SJ300 Inverter

Getting Started

1–9

General

Specifications

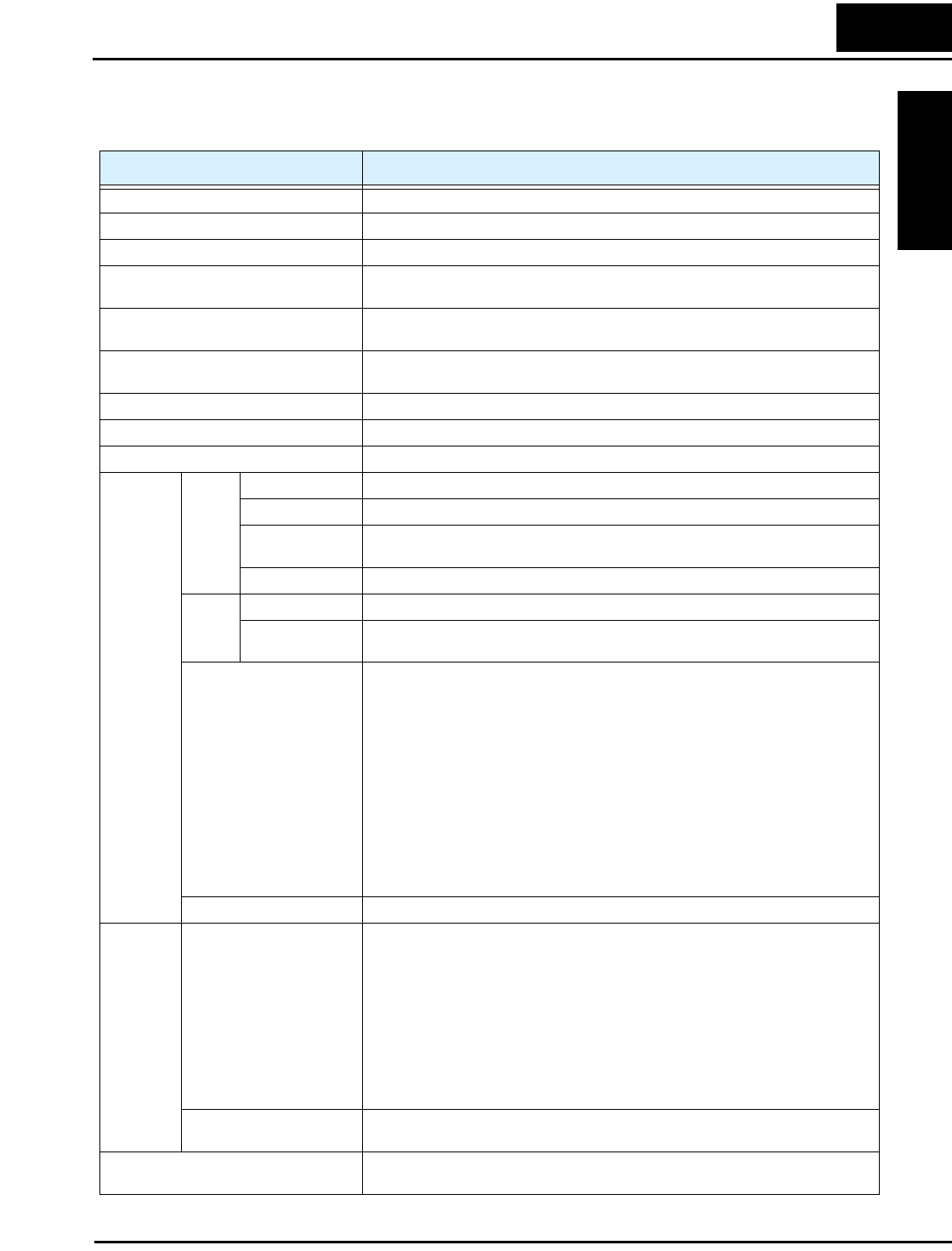

The following table (continued on next page) applies to all SJ300 inverter models.

