DFX-8500

Rev. B

1-16

1.2.12.4 Overlapping Multi-part Form

Table 1-8. Overlapping Multi-part Form

Front Entry Rear Entry

Minimum Maximum Minimum Maximum

Width (inch)

(mm)

4.0

101

16.0

406

--

Length (inch)

(mm)

4.0

101

17.0

431

--

Weight

(not multi-part)

(g/m

2

)

(lb)

52.6

14

82.7

22

--

Weight

(one sheet of multi-part)

(g/m

2

)

(lb)

41.4

11

56.4

15

--

Copies 1 original + 5 copies + 1 backing

sheet

-

Total Thickness

(print area)

(inch)

(mm)

0.0025

0.065

0.021

0.53

--

Total Thickness

(overlap area)

(inch)

(mm)

0.005

0.13

0.028

0.70

--

Overlapping Length (inch)

(mm)

more than 0

more than 0

0.39

10

--

Quality (multi-part forms) Plain paper, reclaimed paper,

carbonless multi-part forms

-

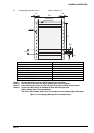

Multi-part binding

• Multi-part paper must be bound at the top side by spot-gluing (Figure 1-

12.).

• The bindings must not be too hard. And there should not be any spilt

glue.

• The position of binding must be outside of printable area.

• Multi-part paper should be bound firmly to each other and the binding

must not be too large.

Perforation Refer to Section 1.2.12.5.

Notes

• Overlapping multi-part form should be inserted from front entrance.

Refer to Section 1.2.12.6.

1.2.12.5 Perforation

• Weak horizontal and vertical perforations cause paper jams.D

• The length ratio of the cut part and uncut part of perforations must be more than 3 to 1 and less than 5

to 1 (Refer to Figure 1-13.).

• Horizontal perforations must have an uncut part in each end of the paper (Refer to Figure 1-14.).

• At the intersection of horizontal and vertical perforations, the cut part of the perforations must not cross

each other (Refer to Figure 1-15.).

• The raised part at the perforation must be less than 1 mm when the bottom layer kept by force (Refer

to Figure 1-16.).

1.2.12.6 Notes

• Clean paper (with no folds, creases, tears) should be used (Refer to Figure 1-17.).

• The sprocket hole must be circular. The hole may have teeth (Refer to Figure 1-18.).

• The sprocket hole of each layer must not be shifted (Refer to Figure 1-19.).

• The litter of sprocket holes must be removed from the paper.

• Paper should be fan-folded at horizontal perforations. Never use one that is not fan-folded property

(Refer to Figure 1-20.).

• No hole is acceptable in the printable area.

• Paper must be torn off accurately along perforations.