64

2

.3.6 Electronic overcurrent protection

Set the current of the electronic overcurrent protection to protect the motor from

overheat. This feature provides the optimum protective characteristics, including

reduced motor cooling capability, at low speed.

Parameter Name Factory Setting Setting Range

9 Electronic thermal O/L relay Rated output current * 0 to 50A

* 0.1K to 0.75K are set to 85% of the rated inverter current.

<Setting>

Set the rated current [A] of the motor.

(Normally set the rated current at 50Hz if the motor has both 50Hz and 60Hz rated

current.)

Setting "0" in Pr. 9 disables electronic thermal O/L relay (motor protective function).

(The protective function of the inverter is activated.)

When using a Mitsubishi constant-torque motor, first set "1" in Pr. 71 "applied motor"

to choose the 100% continuous torque characteristic in the low-speed range. Then,

set the rated motor current in Pr. 9 "electronic thermal O/L relay".

CAUTION

• When two or more motors are connected to the inverter, they cannot be protected

by the electronic overcurrent protection. Install an external thermal relay to each

motor.

• When the difference between the inverter and motor capacities is large and the

setting is small, the protective characteristics of the electronic overcurrent

protection will be deteriorated. In this case, use an external thermal relay.

• A special motor cannot be protected by the electronic overcurrent protection.

Use an external thermal relay.

♦

♦♦

♦

Related parameters

♦

♦♦

♦

When constant-torque motor is used

⇒

Pr. 71 "applied motor" (refer to page 93)

2

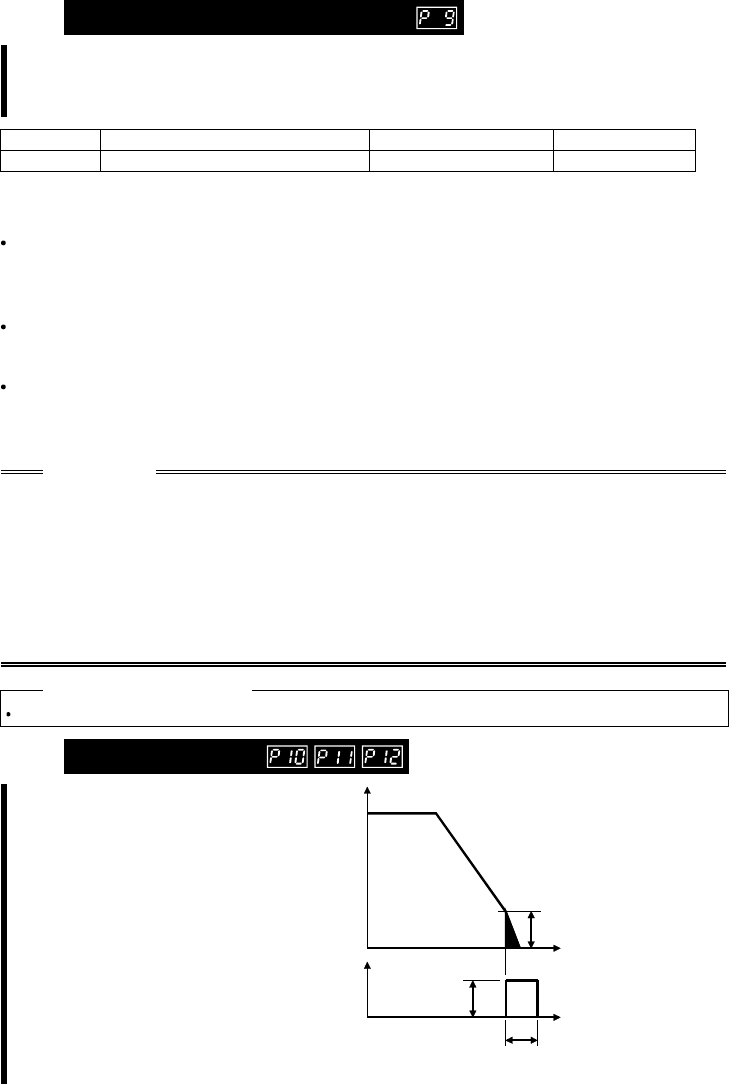

.3.7 DC injection brake

By setting the DC

injection brake voltage

(torque), operation time

and operation starting

frequency, the stopping

accuracy of positioning

operation, etc. or the

timing of operating the

DC injection brake to

stop the motor can be

adjusted according to the

load.

Output frequency (Hz)

Time

Time

DC injection

brake voltage

"Operation

frequency"

Pr.10

Pr.12

"Operation

voltage"

Pr.11 "Operation time"