1

section level 1 1

figure bi level 1

table_big level 1

restart lowapp ARestart oddapp: ARestarts for autonumbers that do not restart in

each chapter. figure bi level 1, reset table_big level 1, reset chap_big level 1, reset1

Lowapp Alwbox restart evenap:A1app_big level 1, resetA figure_ap level 1, reset

table_ap level 1, reset figure level 1, reset Figure 1. table level 1, reset Table 1.

these restarts oddbox reset: 1evenbox reset: 1must be in the header frame of

chapter 1. a:ebx, l 1 resetA a:obx:l 1, resetA a:bigbx level 1 resetA a:ftr level 1 resetA

c:ebx, l 1 reset1 c:obx:l 1, reset1 c:bigbx level 1 reset1 c:ftr level 1 reset1

Reminders for autonumbers that need to be restarted manually (first instance will

always be 4) let_in level 1: A. B. C. letter level 1:A.B.C. num level 1: 1. 2. 3.

num_in level 1: 1. 2. 3. rom_in level 1: I. II. III. roman level 1: I. II. III. steps level 1:

1. 2. 3.

restart lowapp ARestart oddapp: ARestarts for autonumbers that do not restart in

each chapter. figure bi level 1, reset table_big level 1, reset chap_big level 1, reset1

Lowapp Alwbox restart evenap:A1app_big level 1, resetA figure_ap level 1, reset

table_ap level 1, reset figure level 1, reset Figure 1. table level 1, reset Table 1.

these restarts oddbox reset: 1evenbox reset: 1must be in the header frame of

chapter 1. a:ebx, l 1 resetA a:obx:l 1, resetA a:bigbx level 1 resetA a:ftr level 1 resetA

c:ebx, l 1 reset1 c:obx:l 1, reset1 c:bigbx level 1 reset1 c:ftr level 1 reset1

Reminders for autonumbers that need to be restarted manually (first instance will

always be 4) let_in level 1: A. B. C. letter level 1:A.B.C. num level 1: 1. 2. 3.

num_in level 1: 1. 2. 3. rom_in level 1: I. II. III. roman level 1: I. II. III. steps level 1:

1. 2. 3.

1-1

GFK-0787B

Chapter 1 Introduction

Genius Modular Redundancy (GMR ) has been developed by GE Fanuc Automation and Silvertech

Limited of the United Kingdom. Silvertech has many years experience applying GE Fanuc products to

high-integrity safety system applications such as Emergency Shutdown and Fire & Gas Detection in the

petrochemical / oil and gas industries. They have captured this expertise in the GMR system software.

GMR is a high-reliability, high-availability redundancy system that provides a scalable solution for many

types of redundancy applications, including critical TMR (Triple Modular Redundancy) applications.

TÜV has certified GMR for classification to these requirements: triplex Class 5, duplex Class 4 and 5,

and simplex Class 4 according to the DIN V19250/DIN V VDE 081 standards. For use of the GMR

system in a TÜV approved safety critical installation, refer to information in Appendix A.

The GMR system is based on standard, off-the-shelf hardware. It utilizes field-proven Series 90-70

PLC and Genius I/O products. Enhancements have been incorporated into the standard PLC CPU,

bus controller, and several Genius I/O blocks specifically for use in GMR systems. These enhanced

products, together with GMR system software, provide input voting by the PLCs, output voting,

support for both discrete and analog I/O, automatic testing of discrete inputs and outputs, and

extensive fault-monitoring capabilities for the application program.

