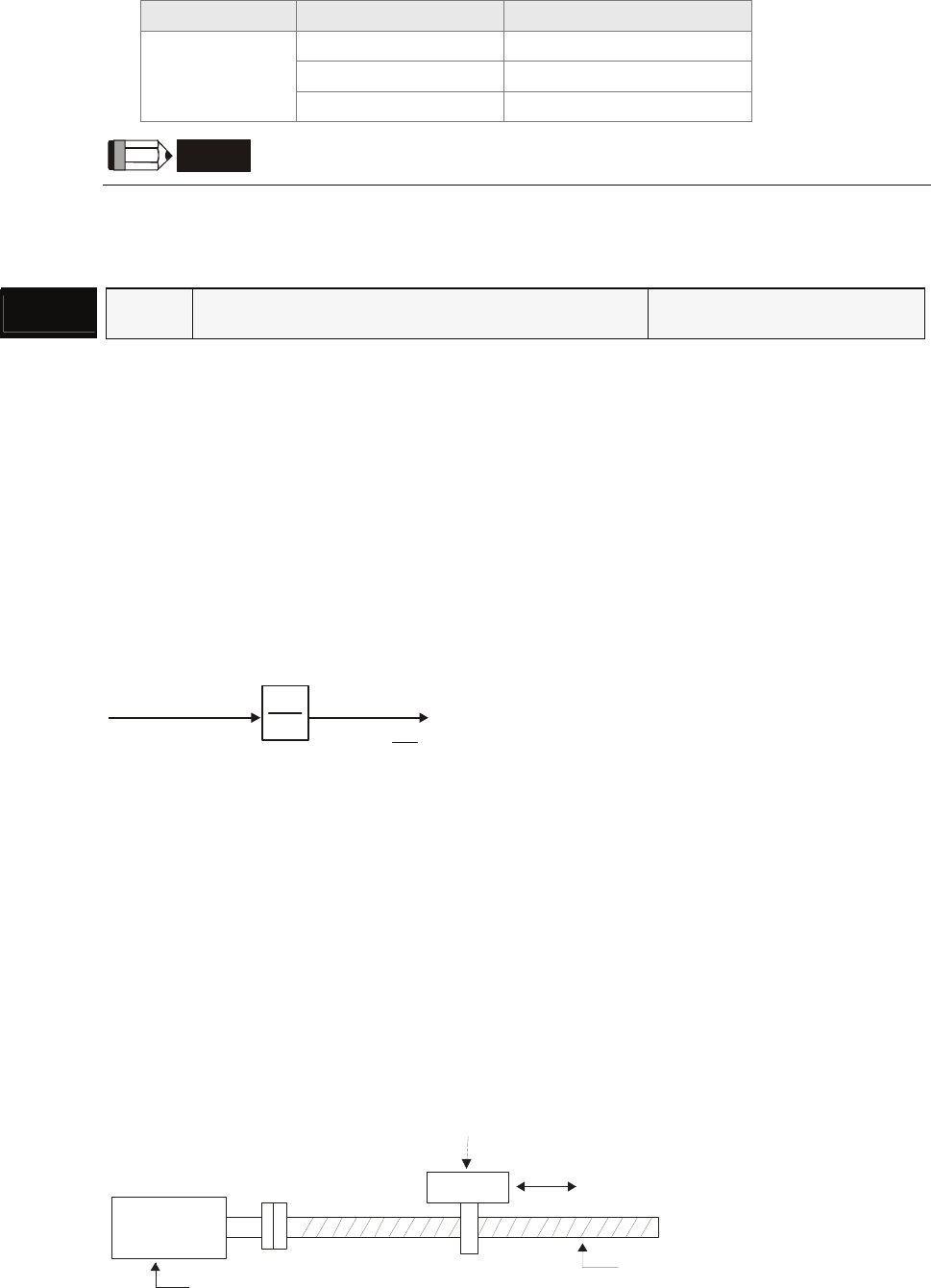

The electronic gear ratio settings:

f1

f2 = f1 x

N

M

N

M

Pulse input

Position

command

The electronic gear ratio setting range must be within: 1/50<N/M<200.

The electronic gear function provides easy travel distance ratio change. However, the over high

electronic gear ratio will command the motor to move not smoothly. At this time, the users can use low-

pass filter parameter to improve this kind of situation. For example, assume that the electronic gear ratio

is equal to 1 and the encoder pulse per revolution is 10000ppr, if the electronic gear ratio is changed to

0.5, then the motor will rotate one pulse when the command from external controller is two pulses.

For example, after the proper electronic gear ratio is set, the reference travel distance is 1 μm/pulse, the

machinery will become easier to be used.

Travel distance per pulse = T

Motor (encoder signal output: A/B, Z)

Encoder PPR: 2500 pulse

Ball Screw Pitch: 3mm

Workpiece (Table or Load

)

f1: Pulse input f2: Position command

N: Numerator, the setting value of P1-15 or P1-44

M: Denominator, the setting value of P1-45