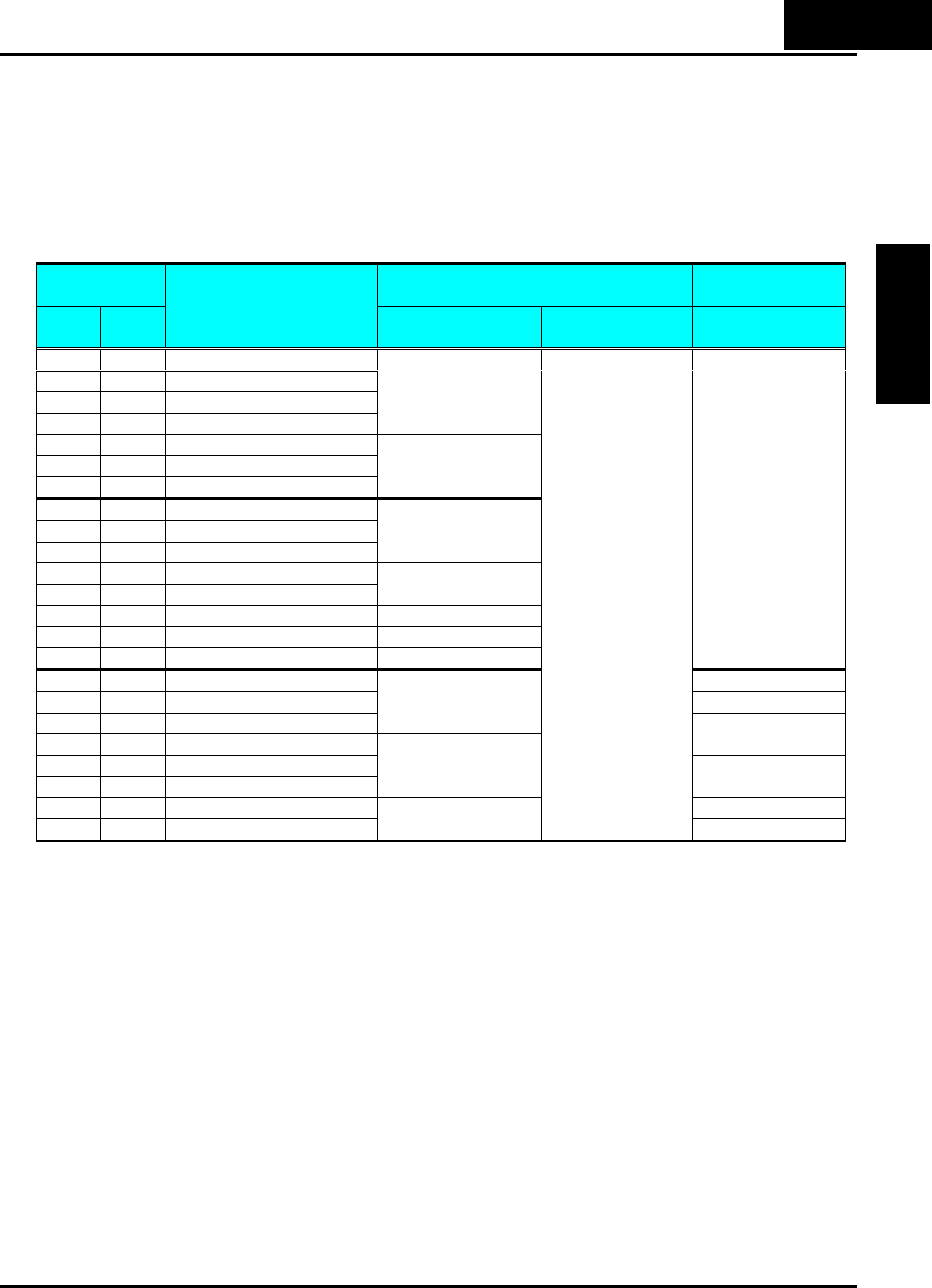

Determining Wire and Fuse Sizes

The maximum motor currents in your application determines the recommended wore

size. The following table gives the wire size in AWG. The “Power Lines” column applies

to the inverter input power, output wires to the motor, the earth ground connection, and

any other components shown in the “Basic System Description” on page 2-7. The “Signal

Lines” column applies to any wire connecting to the two green connectors just inside the

front cover panel.

Motor Output Wiring

Applicable

equipment

kW HP

Inverter Model

Power Lines Signal Lines

Fuse (UL-rated,

class J, 600V)

0.2 1/4 X200-002SFEF

0.4 1/2 X200-004SFEF

0.55 3/4 X200-005SFEF

0.75 1 X200-007SFEF

AWG14 / 2.1mm

2

1.1 1 1/2 X200-011SFEF

1.5 2 X200-015SFEF

2.2 3 X200-022SFEF

AWG10 / 5.3mm

2

0.2 1/4 X200-002NFU

0.4 1/2 X200-004NFU

0.75 1 X200-007NFU

AWG14 / 2.1mm

2

1.5 2 X200-015NFU

2.2 3 X200-022NFU

AWG10 / 5.3mm

2

3.7 5 X200-037LFU AWG12 / 3.3mm

2

No fuse required

0.4 1/2 X200-004HFEF/HFU 3A

0.75 1 X200-007HFEF/HFU 6A

1.5 2 X200-015HFEF/HFU

AWG16 / 1.3mm

2

2.2 3 X200-022HFEF/HFU

10A

3.0 4 X200-030HFEF

4.0 5 X200-040HFEF/HFU

AWG14 / 2.1mm

2

(60°C only)

15A

18 to 28 AWG /

0.14 to 0.75 mm

2

shielded wire

(see Note 4)

Note 1: Field wiring must be made by a UL-Listed and CSA-certified closed-loop

terminal connector sized for the wire gauge involved. Connector must be fixed

by using the crimping tool specified by the connector manufacturer.

Note 2: Be sure to consider the capacity of the circuit breaker to be used.

Note 3: Be sure to use a larger wire gauge if power line length exceeds 66ft. (20m).

Note 4: Use 18 AWG / 0.75mm

2

wire for the alarm signal wire ([AL0], [AL1], [AL2]

terminals).

Inverter Mounting

and installation

2

−

19