RESTRICTED USE ONLY Fargo Electronics, Inc.

HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

16

Functional Specifications

The Card Printer utilizes two different, yet closely related printing technologies to achieve its

remarkable direct-to-card print quality for dye-sublimation and resin thermal transfer. The

Card Printer will print from any IBM-PC® or compatible running Windows® 98Se/Me,

Windows NT 4.0, Windows 2000 or Windows XP Pro.

The following describes how each of these technologies works:

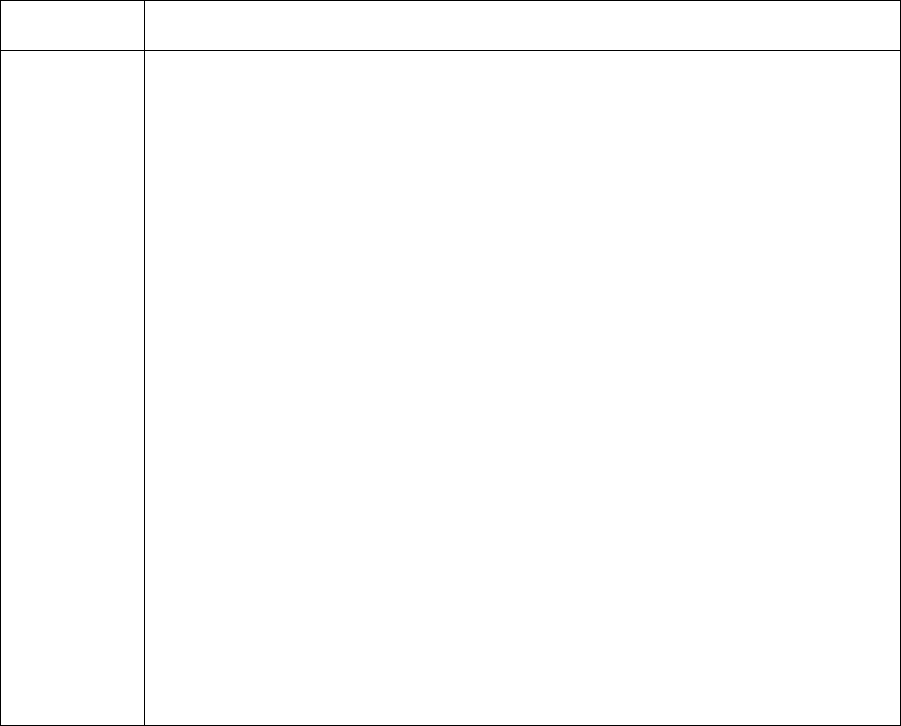

Function Description

Dye-

Sublimation

Dye-Sublimation is the print method the Card Printer uses to produce

smooth, continuous-tone images that look photographic. (Note: This

process uses a dye-based ribbon roll that is partitioned by a number of

consecutive color Panels.)

• Process colors: The Panels are grouped in a repeating Series of

three process colors - yellow, magenta and cyan (YMC), along the

entire length of the Print Ribbon.

• Panels: The Printer always prints the yellow Panel first, followed by

the magenta Panel and the cyan Panel.

• Printhead: As the Print Ribbon passes beneath the Printhead,

hundreds of thermal elements within the Printhead heat the dyes on the

ribbon. (Note: When these dyes are heated, they vaporize and diffuse

into the surface of the card. A separate pass is made for each of the

three color Panels on the ribbon.)

• color Shades: By combining the colors of each Panel and by varying

the heat used to transfer these colors, it is possible to print up to 16.7

million different shades of color. (Note: This blends one color smoothly

into the next, producing photo-quality images with absolutely no dot

pattern.)

• Dye-Diffusion Thermal Transfer: It is the process of heating a dye

suspended in a cellulous substrate until the dye can flow, diffusing into

the dye receptive surface of the card or InTM. This produces the image

in the surface of the card.

Continued on the next page