Chapter 3 Connections and Wiring|ASDA-AB Series

Revision January 2009 3-19

NOTE

1) PINS 3 & 2 can either be TSPD or HOME dependent upon control mode selected.

2) PINS 1 & 26 are different depending on control mode either BRKR or TPOS.

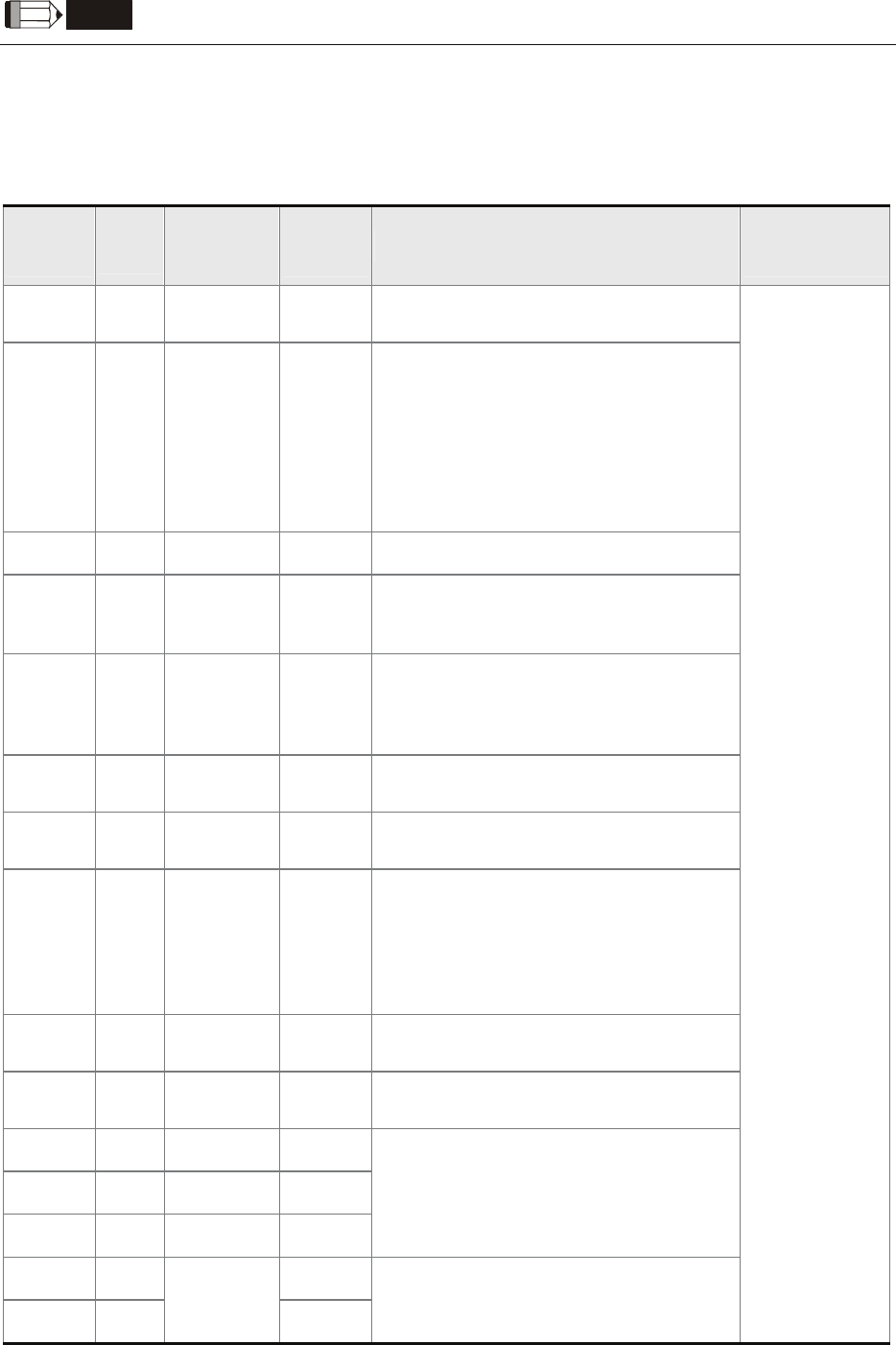

Table 3.C DI Signals

DI

Signal

DI

Code

Assigned

Control

Mode

Pin No.

(Default)

Details

(*2)

Wiring Diagram

(Refer to 3-3-3)

SON 01 ALL 9

Servo On. Switch servo to "Servo Ready".

Check parameter P2-51.

ARST 02 ALL 33

A number of Faults (Alarms) can be

cleared by activating ARST. Please see

table 10-3 for applicable faults that can be

cleared with the ARST command.

However, please investigate Fault or

Alarm if it does not clear or the fault

description warrants closer inspection of

the drive system.

GAINUP 03 ALL - Gain switching

CCLR 04 Pt 10

When CCLR is activated the setting is

parameter P2-50 Pulse Clear Mode is

executed.

ZCLAMP 05 ALL -

When this signal is On and the motor

speed value is lower than the setting value

of P1-38, it is used to lock the motor in the

instant position while ZCLAMP is On.

CMDINV 06 Pr, T, S -

When this signal is On, the motor is in

reverse rotation.

HOLD 07

Not

assigned

Internal position control command pause

CTRG 08

Pr,

Pr-S, Pr-T

10

When the drive is in Pr mode and CTRG is

activated, the drive will command the

motor to move the stored position which

correspond the POS 0, POS 1, POS 2

settings. Activation is triggered on the

rising edge of the pulse.

TRQLM 09 S, Sz 10

ON indicates the torque limit command is

valid.

SPDLM 10 T, Tz 10

ON indicates the speed limit command is

valid.

POS0 11 Pr 34

POS1 12 Pr-S, Pr-T 8

POS2 13 - -

When the Pr Control Mode is selected the

8 stored positions are programmed via a

combination of the POS 0, POS 1, and

POS 2 commands. See table 3.D.

SPD0 14 34

SPD1 15

S, Sz, Pt-S,

Pr-S, S-T

8

Select the source of speed command:

See table 3.E.

C9/C10