ADJUSTMENT

4.1.6 Platen Angle Adjustment

This section describes the platen angle adjustment. The platen must be at a right angle to the carriage

assembly. This adjustment is required when the platen is removed or replaced or when the two hexagonal

screws securing the platen to both side frames are loosened. Do not remove the printer mechanism from the

lower case. (If remove the printer mechanism from the lower case, the adjust value will be out of order when

you reassemble the pnnter mechanism to the lower case.) Also, it is necessary to remove the tension roller

shaft be fore performing this adjustment. (Refer to Section 3.2.6.7)

The parallelism is @sted so that the difference behveen the distances (from the rear carriage gui&

shaft to the p/a&n measured at the two positions shown in Figure 4-7) is less than & 0.015 mm. Sines

this value is extremely smaf/, you must use the hvo dial gauges, dial gauge base, and dial gauge

master supplied by EPSON. Do not a@ust the parallelism using any other method.

0 Dialgauge #F610 (Part No. BlOf9466)

0 Dialgaugebase#Ffill (PartNo. 81019467)

0 Dial gauge master #F612 (Part No. 81019468).

Step 1: Perform the carriage guide shaft parallelism adjustment. (Refer to section 4.1.5) After the adjustment

is finished, leave the dial gage unit on the carriage.

Step 2: Remove the pull tractor sensor.(Refer to S&ion 3.2.6.10.)

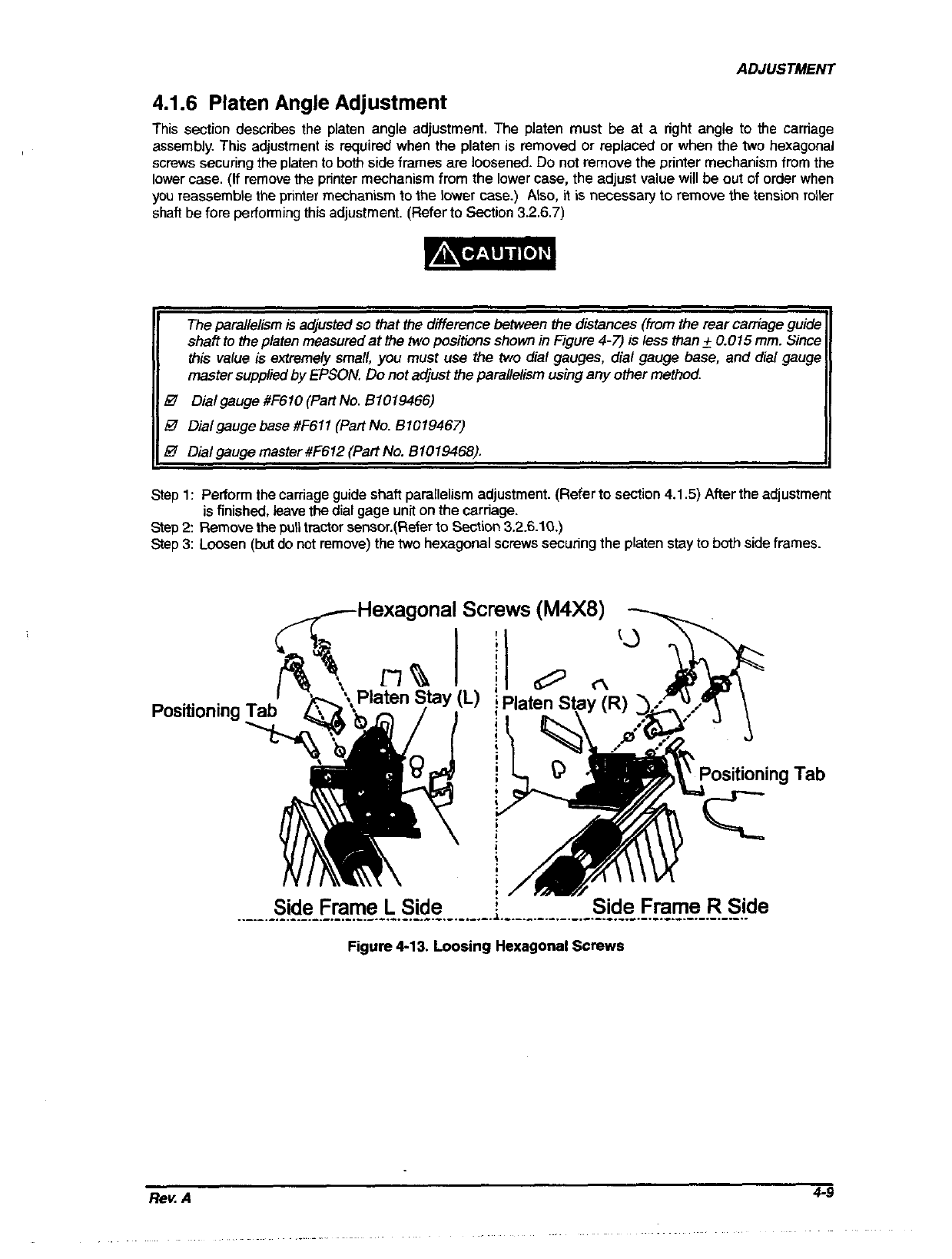

Step 3: Loosen (but do not remove) the two hexagonal screws securing the platen stay to both side frames.

rews (M4X8)

ing Tab

Side Frame L Side

i Side Frame R Side

.._._._._._._._._._._._._._._._._._.~.~._._._.~.~.~._._.~.~._._.~~.~._.~~.~.~.~.~~.~.~.~..

Figure 4-13. Loosing Hexagonal Screws