Disassembly, Reassembly and Lubrication

CL-S6621 3-50

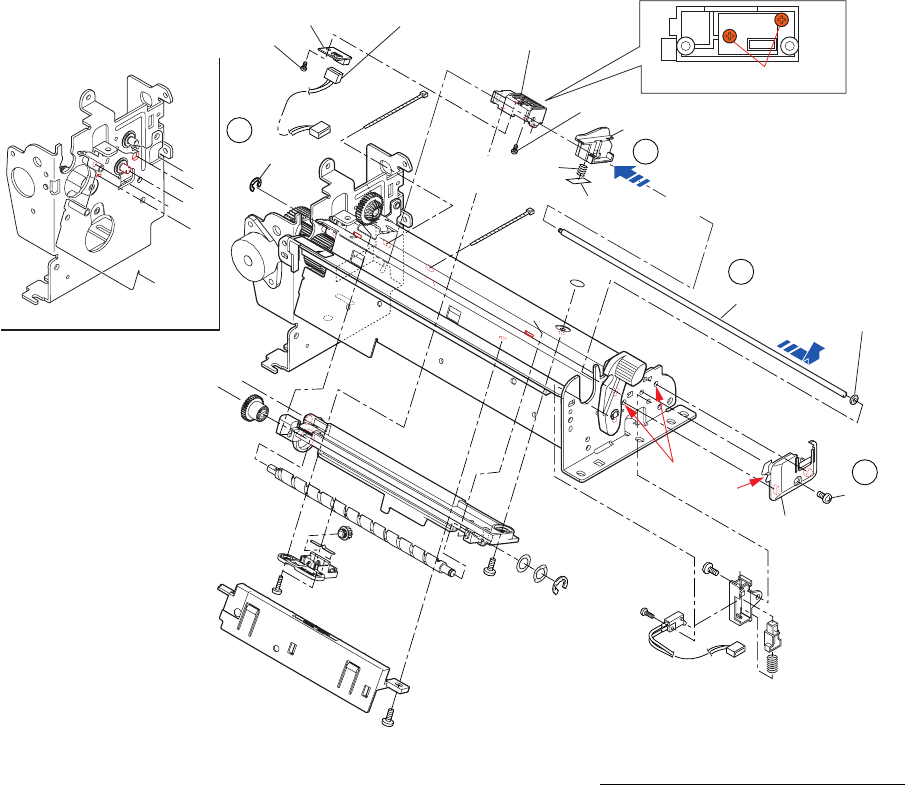

Shaft Sensor Guide

Holder Adjust Sensor L

Guide Paper R

SA Ref Sen PCB

No.0 PHT (BT#1) M2x3

No.0 PHT (BT#1) M2x3

SA, Ref Sensor Cable

Spring Friction

Sen PG

Plate Function PG

b

b

c

c

a

a

d

BH, M3x4 (NI)

Spacer Guide Shaft

Holder, Guide Sensor L

E-ring, 1.5

a

[Bottom View]

No.0 PHT (BT#1) M2x3

8

9

A

B

10

7

(2) SA Ref Sen PCB

1. Remove the “Carriage Adjust Sensor L”. Perform steps 1 to 7)-2 in above “3-6-20(1)

“Carriage Adjust Sensor L” and “SA, Head Up Switch””.

2. Disengage the “E-Ring, 1.5” (), remove 1 screw (BH, M3x4 (NI)) (), and detach the

“Holder, Guide Sensor L”.

3. Slide the “Guide Paper R” () to the left and remove the “Shaft Sensor Guide” () in the

direction shown by the arrow, together with the “Guide Paper R” Block and “Holder Adjust

Sensor L” Block.

4. Remove the “Spacer Guide Shaft”, and then pull out the “Guide Paper R” Block and “Holder

Adjust Sensor L” Block from the “Shaft Sensor Guide”.

5. Remove the “Spring Friction Sen PG” and the “Plate Friction PG” from the “Guide Paper R”.

6. Disconnect the “SA, Ref Sensor Cable” from the “SA Ref Sen PCB”.

7. Remove the 2 screws (No.0 PHT (BT#1) M2x3) and detach the “SA Ref Sen PCB” from the

“Holder Adjust Sensor L”.

Notes on reassembling:

• When the “SA Ref Sen PCB” is replaced with new one, perform the sensor adjustment.

Refer to “

3-7-1 Transparent/Reflective Sensor Position Adjustment”.

• Assemble the “Shaft Sensor Guide” () (with the “Holder Adjust Sensor L” Block, “Guide,

Paper R” Block and the “Spacer Guide Shaft”), and align its ends in places. Next, assemble

the “Holder, Guide Sensor L”. (Its groove “A” should engage with the frame plate. Also its

protrusions should be inserted into the holes “B” in the frame.)

(to be continued on the next page)