147

3

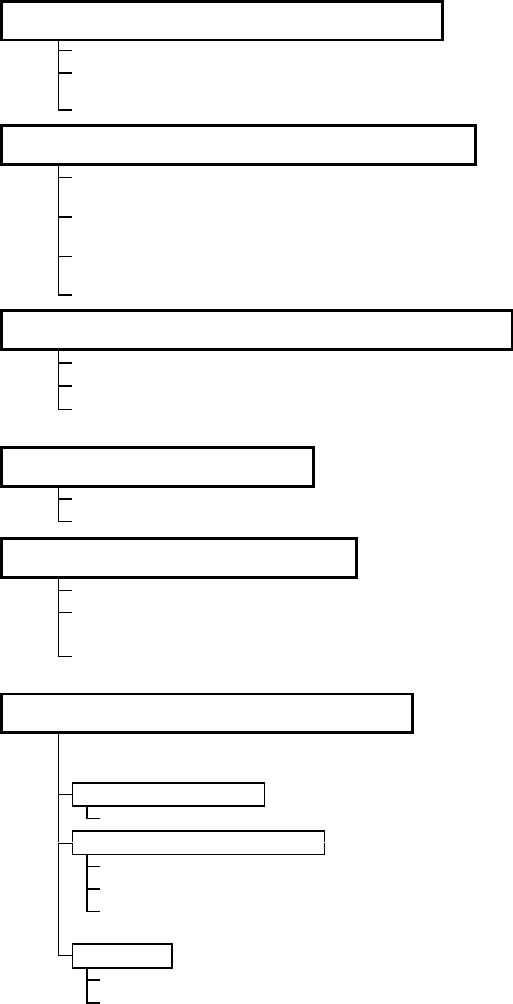

.2.2 Motor rotates in opposite direction

Check that the phase sequence of output terminals U, V and W is correct.

Check that the start signals (forward rotation, reverse rotation) are

connected properly.

Check the setting of Pr. 17 "RUN key rotation direction selection".

3

.2.3 Speed greatly differs from the setting

Check that the frequency setting signal is correct. (Measure the input signal

level.)

Check that the following parameter settings are correct (Pr. 1, Pr. 2,

Pr. 19, Pr. 38, Pr. 39, Pr. 95, C2 to C7).

Check that the input signal lines are not affected by external noise. (Use

shielded cables)

Check that the load is not too heavy.

3

.2.4 Acceleration/deceleration is not smooth

Check that the acceleration and deceleration time settings are not too short.

Check that the load is not too heavy.

Check that the torque boost setting is not too large to activate the stall

prevention function.

3

.2.5 Motor current is large

Check that the load is not too heavy.

Check that the torque boost setting is not too large.

3

.2.6 Speed does not increase

Check that the maximum frequency setting is correct.

Check that the load is not too heavy. (In agitators, etc., load may become

heavier in winter.)

Check that the torque boost setting is not too large to activate the stall

prevention function.

3

.2.7 Speed varies during operation

When slip compensation is selected, the output frequency varies with load

fluctuation between 0 and 2Hz. This is a normal operation and is not a fault.

1) Inspection of load

Check that the load is not varying.

2) Inspection of input signal

Check that the frequency setting signal is not varying.

Check that the frequency setting signal is not affected by noise.

Check for a malfunction due to an undesirable current when the transistor

output unit is connected. (Refer to page 25)

3) Others

Check that the wiring is within specified length.

Check that the inverter is either FR-S540-1.5K, 2.2K or 3.7K and GD

2

load is samll (at the mnitor GD

2

or smaller)

If so, set the Pr. 72 "PWM frequency selection" to 6kHz or higher. When setting

the PWM to a higher frequency, check for noise or leakage current problem and

take countermeasures against it.