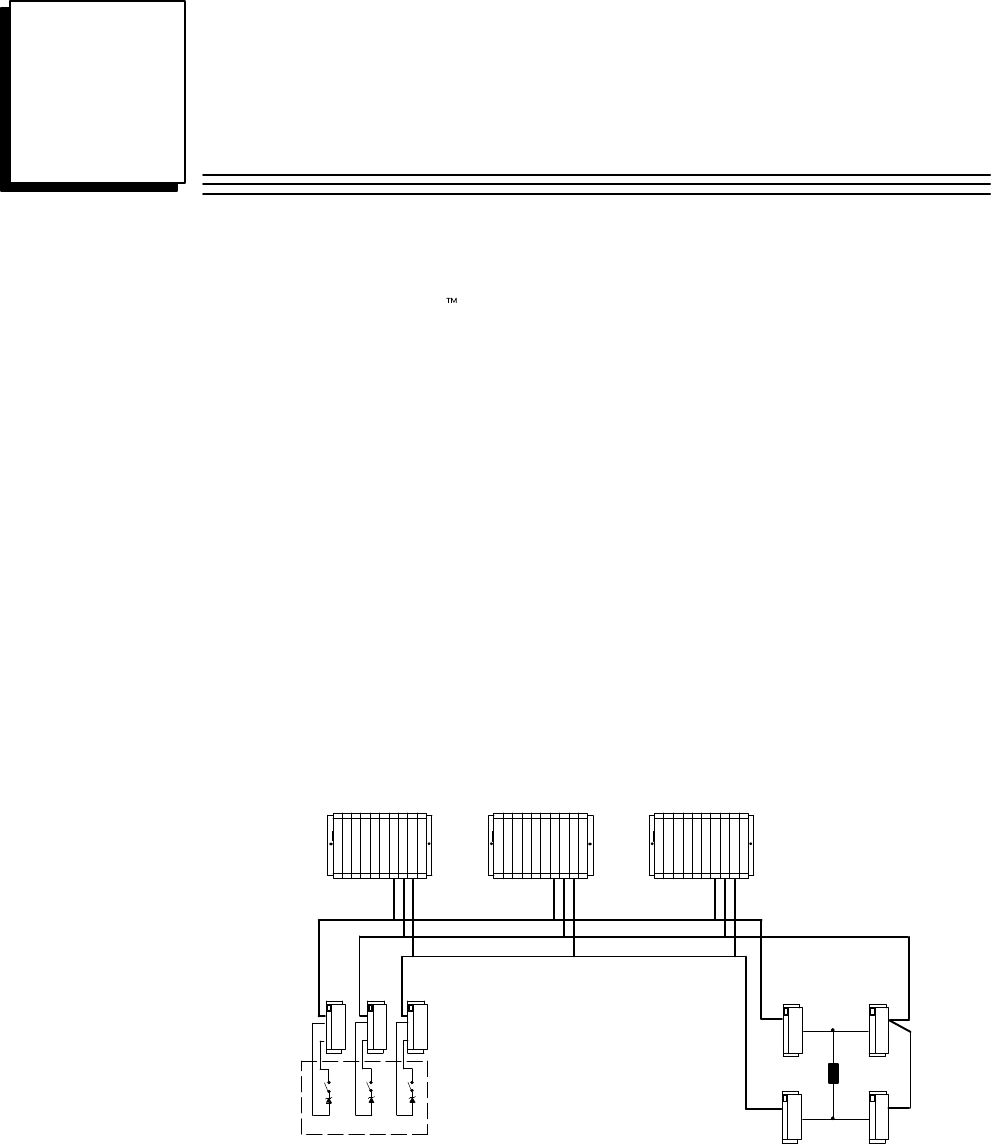

A basic GMR system consists of groups of Genius blocks gathering data from multiple or single

sensors, multiple PLCs running the same application program, and groups of Genius blocks

controlling shared output loads. Communications between the blocks and PLCs and among the

PLCs is provided by the Genius bus.

Triple Input Sensors

Triple Genius Busses

Triple PLCs

Load

GMR provides great configuration flexibility. A system can include 1, 2, or 3 PLCs. There can be just one

I/O subsystem, as represented above, or more than one. Each I/O subsystem can include 1, 2, or 3 busses.

A bus can serve up to a total of 32 devices (I/O blocks, PLCs, and a Hand-held Monitor). The system can

include both non-redundant I/O blocks and individual non-redundant points on redundant blocks.