Operation of Each Mechanism

CL-S6621 2-14

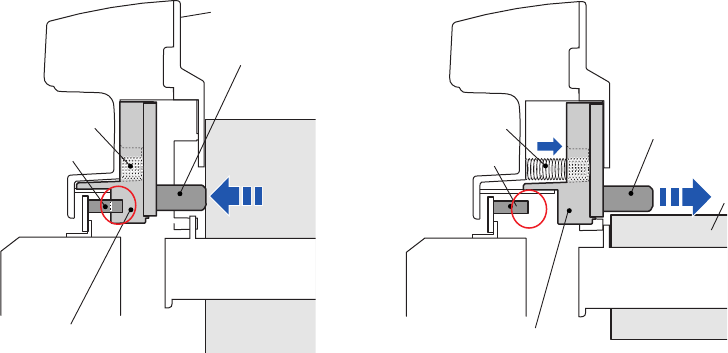

2-1-6. Paper Near End Detection Mechanism

The component of the Paper near end detection mechanism is as follows:

(a) SA PNE Sensor (A part of the main body)

(b) Lever PNE (A part of the “Roll Paper Holder”)

(c) Slider PNE (A part of the “Roll Paper Holder”)

(d) Spring PNE (A part of the “Roll Paper Holder”)

The paper near end sensor is used to detect a paper near end status of roll paper installed in the

printer.

The knob of the “Lever PNE” is pushed by the side of roll paper and the “Slider PNE” engages with

the “SA PNE Sensor” (fixed part on the main body). In this state, the “SA PNE Sensor”

(photointerrupter) turns OFF.

When printing proceeds and the diameter of roll paper is reduced to the preset paper near end

point, the knob of the “Lever PNE” that was pushed by the roll paper pops up, and the “Slider PNE”

comes off the “SA PNE Sensor”. In this state, the “SA PNE Sensor” (photointerrupter) turns ON.

The CPU on the Main PCB detects the ON/OFF status of the “SA PNE Sensor” (photointerrupter)

and judges if the roll paper reaches the near end status.

The paper near end position can be changed mechanically by sliding the knob of the “Lever PNE”

up or down.

Lever PNE

Spring PNE

SA PNE Sensor

Slider PNE

Roll Paper

Roll Paper Holder

[Normal Status]

Lever PNE

Spring PNE

SA PNE Sensor

Slider PNE

Roll Paper

[PNE (Paper Near End) Status]