General Operation

46 AX1500 Motor Controller User’s Manual Version 1.9b. June 1, 2007

Important Warning

Depending on the load’s weight and inertia, a quick acceleration can cause consider-

able current surges from the batteries into the motor. A quick deceleration will cause

an equally large, or possibly larger, regeneration current surge. Always experiment

with the lowest acceleration value first and settle for the slowest acceptable value.

Command Control Curves

The AX1500 can also be set to translate the joystick or RS232 motor commands so that the

motors respond differently whether or not the joystick is near the center or near the

extremes.

The controller can be configured to use one of 5 different curves independently set for

each channel.

The factory default curve is a “linear” straight line, meaning that after the joystick has

moved passed the deadband point, the motor’s speed will change proportionally to the joy-

stick position.

Two “exponential’ curves, a weak and a strong, are supported. Using these curves, and

after the joystick has moved past the deadband, the motor speed will first increase slowly,

increasing faster as the joystick moves near the extreme position. Exponential curves allow

better control at slow speed while maintaining the robot’s ability to run at maximum speed.

Two “logarithmic” curves, a weak and a strong, are supported. Using these curves, and

after the joystick has moved past the deadpoint, the motor speed will increase rapidly, and

then increase less rapidly as the joystick moves near the extreme position.

The graph below shows the details of these curves and their effect on the output power as

the joystick is moved from its center position to either extreme. The graph is for one joy-

stick only. The graph also shows the effect of the deadband setting.

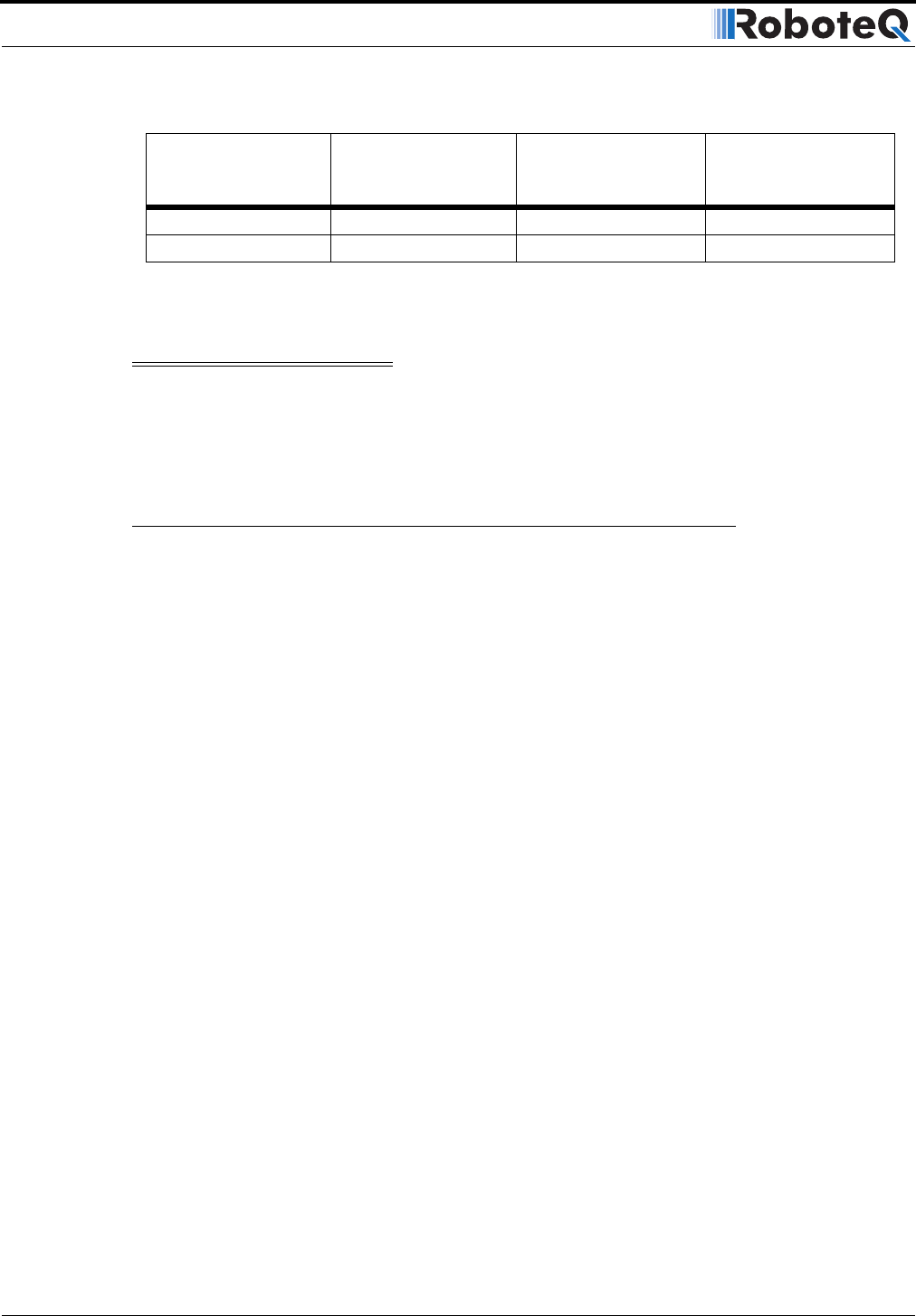

15 Hex - 17.97% 0.089 second

05 Hex 5 18.75% 0.085 second

TABLE 4. Acceleration setting table

Acceleration

Setting Using

RS232

Acceleration

Setting Using

Switches

%Acceleration per

16ms

Time from 0 to

max speed