62

Advanced Function

Starting Machine Analyzer operation

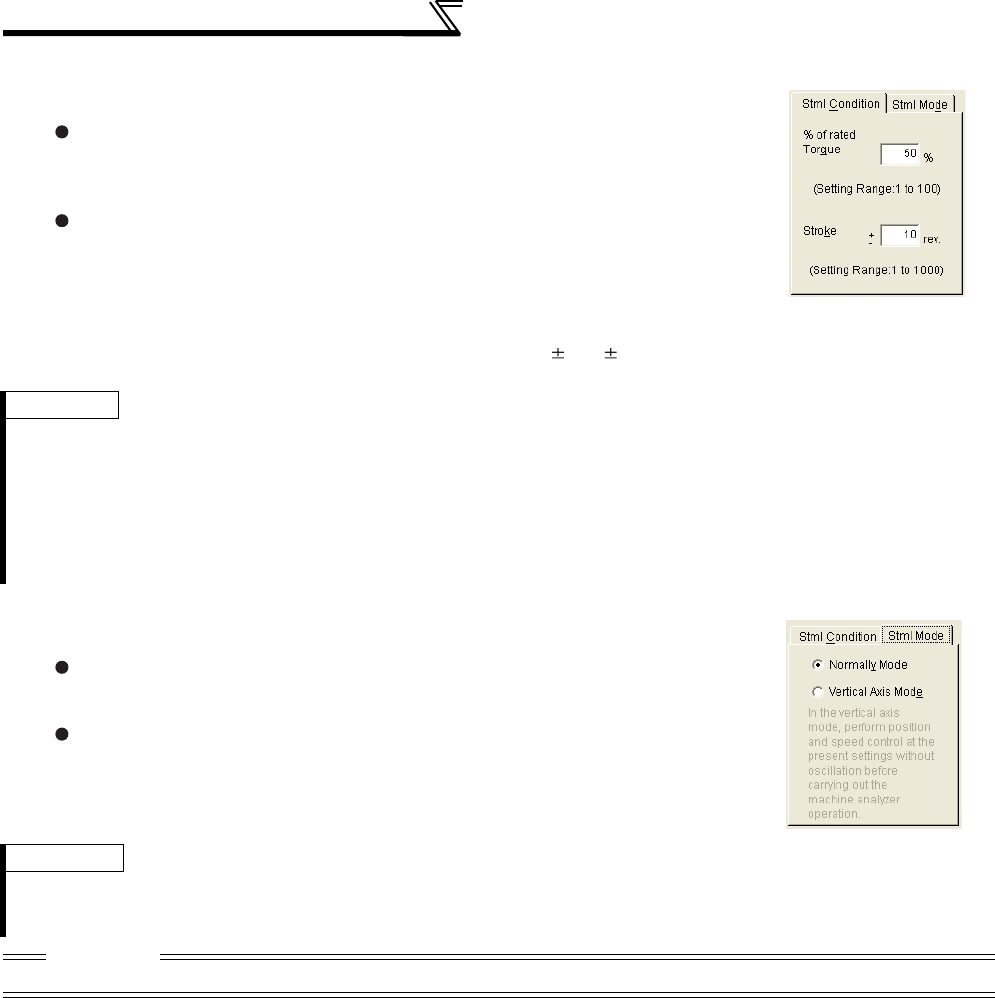

(1)Set Stml condition.

" % of rated Torque"................Set the maximum oscillation torque for oscillating the

motor under a random torque command.

(Setting range: 1 to 100%)

"Stroke"...................................Set the rotation range permitted for oscillation,

beginning at the motor position when Machine Analyzer

is started.

If this range is exceeded, Machine Analyzer is stopped

immediately, and the motor is coasted in the vertical

shaft mode or is coasted after deceleration in the

normal mode.(Setting range: 1 to 1000)

REMARKS

• If a measurement result varies, accurate measurement may not have been made.

• Accurate measurement may not be made in a mechanical system whose oscillation torque is too small or whose

friction is large.

In such a case, increase the oscillation torque and restart Machine Analyzer.

• If the oscillation torque is too large relative to the load inertia moment, an overcurrent or similar alarm may occur.

At that time, reduce the oscillation torque and restart Machine Analyzer.

• Starting oscillation automatically switches to the torque control mode and shifts the position. Before starting operation

after oscillation, therefore, always make a home position return.

(2)Select the Stml mode

"Normal mode".......................The inverter operates in the torque control mode and

oscillates the motor randomly.

"Vertical Axis Mode".................A servo lock is placed in the speed control mode,

preventing a fall.

Gain setting must have been made to ensure that

stable servo lock operation will be performed.

REMARKS

In "Vertical Axis Mode"

• The accuracy of 100Hz or less on the low frequency side may become poor.

• The measurement accuracy becomes poor if the position loop gain (Pr. 422) is set too high.

CAUTION

When the machine is a vertical axis, always perform this function in the "Vertical Axis Mode" since a fall may occur.