4-22

ENG

VALVES AND VALVE SPRINGS

NOTE:

CAUTION:

EAS00240

CHECKING THE VALVE SEATS

The following procedure applies to all of the

valves and valve seats.

1. Eliminate:

Scarbon deposits

(from the valve face and valve seat)

2. Check:

Svalve seat

Pitting/wear ! Replace the cylinder head.

3. Measure:

Svalve seat width

a

Out of specification ! Replace the cylinder

head.

Valve seat width

Intake: 0.9 X 1.1 mm

Exhaust: 0.9 X 1.1 mm

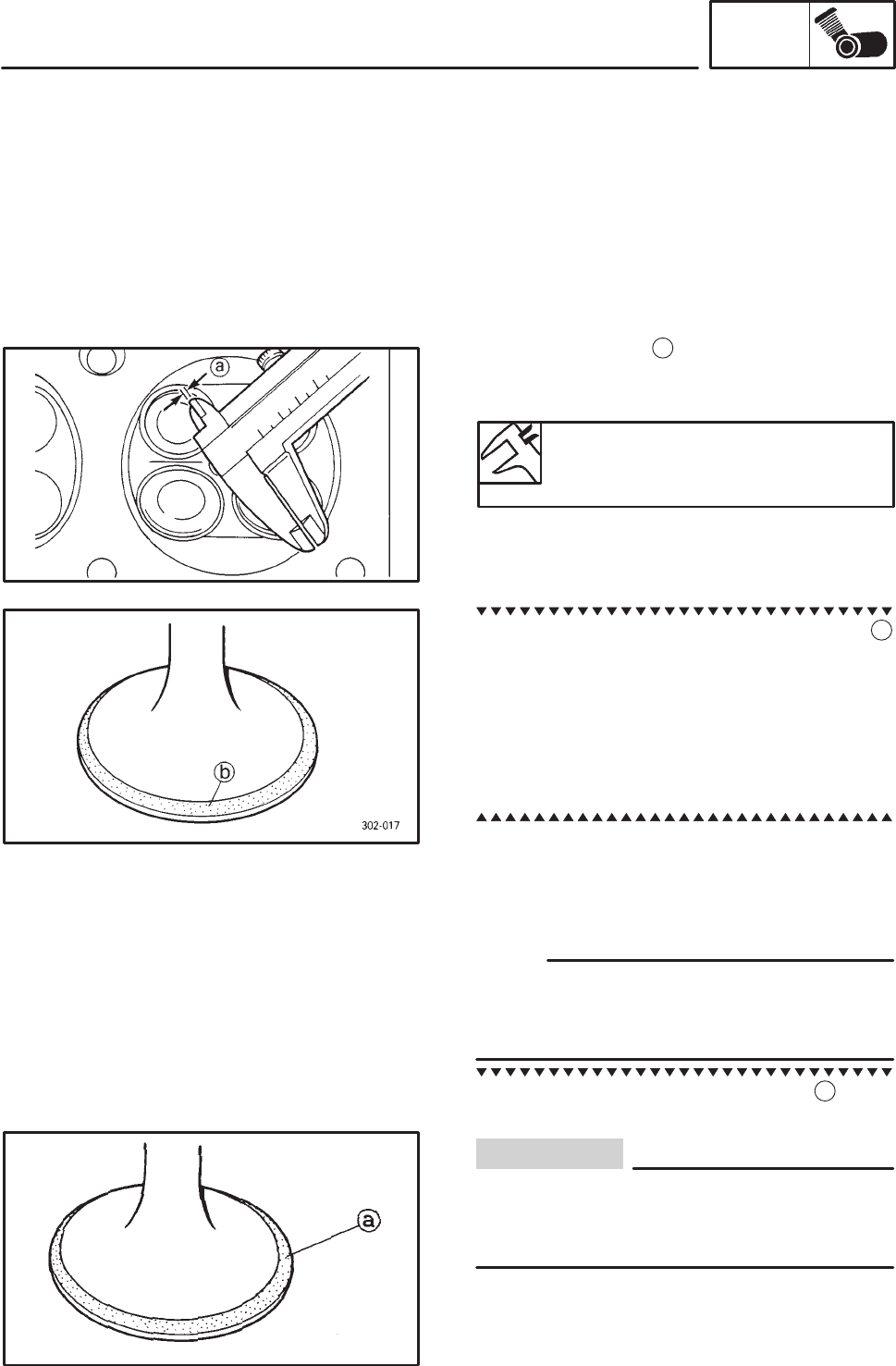

a. Apply Mechanic’s blueing dye (Dykem)

b

onto the valve face.

b. Install the valve into the cylinder head.

c. Press the valve through the valve guide and

onto the valve seat to make a clear pattern.

d. Measure the valve seat width. Where the

valve seat and valve face contacted one

another, the blueing will have been removed.

4. Lap:

Svalve face

Svalve seat

After replacing the cylinder head or replacing

the valve and valve guide, the valve seat and

valve face should be lapped.

a. Apply a coarse lapping compound

a

to the

valve face.

Do not let the lapping compound enter the

gap between the valve stem and the valve

guide.

b. Apply molybdenum disulfide oil onto the

valve stem.

c. Install the valve into the cylinder head.