ENWW Corona unit section 61

MFP unit explanation

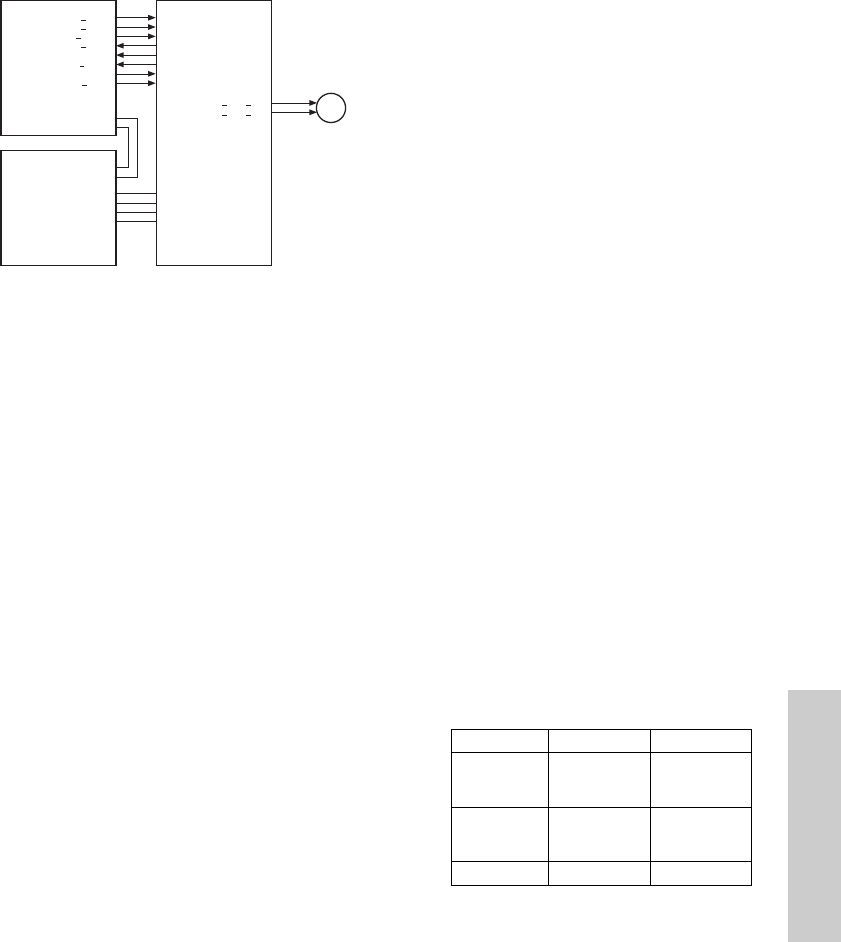

M10 (transfer/separation

cleaning) control

M10 (transfer/separation cleaning) is a DC

motor powered by 24 VDC and is controlled

by PRCB (printer control board) via ADUDB

(ADU drive board). Between PRCB and

ADUDB, signals are exchanged using serial

data.

1 Operation

a Purpose of driving

M10 (transfer/separation cleaning) used

to drive the transfer/separation wire

cleaning pads.

b Operation timing

The transfer/separation wires are

cleaned when SW2 (sub power) is

turned on or when the fuser

temperature is lower than 50° C.

It is also carried out after the specified

copy count is reached.

*Changeable with the 25-mode DIP SW

c Cleaning operation

Normally, the transfer/separation wire

cleaning pads are on the front side of

the machine. They move back and forth

to clean the transfer and separation

wires. The movement direction is

changed by changing the rotational

direction of M10 (transfer/separation

cleaning).

The rotational direction of M10 and the

position of the cleaner are detected by

monitoring the current value of M10 with

PRCB (printer control board).

2 Signals

a Input signals

1 IO_URXD (ADUDB to PRCB)

Serial data used to report the ADUDB

(ADU drive board) operation state to

PRCB (printer control board)

2 REQ1 (ADUDB to PRCB)

This signal indicates that sending

data from ADUDB (ADU drive board)

to PRCB (printer control board) is

requested.

When ADUDB receives ACK1 and

can send data, this signal stands at

the [L] level.

3 IO_UCLK (ADUDB to PRCB)

Clock signal for IO_URXD signal

b Output signals

1 SEP_CLM_M A, B (ADUDB to M10)

M10 (transfer/separation cleaning)

drive control signal

The drive direction of M10

(transfer/separation cleaning) drive

control signal

The drive direction of M10 is

controlled by switching between the

drive current directions of two signals.

ADUDB

SEP CLM M A

SEP CLM M B

PRCB

IO DTXD

IO DCLK

ADU LATCH

IO UCLK

REQ1

IO URXD

ACK1

ERR OUT1

DCPS

24V1

5V2

S.GND

P.GND

5V2

S.GND

M10

Status SEP_CLM_MA SEP_CLM_MB

Forward

stroke of

cleaning

HL

Backward

stroke of

cleaning

LH

Stop L L