Paper thickness lever Set the paper thickness lever to the appropriate position, as

indicated in the following table.

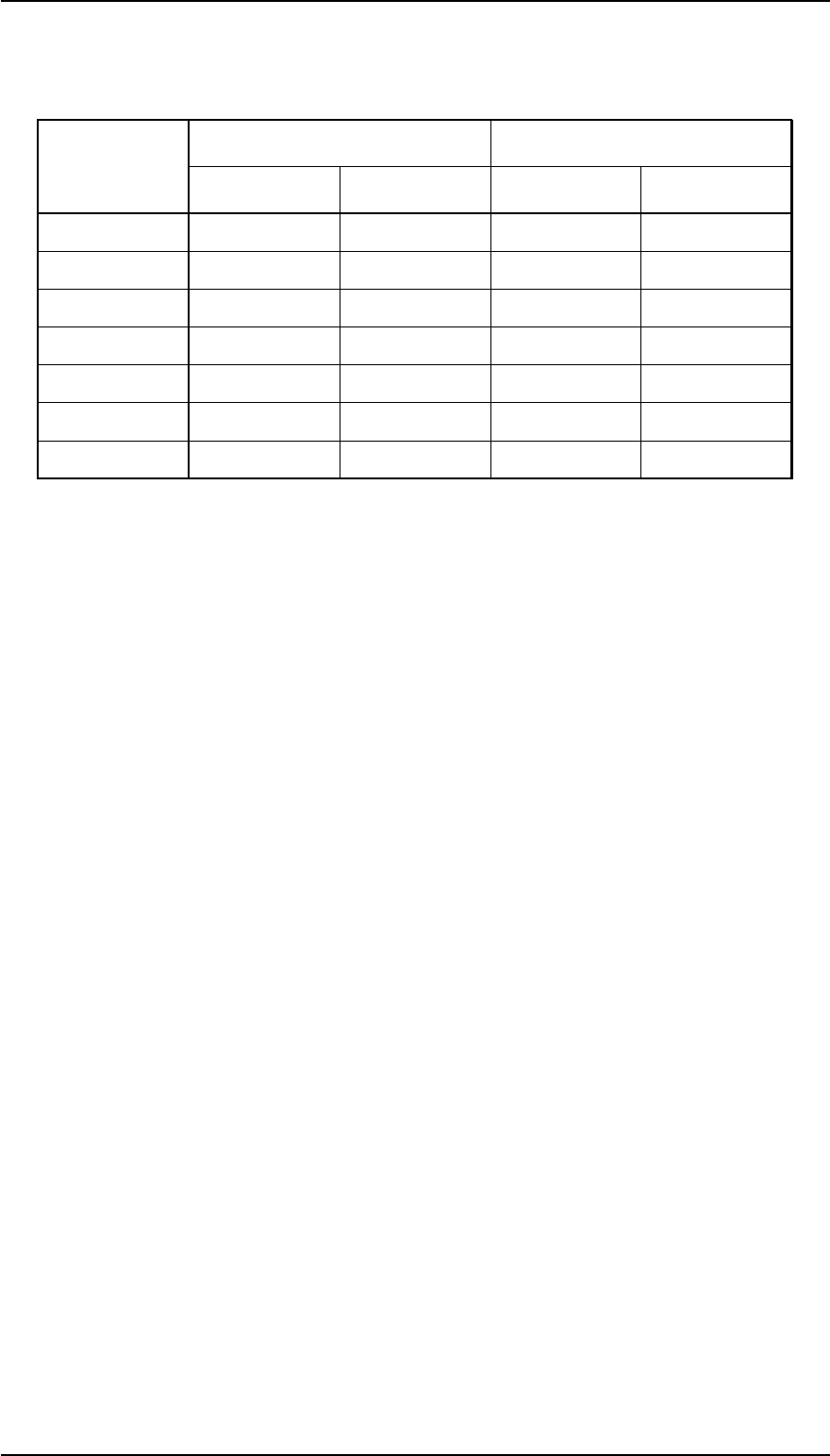

Table 1-7 Paper Thickness Lever Positions

Lever Position

Paper Thickness ( inches) Paper Thickness (mm)

Minimum Maximum Minimum Maximum

0 0.0024 0.0043 0.06 0.11

1 0.0043 0.0067 0.11 0.17

2 0.0070 0.0075 0.18 0.19

3 0.0079 0.0098 0.20 0.25

4 0.0098 0.0122 0.25 0.31

5 0.0126 0.0150 0.32 0.38

6 0.0153 0.0181 0.39 0.46

———————— Precautions for Handling Paper ————————

1. Friction feed

Set the release lever to the FRICTION position and install the paper eject assembly

Load paper from the front or top entrance. Do

not use continuous paper. Do not

perform any reverse paper feeds within the top 8.5 mm (0.33 inch) and bottom 22 mm

(0.87 inch) area.

Do not perform reverse feeds greater than 1/6 inch after the paper end has been detected.

Use the paper-tension unit.

Insert the multipart cut sheet forms only from the front.

2. Push tractor feed

Set the release lever to the REAR PUSH/FRONT PUSH position and install the paper eject

assembly.

Load paper from the rear or front entrance.

Release the friction feed mechanism.

Multipart paper must be carbonless. Use

the paper-tension unit. Do not

perform reverse feeds greater than 1/6 inch. Do not

perform reverse feeds after the paper end has been detected, because accuracy of

paper feeding cannot be assured.

3. Pull tractor feed

Set the release lever to the PULL position.

Load paper from the front, rear, or bottom entrance. (The

front or bottom entrance is recommended for thick paper or labels.)

Remove the paper eject assembly and attach the pull tractor unit.

Insert paper from either from the front or bottom.

Multipart paper must be carbonless. Do

not perform reverse feeds.

FX-2170 Service Manual Product Description

Rev.A 1-7