CTI 2572 Installation and Operation Guide

133

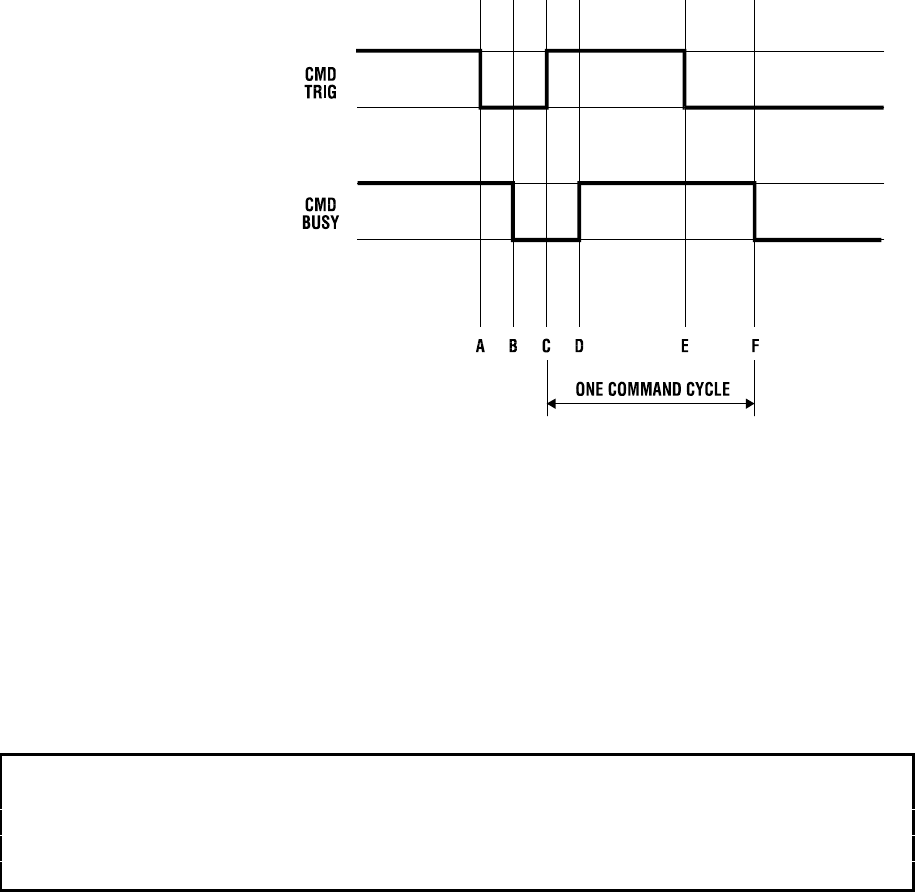

Command Timing Diagrams

Coupled Mode Timing (CMD Mode = 1)

Coupled Mode should be selected when you want to ensure that the module will execute a command

only once per trigger. In Coupled Mode the PLC and the module use the CMD TRIG (Command

Trigger) and the CMD BUSY (Command Busy) bits in a "handshaking" sequence. The following

figure illustrates the timing relationships between CMD TRIG and CMD BUSY for a Coupled Mode

command.

The PLC has cleared CMD

TRIG (Time A) and the

module has cleared CMD

BUSY (Time B) indicating

that the processing of the

previous command is

complete.

At Time C, the PLC asserts

CMD TRIG to initiate a

command. When the module

recognizes that CMD TRIG is

high, it asserts CMD BUSY

(Time D) and samples the

CMD MODE bit to determine

the command mode. It then

retrieves the command block

and starts processing the

command. Any time after the

PLC sees CMD BUSY go

high, it may lower CMD TRIG (Time E).

Once the module completes processing the command, it samples CMD TRIG. If CMD TRIG is off,

the Module will lower CMD BUSY (Time F) and wait for the next trigger. If CMD TRIG is on, the

module will hold busy high and wait until CMD TRIG is turned off. Time F will be delayed as

required until CMD TRIG is off. At time F (equivalent to time B), both CMD TRIG and CMD

BUSY are low and a new cycle can begin whenever the PLC asserts CMD TRIG.

NOTE:

The Command Block is subject to access and change by the module anytime after CMD TRIG is

asserted (time C) until CMD BUSY is cleared (time F). Thus, the Command Block should not be

changed by the PLC at any time between time C and F.

Figure 23. Coupled Mode Timing