Section 8: Adjustment Procedures

M84Pro Service Manual PN 9001111A Page 8-6

7 Ensure screw (5) is secure on the left side of guide plate (4).

8 Test cycle and readjust as necessary.

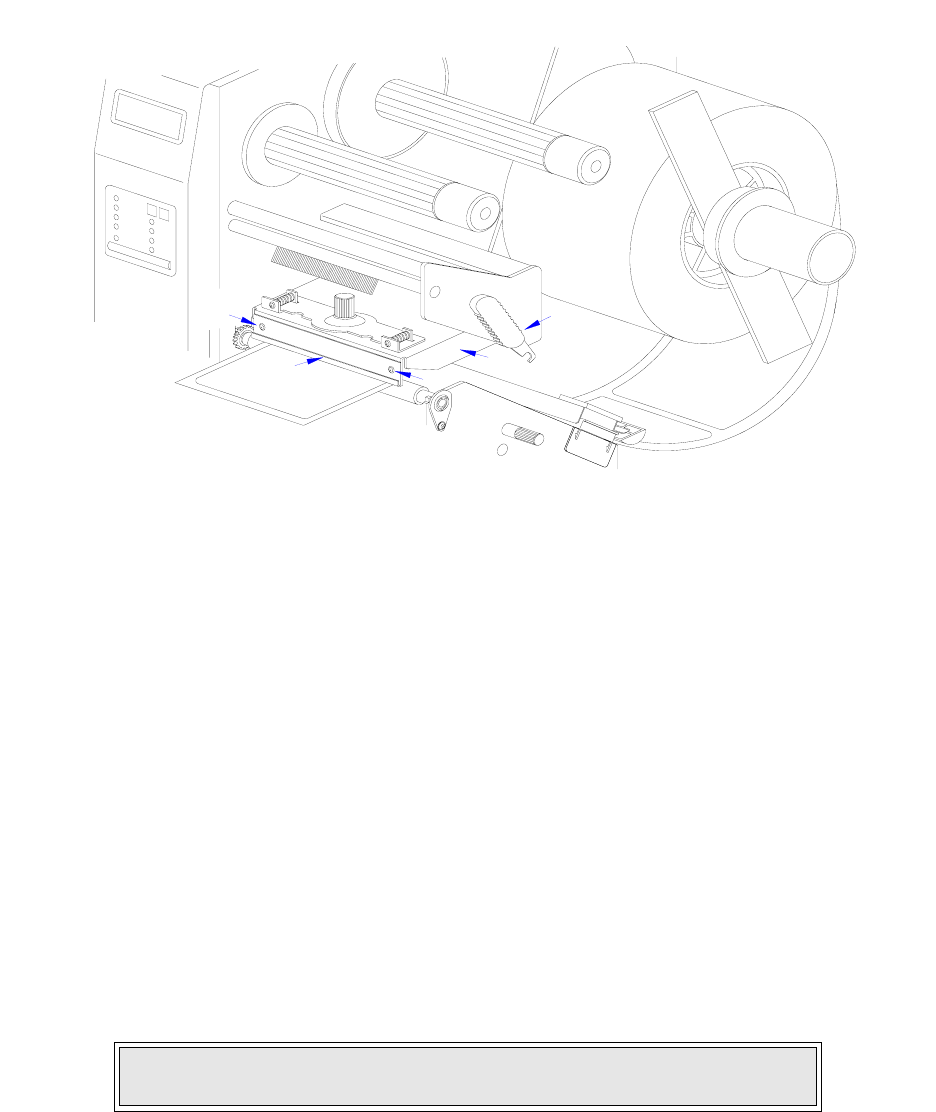

Figure 8-4, Ribbon Guide Plate Adjustment

FEED ROLLER ADJUSTMENT

Feed roller adjustment is used for fine tuning label tracking. By adjusting the pressure between

the upper and lower rollers, the media may be directed through the printer as desired. If mal-

adjusted, the label media will have a tendency to want to track to the left or to right depending on

which side has the greatest pressure.

A properly adjusted upper and lower feed roller assembly will have evenly applied pressure to

each side and be properly aligned. The pressure difference between each side should be 100

grams or less. A tension gauge will be required to measure the tension.

To acquire the desired adjustment; the upper, the lower, or both feed rollers may require

manipulation. Each roller may be adjusted along opposing X and Y axis. Different variations may

be required until the correct adjustment is achieved.

1 Switch the printer off and disconnect the power supply cord.

2 Open the top and right side housing covers.

3 Remove label stock from the printer and leave print head open.

4 Attach a strip of 20mm + wide liner backing paper to the end of the tension gauge.

NOTE: Figures 10-1, 10-2, and 10-3 of the Diagrams & Schematics section

provides guidance on housing cover, media, and ribbon removal.

M

E

D

I

A

M

E

D

I

A

2

1

5

4

3