Item General Specifications

Protective enclosure *1, *11 IP20 (NEMA 1)

Control method Line-to-line sine wave pulse-width modulation (PWM) control

Output frequency range *4 0.1 to 400 Hz

Frequency accuracy Digital command: ± 0.01% of the maximum frequency

Analog command: ± 0.2% (25°C ± 10°C)

Frequency setting resolution Digital: ± 0.01 Hz; Analog: (max. frequency)/4000, [O] terminal: 12-bit 0 to 10V;

[OI] terminal: 12-bit, 4-20mA; [O2] terminal: 12-bit -10 to +10V

Volt./Freq. characteristic *5 V/F optionally variable (30 to 400Hz base frequency), V/F control (constant torque,

reduced torque), sensorless vector control

Speed fluctuation ± 0.5% (sensorless vector control)

Overload capacity (output current) 150% for 60 seconds, 200% (180% for 75kW / 100HP and larger) for 0.5 seconds

Acceleration/deceleration time 0.01 to 3600 sec., (linear curve profiles, accel./decel. selection), two-stage accel./decel.

Input

signal

Freq.

setting

Operator keypad Up and Down keys / Value settings

Potentiometer Analog setting via potentiometer on operator keypad

External signal *8 0 to 10 VDC (input impedance 10k Ohms), 4 to 20 mA (input impedance 250 Ohms),

Potentiometer (1k to 2k Ohms, 2W)

Serial port RS485 interface

FW/RV

Run

Operator panel Run key / Stop key (change FW/RV by function command)

External signal FW Run/Stop (NO contact), RV set by terminal assignment (NC/NO),

3-wire input available

Intelligent Input

terminals (assign eight

functions to terminals)

RV (reverse run/stop), CF1~CF4 (multi-speed select), JG (jogging), DB (external DC

braking), SET (set 2nd motor data), 2CH (2-stage accel./decel.), FRS (free-run stop),

EXT (external trip), USP (unattended start protection), CS (commercial power source),

SFT (software lock), AT (analog input voltage/current select), SET3 (set 3rd motor

data), RS (reset inverter), STA (start, 3-wire interface), STP (stop, 3-wire interface),

F/R (FW/RV 3-wire interface), PID (PID ON/OFF), PIDC (PID reset), CAS (control

gain setting), UP (remote control Up function, motorized speed pot.), DWN (remote

control Down function, motorized speed pot.), UDC (remote control data clearing),

OPE (Operator control), SF1-SF7 (Multispeed bits 0-7), OLR (Overload limit change),

TL (torque limit enable), TRQ1 (torque limit selection bit 1, LSB), TRQ2 (torque limit

selection bit 2, MSB), PPI (Proportional / Proportional/Integral mode selection), BOK

(Brake confirmation signal), ORT (Orientation – home search), LAC (LAC: LAD

cancel), PCLR (Position deviation reset), STAT (pulse train position command input

enable), NO (not selected)

Thermistor input One terminal (PTC characteristics)

Output

signal

Intelligent Output terminals

(assign six functions to five

open collector outputs and

one relay NO-NC contact)

RUN (run signal), FA1 (Frequency arrival type 1 – constant speed), FA2 (Frequency

arrival type 2 – over-frequency), OL (overload advance notice signal 1), OD (Output

deviation for PID control), AL (alarm signal), FA3 (Frequency arrival type 3 – at-

frequency), OTQ (over-torque signal), IP (Instantaneous power failure signal), UV

(Under-voltage signal), TRQ (In torque limit), RNT (Run time over), ONT (Power-ON

time over), THM (thermal alarm), BRK (Brake release signal), BER (Brake error

signal), ZS (Zero speed detect), DSE (speed deviation maximum), POK (Positioning

completion), FA4 (Frequency arrival type 4 – over-frequency 2), FA5 (Frequency arrival

type 5 – at-frequency 2), OL2 (Overload notice advance signal 2), Terminals 11-13 or

11-14 automatically configured as AC0-AC2 or AC0-AC3 per alarm code output selec-

tion)

Intelligent monitor output

terminals

Analog voltage monitor, analog current monitor (8-bit resolution), and PWM output, on

terminals [AM], [AMI], [FM]

Display monitor Output frequency, output current, motor torque, scaled value of output frequency, trip

history, I/O terminal condition, input power, output voltage