Operating the MC9000-G

2-35

Indicator LED Bar

The Indicator LED bar provides a visual indication of the scan status, see Figure 1-1 on page 1-3.

Scanning Considerations

Typically, scanning is a simple matter of aim, scan/decode and a few quick trial efforts master it.

However, two important considerations can be used to optimize any scanning performance:

• Range

Any scanning device decodes well over a particular working range — minimum and

maximum distances from the bar code. This range varies according to bar code density and

scanning device optics.

Scanning within range brings quick and constant decodes; scanning too close or too far

away prevents decodes. Move the scanner closer and further away to find the right working

range for the bar codes being scanned. However, the situation is complicated by the

availability of various integrated scanning modules. The best way to specify the appropriate

working range per bar code density is through a chart called a decode zone for each scan

module. A decode zone simply plots working range as a function of minimum element widths

of bar code symbols.

• Angle

Scanning angle is important for promoting quick decodes. When laser beams reflect directly

back into the scanner from the bar code, this specular reflection can “blind” the scanner.

To avoid this, scan the bar code so that the beam does not bounce directly back. But don’t

scan at too sharp an angle; the scanner needs to collect scattered reflections from the scan

to make a successful decode. Practice quickly shows what tolerances to work within.

Contact the Symbol Support Center if chronic scanning difficulties develop.

Decoding of properly printed bar codes should be quick and effortless.

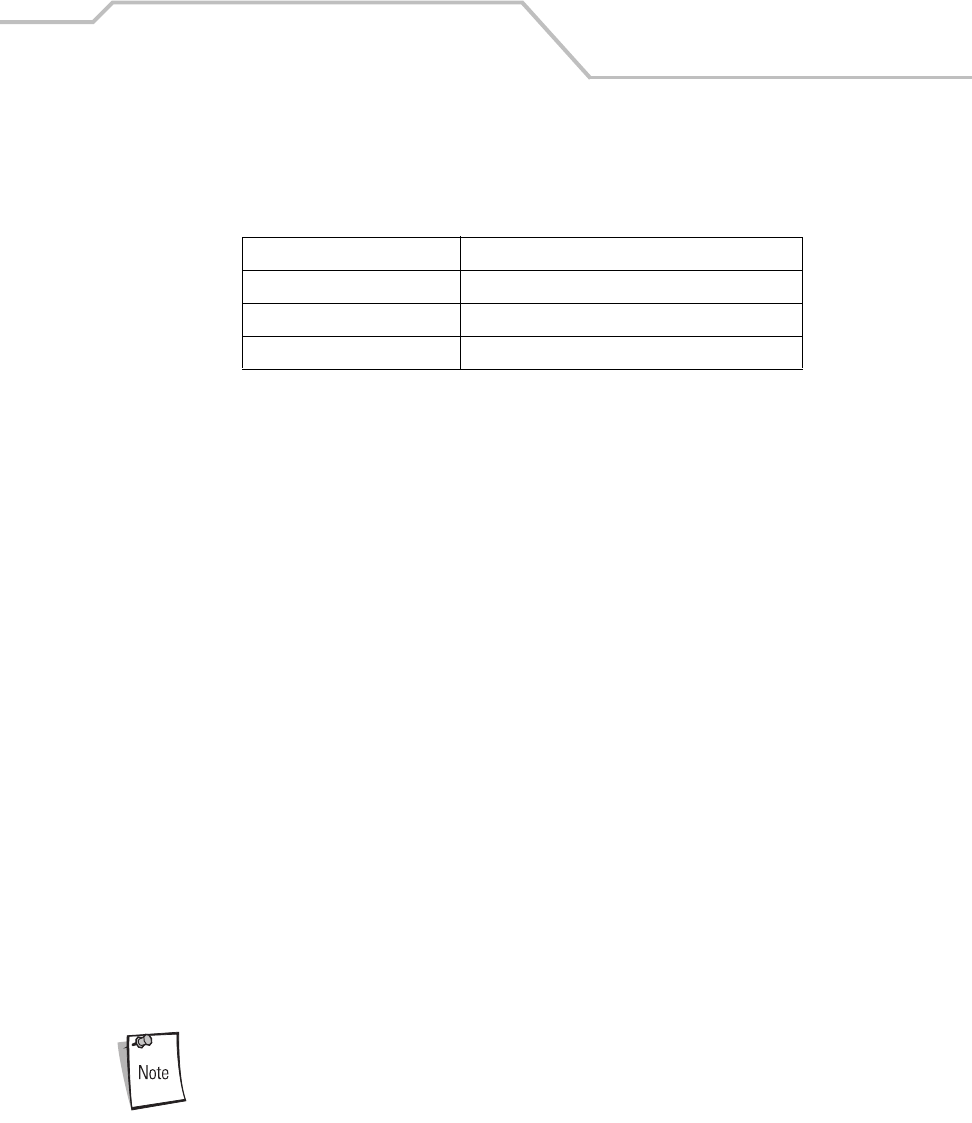

Table 2-11. Scan LED Indicators

LED Status Indication

Off Not scanning.

Solid Red Laser enabled, scanning in process.

Solid Green Successful decode.