Operation of Control Parts

CL-S6621 2-26

(SA, Ribbon Sensor)

Ribbon Sensor1

2

3

1

PT501

PS501

R501

4

Front (Take-up side)

2

3

1

4

Rear (Supply side)

2

3

1

J104

4

(Same as above circuit)

PT501

2

3

1

J105

4

[SA, Ribbon PCB]

+3.3V

14

13

J102

U1A

CPU

34

PCM0

14

13

32

PCM2

J19

16

15

31

PCM3

16

15

29

PCM5

Ribbon Sensor2

PS502

R502

(SA, Ribbon Sensor)

+3.3V

1

1

+3.3V

+3.3V

SENS_A1

SENS_A2

SENS_B1

SENS_B2

C175

RIBSENS_A1

RA20

5

6

U21C

C176

C177

C178

R136

R137

R138

R139

9

8

U21D

11

10

U21E

13

12

U21F

RIBSENS_A2

RIBSENS_B1

RIBSENS_B2

U2A

U2B

U2C

U2D

2

3

5

6

9

8

12

11

[SA, Main PCB]

18-20 18-20

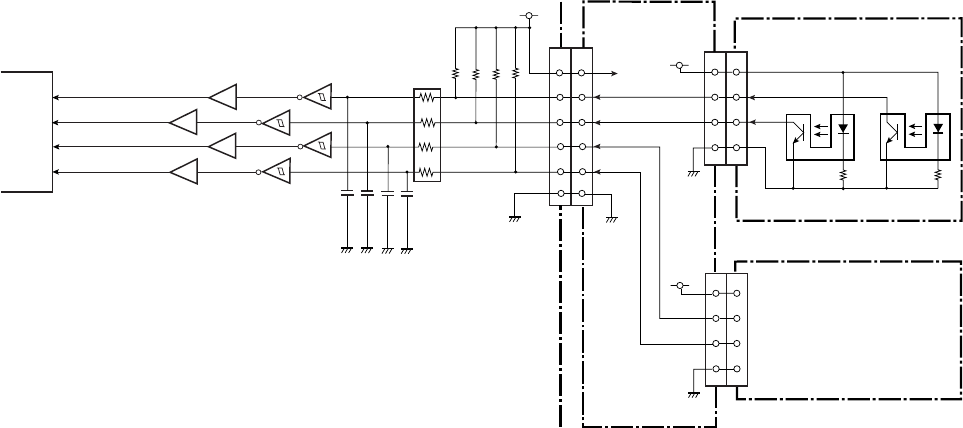

(3) Ribbon Sensor F/R

The ribbon sensor F (“SA, Ribbon Sensor” mounted on the front side) is used to detect the

ribbon tension on the front side as well as ribbon running. While, the ribbon sensor R (“SA,

Ribbon Sensor” mounted on the rear side) is used to detect the ribbon tension on the rear side

as well as the ribbon end. These sensors are photointerrupters.

Ribbon sensor F:

The ribbon sensor F is used to keep the ribbon tension on the front side constant. When

printing starts, ribbon is fed and then the front side ribbon slacks. Then, the claws of the “SA,

Ribbon Tension Shaft F” come off the photointerrupters on the “SA, Ribbon Sensor” and the

photointerrupters turn ON. Thus, pin 34/32 (RIBSENS_A1/A2) of U1A (CPU) goes "High" level.

In this case, U1A (CPU) increases the revolution speed of “SA Ribbon Motor F” to take up the

slack of ribbon. As a result, ribbon tightens and the claws are inserted into respective

photointerrupters. Thus, pin 34/32 (RIBSENS_A1/A2) of U1A (CPU) goes "Low" level. Then,

U1A (CPU) slows down the revolution speed of “SA Ribbon Motor F”. During printing, this cycle

is repeated and constant ribbon tension is maintained.

If ribbon is not correctly fed during printing, the ON/OFF state of the photointerrupters on the

“SA, Ribbon Sensor” becomes improper. Thus, the CPU can detect an abnormal ribbon feed.

Ribbon sensor R:

The ribbon sensor R is used to keep the ribbon tension on the rear side constant. When

printing starts, ribbon is fed and the rear side ribbon tightens. Then, the claws of the “SA,

Ribbon Tension Shaft R” are inserted into respective photointerrupters on the “SA, Ribbon

Sensor” and the photointerrupters turn OFF. Thus, pin 31/29 (RIBSENS_B1/B2) of U1A (CPU)

goes "Low" level. In this case, U1A (CPU) increases the revolution speed of “SA Ribbon Motor

R” to supply ribbon faster. As a result, ribbon slacks and the claw comes off the

photointerrupter. Thus, pin 31/29 (RIBSENS_B1/B2) of U1A (CPU) goes "High" level. Then,

U1A (CPU) slows down the revolution speed of the “SA Ribbon Motor R”. During printing, this

cycle is repeated and constant ribbon tension is maintained.

When ribbon runs out, the ON/OFF state of the photointerrupters on the “SA, Ribbon Sensor”

becomes unchangeable. Thus, the CPU can detect the ribbon end.