Operation of Each Mechanism

CL-S6621 2-10

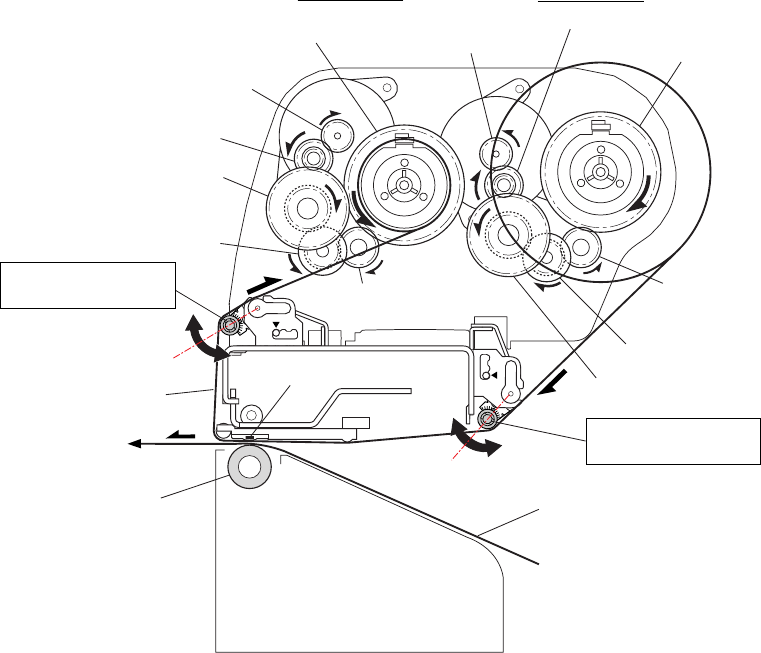

SA2_Platen

Media

Ribbon

Thermal Head

SA, Ribbon Tension

Shaft F

SA, Ribbon Tension

Shaft R

Take-up Side

Supply Side

Gear Ribbon Shaft R

Gear Ribbon Shaft F

SA Ribbon Motor R

SA Ribbon Motor F

Gear Reduction Ribbon 1

Gear Reduction Ribbon 1

Gear Reduction Ribbon 2

Gear Reduction Ribbon 2

Gear Reduction Ribbon 3

Gear Reduction Ribbon 3

Gear Idle Ribbon

Gear Idle Ribbon

[Front]

2-1-4. Printing and Ribbon Feed Mechanism

The major components of the printing and ribbon feed mechanism are:

(a) SA, Head (d) SA, Ribbon Tension Shaft F/R

(b) SA Ribbon Motor F/R (e) SA, Ribbon Sensor (Front/Rear)

(c) Ribbon gear train

Ink ribbon is set to the printer using the ribbon holders. Ribbon is supplied from the supply reel and

is taken up by the take-up reel with adequate ribbon tension, via the “SA, Ribbon Tension Shaft R”

and “SA, Ribbon Tension Shaft F”. The “SA, Ribbon Tension Shaft F/R” is always pushed outward

by the internal springs, and, when ribbon slacks, it moves outward. When ribbon tightens, it moves

inward. (Refer to the figures on the later pages.)

The same ribbon sensor is installed on the front and rear sides. The ribbon sensor on the front side

is used to detect the position of the “SA, Ribbon Tension Shaft F” (i.e., the ribbon tension on the

front side). While, the ribbon sensor on the rear side is used to detect the position of the “SA,

Ribbon Tension Shaft R” (i.e., the ribbon tension on the rear side).

The ribbon sensor on the front side is also used to detect a ribbon running condition, and that on

the rear side is used to detect the ribbon end.

On the front side, the “SA Ribbon Motor F” turns to take up ribbon. On the rear side, the “SA

Ribbon Motor R” turns to supply ribbon, while applying adequate back tension to ribbon to

eliminate ribbon slack.

Printing:

When printing with ink ribbon, ink on the ribbon is melted by the heated thermal element of the “SA,

Head” and is transferred on the media surface.