Operation of Each Mechanism

CL-S6621 2-12

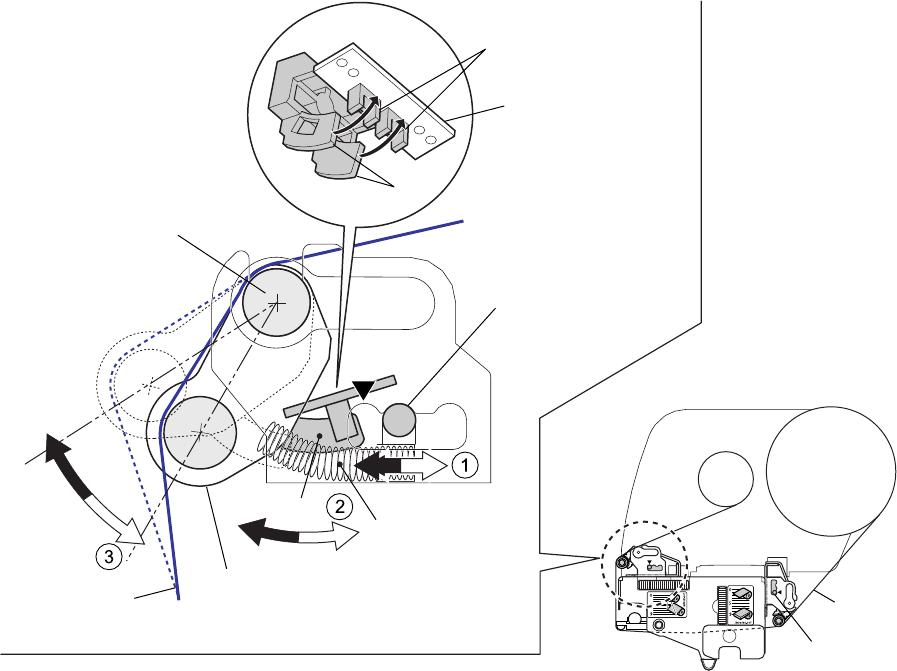

Detecting Ribbon Tension (Ribbon Sensors):

The same ribbon sensor is installed on the front and rear sides. Since the operation is the same on

both sides, the front side operation is explained here:

When ribbon is taken up, the ribbon tightens and the “SA, Ribbon Tension Shaft F” is pushed

inward (in the direction of “a”) by the ribbon. At this time, the claws “A” attached to the “SA, Ribbon

Tension Shaft F” are inserted into the photointerrupters of the “SA, Ribbon Sensor”, and the

photointerrupters turn OFF.

During printing, the ribbon is fed forward together with media and the ribbon will slack. This, the

“SA, Ribbon Tension Shaft F” is moved outward (in the direction of “b”) by the spring (“B”) force,

and the claws “A” come off the photointerrupters. So, the photointerrupters turn ON and the “SA

Ribbon Motor F” turns faster to take up the ribbon quickly. Then, the claws “A” are inserted into the

photointerrupters again, and the “SA Ribbon Motor F” resumes normal speed.

This cycle is repeated and constant tension is applied to the ribbon.

(The two claws “A” are arranged so that they are inserted into or released from the

photointerrupters with a slightly different timing. This function enables to finely control the ribbon

tension.)

On the rear side, during printing, ribbon will be tightened. If it is tightened, the ribbon sensor turns

ON and the “SA Ribbon Motor R” turns faster than normal speed to quickly supply ribbon.

Tension Adjustment Mechanism:

To apply adequate ribbon tension, you can change the spring “B” force as follows:

The spring force is adjustable in 3 steps with the “Tension Adjustment Knob (Front/Rear)”. As you

move the knob toward the

T mark, the spring force becomes stronger since the spring “B” is

moved to the left in the above figure.

Tension Adjustment

Knob (Front)

SA, Ribbon Sensor

Supporting Point

SA, Ribbon

Tension Shaft F

Ribbon

Spring Ribbon

Tension (2 pcs.)

Ribbon

A

Tension Adjustment

Knob (Rear)

[Right side view]

a

b

B

Ribbon Sensor

A