5-36

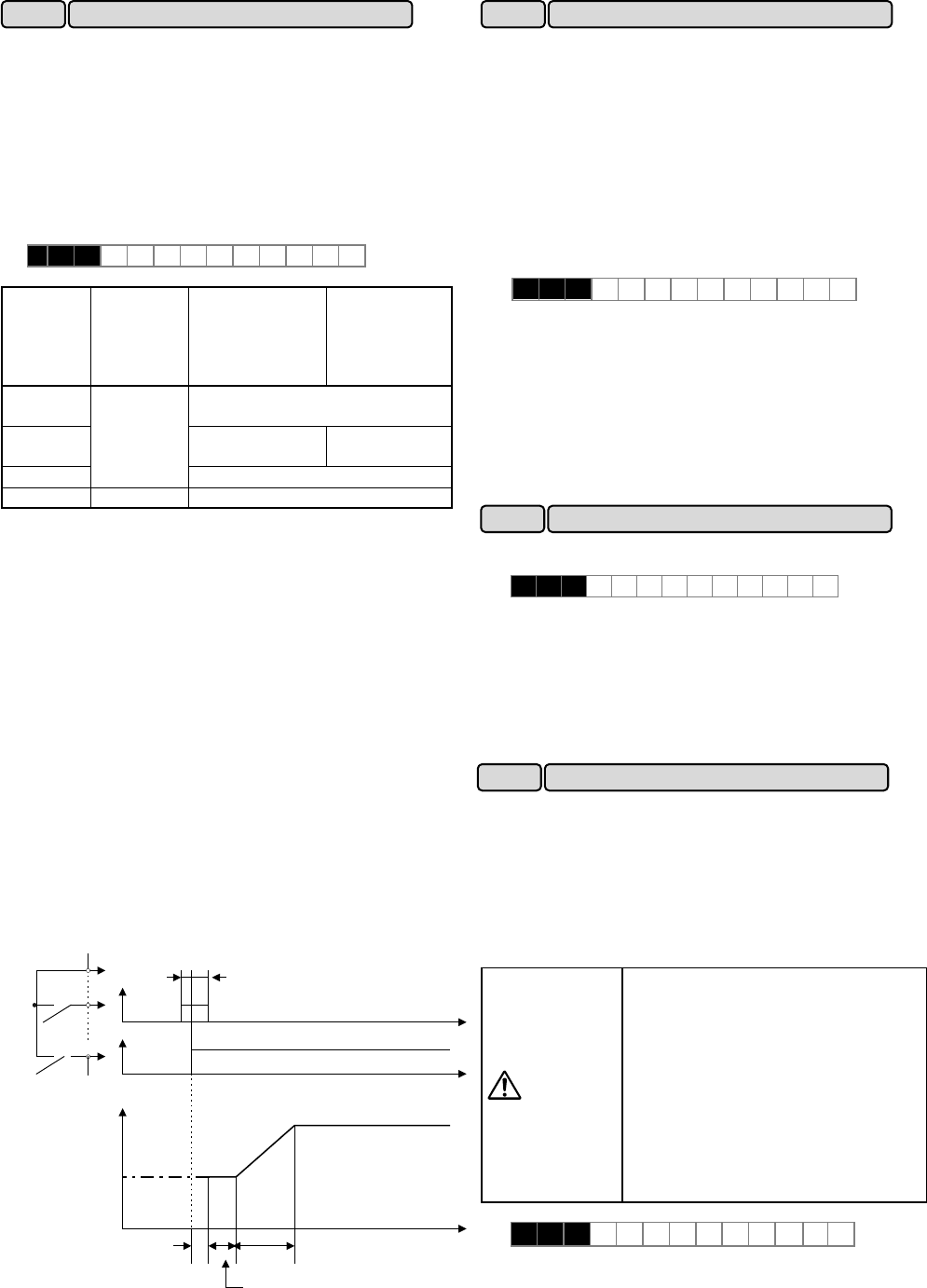

This function smoothly starts the motor which is coasting

after a momentary power failure or after the motor has

been subject to external force, without stopping motor.

