GENERAL DESCRIPTION

Rev. B

1-

1

5

1.2.12.3 Continuous Forms with Labels

Table 1-7. Continuous Forms with Labels

Front Entry Rear Entry

Minimum Maximum Minimum Maximum

Label Size Refer to Section 1.2.12.2. -

Width (inch)

(mm)

4.0

101

16.0

406

--

Length (inch)

(mm)

4.0

101

17.0

431

--

Weight

(not multi-part)

(g/m

2

)

(lb)

52.6

14

82.7

22

--

Weight

(one sheet of multi-part)

(g/m

2

)

(lb)

41.4

11

56.4

15

Label Thickness (inch)

(mm)

0.0

0.0

0.0047

0.12

Total Thickness (inch)

(mm)

0.0025

0.065

0.021

0.53

--

Quality (Multi-part forms) Plain paper, reclaimed paper, carbonless

multi-part forms

Quality (Label) AVERY CONTINUOUS FORM LABELS,

AVERY MNI-LINE LABELS, or the same

quality labels

Multi-part binding

• Rough bindings of multi-part paper cause paper jam.

• The each sheet of multi-part paper should normally be put

together by spot-gluing, paper-stapling, tape stitching. Spot-gluing

is recommended for the better printing quality.

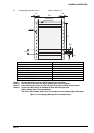

• Spot-gluing must be applied on both sides of paper (Refer to

Figure 1-7.).

• The spot-glued parts must be pressed flat. There must be no

creases in the paper.

• The paper-stapling must be applied from the front of paper and the

paper must be flat (Refer to Figure 1-8.).

• Paper-stapling must be applied for both feeding directions (Refer

to Figure 1-9.).

• The paper-stapling should be flat (Refer to Figure 1-10.).

• Never use metal staples.

• The position of binding must be outside of printable area.

• Multi-part paper should be bound firmly to each other and the

binding must not be too large.

Perforation Refer to Section 1.2.12.5.

Notes

• The easy-cone-off label should not be used.

• Every label must be put on the carrier.

• Each comer of those labels must be rounded.

• Each label and backing sheet should not have any folds or

creases.

• Between each label, there should be the same sheet as those

labels.

• The backing sheet must be continuous paper.

• Continuous forms with labels should be inserted from front

entrance.

Refer to Section 1.2.12.6.