Introduction to Variable-Frequency Drives

The Purpose of Motor Speed Control for Industry

Hitachi inverters provide speed control for 3-phase AC induction motors. You connect

AC power to the inverter, and connect the inverter to the motor. Many applications

benefit from a motor with variable speed, in several ways:

• Energy savings – HVAC

• Need to coordinate speed with an adjacent process – textile and printing presses

• Need to control acceleration and deceleration (torque)

• Sensitive loads – elevators, food processing, pharmaceuticals

What is an Inverter

The term

inverter

and

variable-frequency drive

are related and somewhat

interchangeable. An electronic motor drive for an AC motor can control the motor’s

speed by

varying the frequency

of the power sent to the motor.

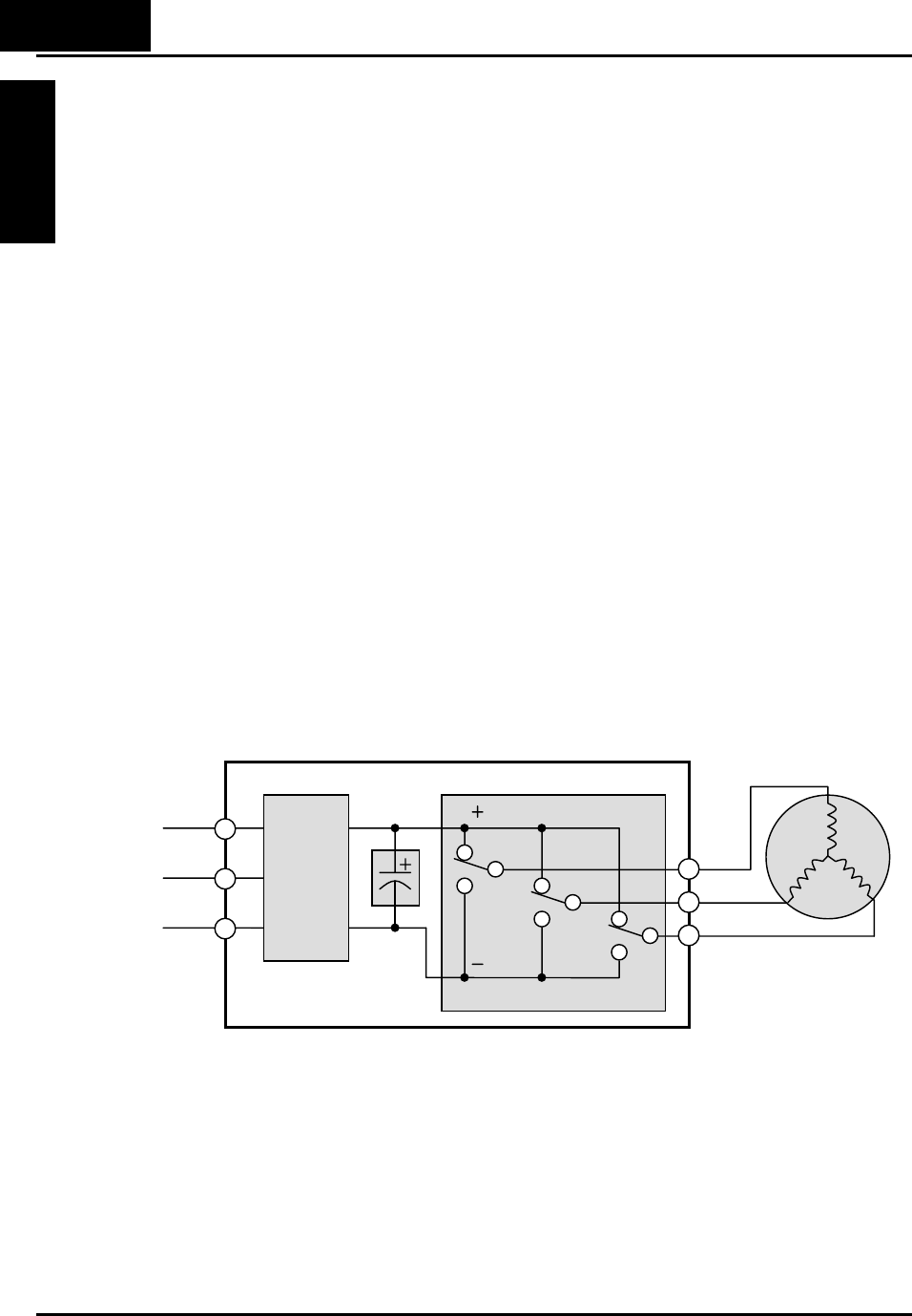

An inverter, in general, is a device that converts DC power to AC power. The figure

below shows how the variable-frequency drive employs an internal inverter. The drive

first converts incoming AC power to DC through a rectifier bridge, creating an internal

DC bus voltage. Then the inverter circuit converts the DC back to AC again to power the

motor. The special inverter can vary its output frequency and voltage according to the

desired motor speed.

The simplified drawing of the inverter shows three double-through switches. In Hitachi

inverters, the switches are actually IGBTs (insulated gate bipolar transistors). Using a

commutation algorithm, the microprocessor in the drive switches the IGBTs on and off

at a very high speed to create the desired output waveforms. The inductance of the

motor windings helps smooth out the pulses.

Rectifier

Motor

InverterConverter

Internal

DC Bus

Power

Input

L1

L2

L3

U/T1

V/T2

W/T3

Variable-frequency Drive

1−12

Getting started