Monitoring Parameters with the Display

After using the keypad for parameter editing, it’s a

good idea to switch the inverter from Program Mode to

Monitor Mode. The PRG LED will be OFF, and the

Hertz or Ampere LED indicates the display units.

For the powerup test, monitor the motor speed

indirectly by viewing the inverter’s output frequency.

The

output frequency

must not be confused with

base

frequency

(50/60 Hz) of the motor, or the

carrier

frequency

(switching frequency of the inverter, in the kHz range). The monitoring

functions are in the “D” list, located near the top left of the “Keypad Navigation Map”on

page 2-26.

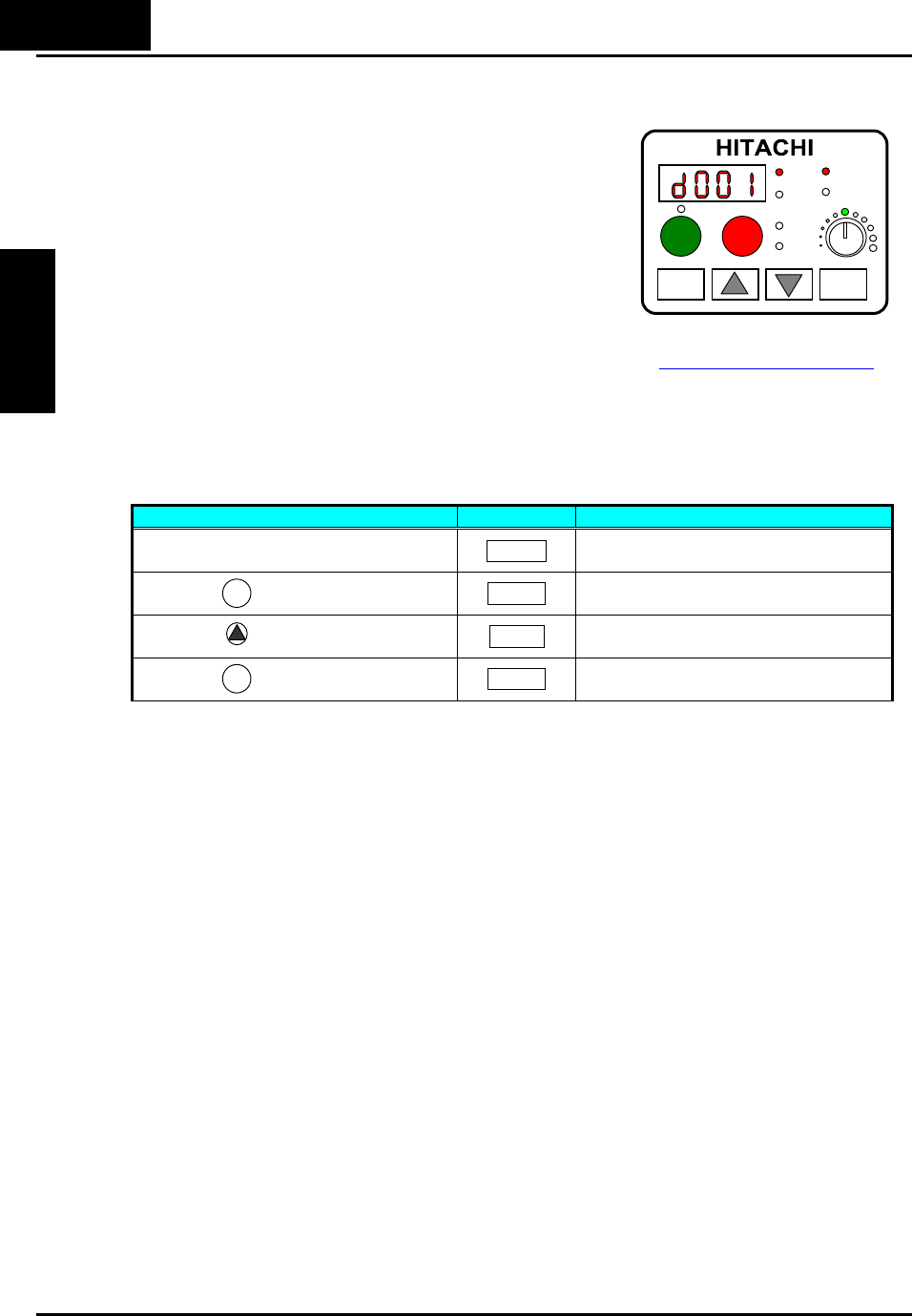

Output frequency (speed) monitor – Resuming keypad operation from the previous table,

follow the steps below. Or instead, you can simply power cycle the inverter, which

automatically sets the display to D001 (output frequency value).

Action Display Func./Parameter

(Starting point)

H004

Motor poles parameter

Press the key.

H- - -

“H” Group selected

Press the key.

d001

Output frequency selected

Press the key. 0.0 Output frequency displayed

When the inverter displays a monitor value, the PRG LED is OFF. This confirms the

inverter is not in programming mode, even while you are selecting the particular

monitoring parameter. The display shows the current speed (is zero at this point). The

Hz LED will be ON, indicating the display units. For current, the Amperes LED will be

ON.

Running the Motor

If you have programmed all the parameters up to this point, you’re ready to run the

motor! First, review this checklist:

1. Verify the power LED is ON. If not, check the power connections.

2. Verify the Potentiometer Enable LED is ON. If it is OFF, check the A001 setting.

3. Verify the Run Key Enable LED is ON. If it is OFF, check the A002 setting.

4. Verify the PRG LED is OFF. If it is ON, review the instructions above.

5. Make sure the motor is disconnected from any mechanical load.

6. Turn the potentiometer to the minimum position (completely counter clock-wise).

7. Now, press the RUN key on the keypad. The RUN LED will turn ON.

8. Slowly increase the potentiometer setting in clockwise fashion. The motor should

start turning.

9. Press the STOP key to stop the motor rotation.

1

FUNC

FUNC

2−34

Inverter Mounting

and installation

PRG

RUN

Hz

RUN

A

2

POWER

A

LARM

STOP

RESET

1

FUNC STR