At startup, this function detects the motor speed and

outputs the corresponding frequency, thereby enabling a

shock-free motor startup. Although the normal startup

method is used, when the coasting speed of the motor is

120 Hz or more as an inverter frequency, when the value

set to "F03 Maximum frequency," exceeds the value set to

"F15 Frequency limiter (upper limit)." and when the

coasting speed is less than 5 Hz as an inverter frequency.

H 0 9 S T A R T M O D E

Set value 0,1,2

Set value STM

Restart after a

momentary power

failure or

Line-to-inverter

switching

Other

operation

0

Inactive

(normal starting)

1

Active

(smoothly starting)

Inactive

2

OFF /

not selected

Active

any value ON Active

STM: Start characteristics selection signal(E01 to E09: 26)

NOTE:

-1: Automatically restart when overcurrent or overvoltage is

detected during smoothly starts.

-2: The coasting speed is used 100 Hz or less as an

inverter frequency.

-3: When H09:2 or STM:ON, it needs the time more than

normal start even the motor is STOP because the motor

speed is detected on ALL situation. And it may be

rotated the motor when the load is too small.

-4: Auto tuning(P04/A13: 2) should be done to use this

function.

-5: When the used motor slippage is too differ from FUJI

motor, the "Slip compensation control (P09, A18)"

should be set. The characteristics may not be satisfied.

When the operation above is to be problem, this function

is not used (inactive).

This function may not be satisfied the characteristics

because of the load condition, motor constant, operating

frequency, coasting speed, wire length, momentary

power failure time or external factor.

P24

STM

FWD

Time

0.1 s or

longer

0.2 s or

longer

ON

Time

Output

frequency

(motor speed)

Speed

search

In this section, the output

voltage is gradually increased

in steps to minimize shock.

Acceleration

ON

Note: The dotted-dashed line indicates motor speed.

When the output frequency is fixed (constant-speed

operation) at light loads and except for”0.0” is set to F09,

"Torque boost 1," this function automatically reduces the

output voltage, while minimizing the product (power) of

voltage and current.

Auto tuning(P04/A13: 2) should be done to use this

function.

The energy-saving operation does not be operated when

set below.

- Under Torque control

- Selected the Automatic torque boost

- Selected the Torque vector control

- Under PG vector control

Set value 0: Inactive

1: Active

Note:

-Use this function for square law reduction torque loads

(e.g., fans, pumps). When used for a constant-torque

load or rapidly changing load, this function causes a delay

in control response.

-The energy-saving operation automatically stops

during acceleration and deceleration and when the

torque limiting function is activated.

This function selects the inverter stopping method when

a stop command is entered.

H 1 1 DEC M O D E

Set value 0: Deceleration-to-stop based on data set to

"H07 Non-linear acceleration and

deceleration"

1: Coasting-to-stop

Note:

This function is effective only when a stop command is

entered and, therefore, is ineffective when the motor is

stopped by lowering the set frequency.

An overcurrent trip generally occurs when current flows

above the inverter protective level following a rapid

change in motor load. The instantaneous overcurrent

limiting function controls inverter output and prohibits the

flow of a current exceeding the protective level even

when the load changes.

As the operation level of the instantaneous overcurrent

limiting function cannot be adjusted, the torque limiting

function must be used.

WARNING

As motor generation torque may be

reduced when instantaneous

overcurrent limiting is applied, set this

function to be inactive for equipment

such as elevators, which are

adversely affected by reduced motor

generation torque, in which case an

overcurrent trip occurs when the

current flow exceeds the inverter

protective level. A mechanical brake

should be used to ensure safety.

as accident may result.

H 1 2 INST C L

Set value 0: Inactive

1: Active

H 1 0 E N E R G Y S A V

H12 Instantaneous overcurrent limiting

H10 Energy-saving operation

H11 DEC mode

H09 Start mode