Section 6: Troubleshooting

M84Pro Service Manual PN 9001111A Page 6-4

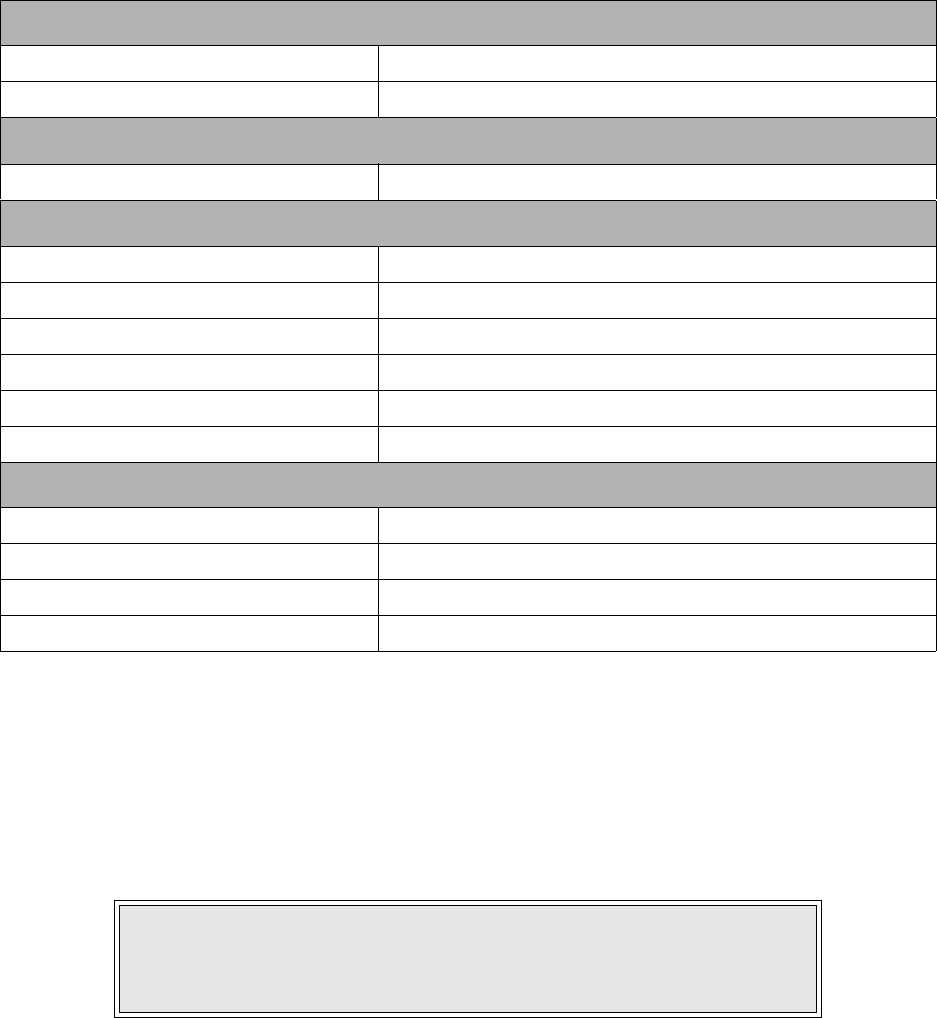

TROUBLESHOOTING PROCEDURES

The procedures below provide in depth instructions on symptom analysis of specific

components. If it is suspected that the problem lies within one of these components, refer to the

relative instructions.

RS232 S

ERIAL INTERFACE

• Ensure the serial cable is thoroughly connected to the PC and the printer.

• Ensure the serial cable is not defective. The minimum requirements is that a Null Modem

Cable or correct Pin Outs be used and that it be manufactured to specifications. Refer to the

Interface Specifications section of this manual.

• Ensure the RS232 Interface Module is installed. Different module types will have an impact

on transmission speed.

• Ensure the data stream is correct, all letters of command codes are in upper case, and with-

out spaces. Carriage Returns are also not acceptable in line fields.

Main power fuse defective. Replace fuse.

Defective power supply. Test with meter and replace as required.

ERROR LED ILLUMINATED

Print head not latched into position. Ensure print head assembly is latched.

LABEL LED IS ILLUMINATED

Label supply roll is empty. Replenish label supply.

Label stock is not routed through sensor. Ensure label roll is correctly installed.

Label sensor incorrectly positioned. Adjust sensor position.

Label sensor is blocked. Clean label sensor.

Incorrect label sensor threshold setting. Adjust label sensor threshold.

Platen drive malfunction. Perform drive train analysis.

RIBBON LED ILLUMINATED

Ribbon supply roll is empty. Replenish ribbon supply.

Ribbon supply is misaligned. Realign ribbon sensor.

Ribbon sensor is blocked. Clean ribbon sensor.

Ribbon rewind is without core. Install cardboard core.

CAUTION: NEVER CONNECT OR DISCONNECT INTERFACE CABLES

(OR USE A SWITCH BOX) WITH POWER APPLIED TO EITHER THE

PRINTER OR THE HOST. THIS MAY CAUSE DAMAGE TO THE INTER-

FACE CIRCUITRY AND IS NOT COVERED BY WARRANTY.

POWER LED NOT ILLUMINATED