RMAN-QLS-002 rev. A Repair Procedures • 2-50 •

Kit p/n Description

RK16823-043 KIT RPR QL320 MEDIA GUIDE/MW

RK18460-1 KIT RPR QL3 MEDIA GUIDE W/BELT

RK18461-1 KIT QL3 MEDIA GUIDE LNL W/BELT

RK18462-1 KIT QL3 MEDIA GUIDE MW W/BELT

RK18463-1 KIT QL3 MEDIA GUIDE LNL MWBELT

Tools needed

#1 Phillips Head Screwdriver.

3/32” hex driver

Removing the Media Assembly

1. Turn the printer off and remove the battery pack.

2. Remove the QuickLink Module and retain the parts.

3. Remove the Upper Housing and retain the parts.

4. Unplug the following cables from the MLB: J5 (Label Presence Sensor), J10

(Gap Sensor). If unit has the Media Width Sensor option, unplug J11 from the

bottom of the board. Unplug the Printhead, Motor, Head-up switch, and Bar

sense cables from the MLB.

5. Remove the Printer Frame and Media Cover and retain the parts.

6. Remove the Gap Sensor Cable Ground from the Printhead.

7. Remove and retain the Screws securing the Media Assembly to the Printer.

8. If the Printer is equipped with the Media Width Sensor option, pull the sensor

cable free of the Printer Frame.

9. Remove the Media Assembly. Rock the Media Assembly forward and then lift

it away from the Printer Frame. Keep the Gap Sensor Cable with the Media As-

sembly.

Installing the Media Assembly

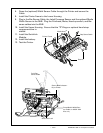

1. All Repair Kits: Assemble the Gap Sensor

Insert the sensor on the Gap Sensor Cable into the Plate, Edge Guide as shown.

The large hole in the cable will t over the mounting boss on the Plate, Edge

guide. Dress the grounding strap portion of the cable assembly away from the

Plate Edge Guide as shown.

2. For RK16823-043 Only

Install the Gear, 32P, 14T on the Edge Guide Assembly. Squeeze the two media

Supports together as far as they will travel. Slide the Gear 32P, 14T over the

shaft on the Edge Guide Sub-Assembly, engaging the teeth on the two racks

with the teeth on the gear.

3. All Repair Kits: Install the Media Assembly

media guide aSSembLy, QL320/320 pLuS

You must use an ESD strap and work at a properly grounded workstation (antistatic mat or tray).

All electronic components must be placed on an ESD protective tray. If stored, any elec-

tronic components must be placed in antistatic bags.