H9 ASD Installation and Operation Manual 265

Cable/Terminal/Torque Specifications

Installation should conform to the 2005 National Electrical Code Article 110 (NEC) (Requirements for Electrical

Installations), all regulations of the Occupational Safety and Health Administration, and any other

applicable national, regional, or industry codes and standards.

Note: The following ratings are guidelines and shall not be the sole determining factor of the

lug or wire size used with the H9 ASD. Application-specific applicables, wire insulation

type, conductor material, and local and regional regulations are but a few of the

considerations when selecting the actual lug and wire type to be used with the H9 ASD.

Note: Cable/Terminal specifications are based on the rated current of the H9 ASD and Do

Not include the 10% Service Factor.

Note: Use only 75° C copper wire/cable for motor and power connections.

For further installation information see the section titled Installation and Connections on pg. 14.

Note: (*) Indicates that the item is one of a set of two parallel cables.

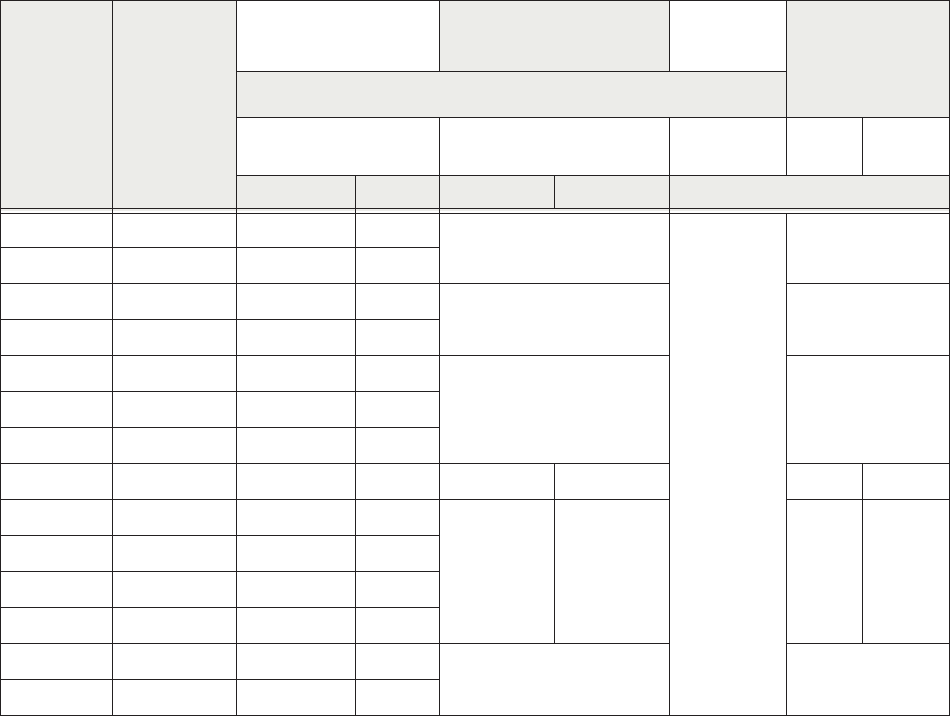

Table 20. 230-Volt H9 ASD Cable/Terminal/Torque Specifications.

Model

Number

VT130H9U

MCP Rating

(Amps)

Wire/Cable Size Lug Size Range

Terminal

Board

Torque

AWG or kcmil

Input/Output Power

Wire-Size/Lug-Capacity for

Input/Output Power

TB1 – 4

Terminals

3Ø-Input 3Ø-Output

Recommended Maximum 3Ø-Input 3Ø-Output In-Lbs./Nm

2035 30 14 10

14 to 8

20

(3-core shield)

5.3/0.6

11.5/1.3

2055 30 10 10

2080 50 8 8

12 to 8 17.7/2.0

2110 50 8 8

2160 75 6 3

8 to 3 21/2.42220 100 4 3

2270 125 3 3

2330 150 2 2 12 to 1/0 4 to 1/0 50/5.7 53/6

2400 175 1/0 4/0

6 to 250 2 to 300 275/31 168/19

2500 200 2/0 4/0

2600 250 3/0 4/0

2750 300 4/0 4/0

210K 400 *3/0 *1/0

6 to 250 275/31

212K 500 *250 *250