176

Print Media Guidelines

• Before loading the paper, identify the recommended print side of the paper. This information is usually indicated

on the paper package.

• Do not use paper that you have cut or trimmed.

• Do not mix print media sizes, weights, or types in the same source. This may result in a paper jam.

• Do not remove the tray while printing is in progress.

• Ensure that the paper is properly loaded in the tray.

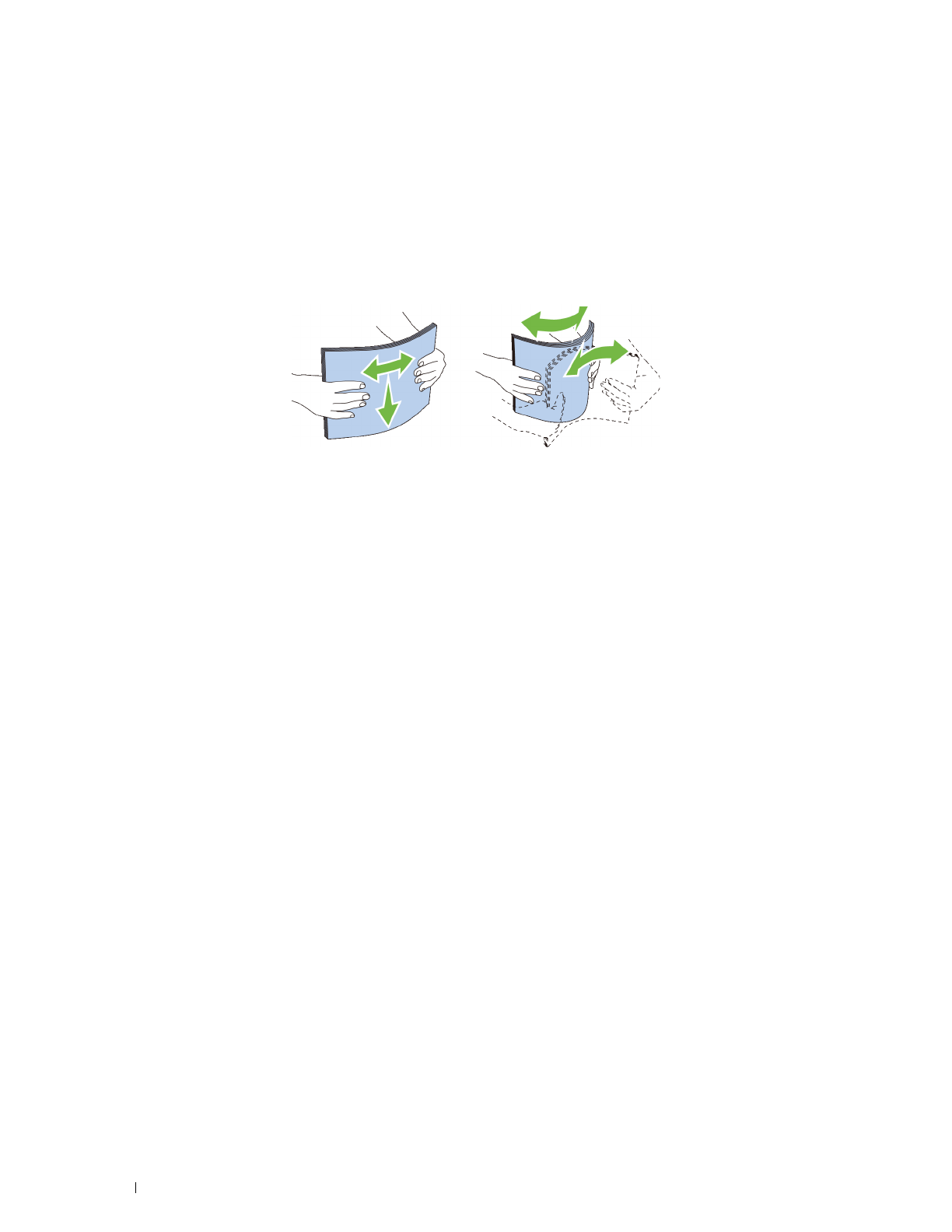

• Flex the paper back and forth, and then fan them. Straighten the edges of the stack on a level surface.

Selecting Pre-Printed Media and Letterheads

When selecting pre-printed and letterhead paper for the printer:

• Use grain long paper for best results.

• Use only forms and letterheads printed using an offset lithographic or engraved printing process.

• Select paper that absorb ink, but does not bleed.

• Avoid paper with rough or heavily textured surfaces.

• Use paper printed with heat-resistant inks designed for use in xerographic copying machines. The ink must

withstand temperatures of 225 °C (437 °F) without melting or releasing hazardous emissions.

• Use inks that are not affected by the resin in the toner or the silicone in the fusing unit. Inks that are oxidation-set

or oil-based should meet these requirements; latex inks might not. If you are in doubt, contact your paper supplier.

Selecting Pre-Punched Paper

When selecting pre-punched paper for the printer:

• Test paper from several manufacturers before ordering and using large quantities of pre-punched paper.

• Paper should be punched at the paper manufacturer and not drilled into paper already packaged in a ream. Drilled

paper can cause jams when multiple sheets feed through the printer. This may result in a paper jam.

• Pre-punched paper can include more paper dust than standard paper. Your printer may require more frequent

cleaning and feed reliability may not be as good as standard paper.

• Weight guidelines for pre-punched paper are the same as non-punched paper.