276

CHAPTER 5 SETTINGS AND THE PROCEDURE

BEFORE OPERATION

This chapter describes the procedure prior to the Q64TCN operation, the name and setting of each part of the

Q64TCN, and wiring method.

5.1 Handling Precautions

This section describes the precautions for handling the Q64TCN.

• Do not drop the module case, or do not subject it to strong impact.

• Do not remove the printed-circuit board from the case. Doing so can cause module failure.

• Tighten the screws such as a module fixing screw within the following torque ranges.

Undertightening the screws can cause short circuit, failure, or malfunction.

*1 The module can be easily fixed onto the base unit using the hook at the top of the module.

However, it is recommended to secure the module with the module fixing screw if the module is subject to significant

vibration.

• The following table shows the applicable solderless terminal installed to the terminal block. For wiring, use

the cable applicable to the following wire and mount with the applicable tightening torque. Use a UL-

approved solderless terminal and tools recommended by the manufacturer of the solderless terminal. The

sleeve solderless terminal cannot be used.

• To mount the module, while pressing the module mounting lever located in the lower part of the module, fully

insert the module fixing projection into the hole in the base unit and press the module until it snaps into

place. Incorrect mounting may cause malfunction, failure or drop of the module.

Securely fix the module with screws if it is subject to vibration during use.

• For the mounting direction of the module, the mounting surface, the combination with other devices, and the

distance from other devices, refer to the following.

QCPU User's Manual (Hardware Design, Maintenance and Inspection)

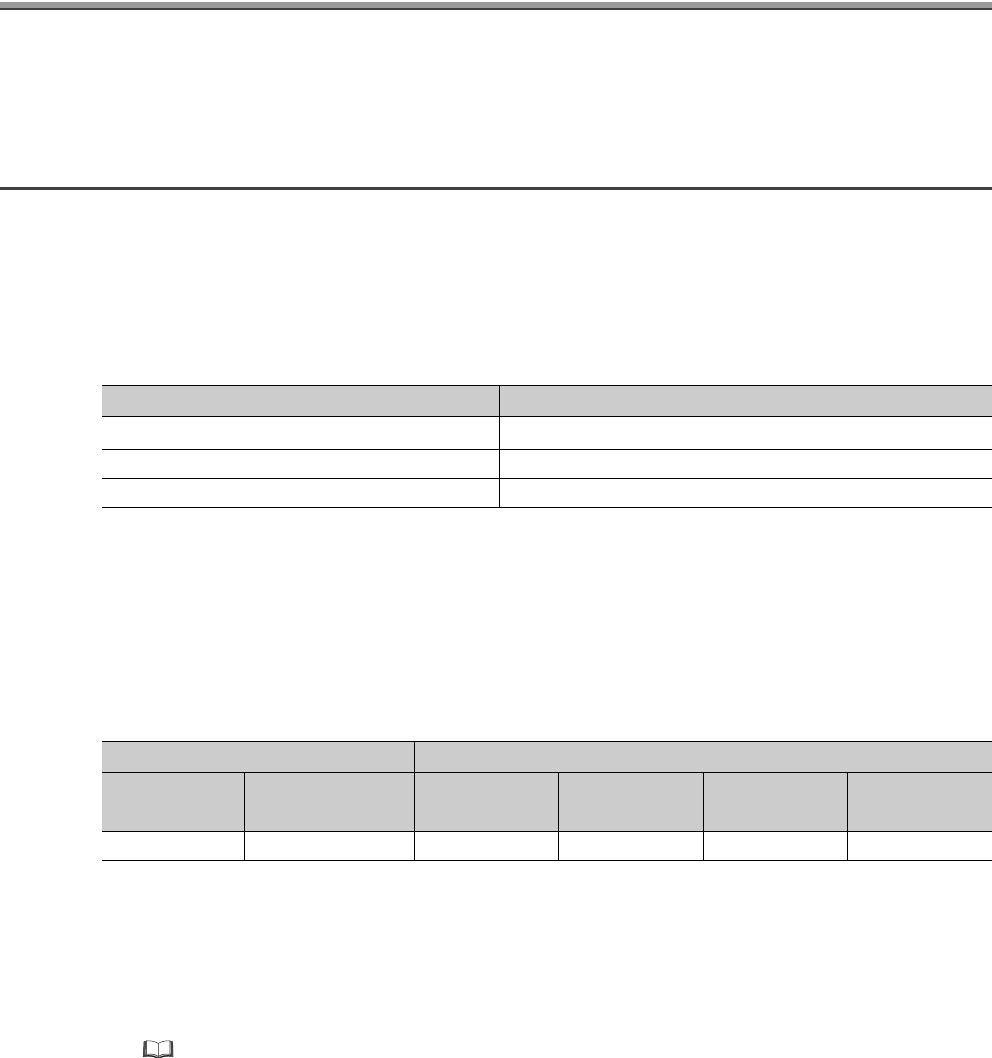

Screw Tightening torque range

Module fixing screw (M3 screw)

*1

0.36 to 0.48N • m

Terminal screw (M3 screw) 0.42 to 0.58N • m

Terminal block mounting screw (M3.5 screw) 0.66 to 0.89N • m

Solderless terminal Wire

Model name

Applicable

tightening torque

Wire diameter Type Material

Temperature

rating

R1.25-3 0.42 to 0.58N • m 22 to 18 AWG Stranded wire Copper wire 75°C or more