177

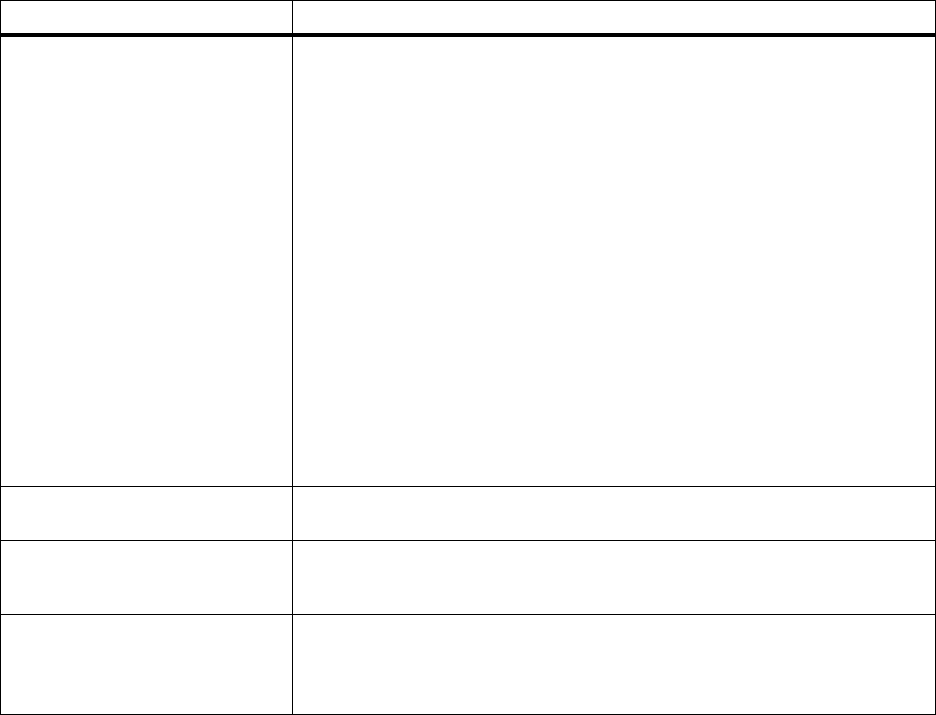

Printing Problems

Print material misfeeds or multiple

feeds occur.

• Make sure the print material you are using meets the specifications for your

printer. See “Print Material Guidelines” on page 118 for more information.

• Flex print material before loading it in any of the paper sources.

• Make sure the print material is loaded correctly.

• Make sure the paper width and length guides on the paper sources are

adjusted correctly and are not too tight.

• Do not overfill the paper sources.

• Do not force print material into the multipurpose feeder when you load it;

otherwise, it may skew or buckle.

• Remove any curled print material from paper sources.

• If there is a recommended print side for the print material, load the print

material as described in “Print Material Guidelines” on page 118.

• Load less print material in the input sources.

• Turn the print material over or around and try printing again to see if feeding

improves.

• Do not mix print material types.

• Do not mix reams of print material.

• Remove the top and bottom sheets of a ream before loading the print

material.

• Load an input source only when it is empty.

You get unexpected page breaks. Check the

Print Timeout settingintheSETUP MENU. Increase the setting. See

Print Timeout on page 74 for more information.

Job prints from the wrong input

source or on the wrong print

material.

Check the

PAPER TYPE setting in the PAPER MENU on the operator panel and

in the printer driver. See

PAPER TYPE on page 47 for more information.

Print material does not stack

neatly in an output bin.

• Turn the print material stack over in the tray or multipurpose feeder.

• If the print material is exiting to the standard output bin, make sure the paper

bail is installed correctly. See “Installing the Paper Bail” on page 11 for more

information.

Problem (continued) Action (continued)