RMAN-QLS-002 rev. A Repair Procedures • 2-48 •

media guide pLate aSSembLy, QL220/220 pLuS

Kit p/n Description Type

AN16972-007 KIT REPAIR QL2 MEDIA GUIDE PLA Rack and Pinion

AN16972-023 KIT REPAIR QL2 MEDIA GUIDE ASSy w/ MW Rack and Pinion

RK18467-001 KIT RPR QL2 MEDIA GUIDE W/BELT Belt/ Linered Medai

RK18467-002 KIT QL2 MEDIA GUIDE LNL W/BELT Belt/Linerless Media

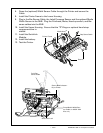

1. Turn the printer off and remove the battery pack.

2. Remove the Upper Housing.

3. Remove the Lower Housing.

4. Unplug the following cables from the MLB: J5 (Label Presence Sensor), J10

(Gap Sensor). If unit has the Media Width Sensor, unplug J11 from the bottom

of the board.

5. Unplug the keypad or LCD connectors from the MLB.

6. Remove the 2 screws retaining the printer frame to the chassis. Carefully re-

move the MLB and Printer Frame from the chassis, avoiding cable strain.

Screw, #4-40 x 3/16” Skt Hd. (2)

Torque = 5 in/lbs

Dress Peel Sensor and Media Width Sensor

cable from Media Plate Assembly through

slot in Printer Frame.

Printer Frame

Press Latch Lock here to

test locking feature.

Slide Rack Lock this way to allow Media Plate

Assembly to locate.

Media Supports

You must use an ESD strap and work at a properly grounded workstation (antistatic mat or tray).

All electronic components must be placed on an ESD protective tray. If stored, any elec-

tronic components must be placed in antistatic bags.