OPERATING PRINCIPLES

2.1.2 Carriage Mechanism

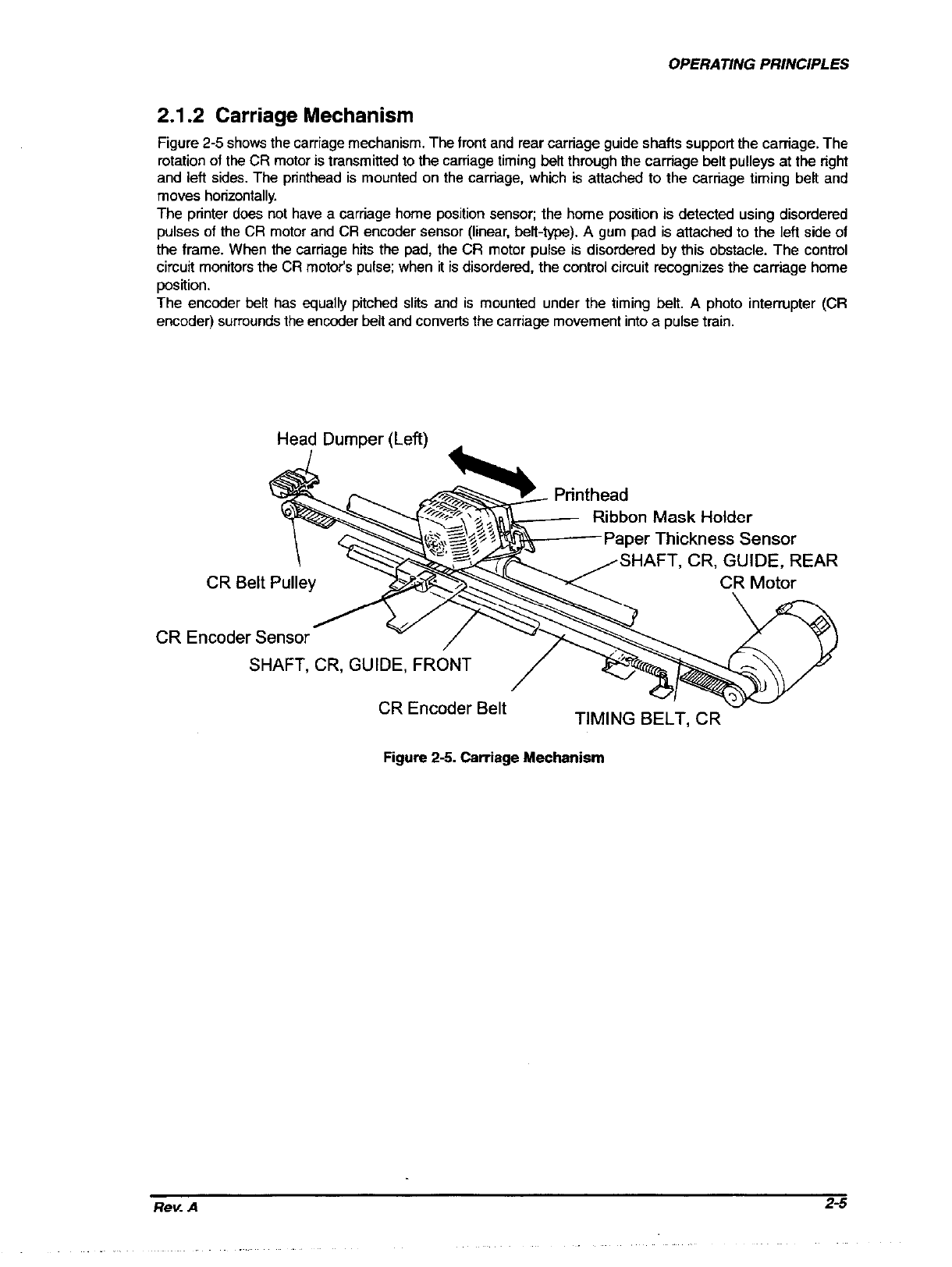

Figure 2-5 shows the carriage mechanism. The front and rear carriage guide shafts support the carriage. The

rotation of the CR motor is transmitted to the carriage timing belt through the carriage belt pulleys at the right

and left sides. The printhead is mounted on the carriage, which is attached to the carriage timing bek and

moves horizontally.

The printer does not have a carriage home position sensor; the home position is detected using disordered

pulses of the CR motor and CR encoder sensor (linear, bek-type). A gum pad is attached to the left side of

the frame. When the carriage hits the pad, the CR motor pulse is disordered by this obstacle. The control

circuit monitors the CR motor’s pulse; when it is disordered, the control circuit recognizes the carriage home

position.

The encoder belt has equally pitched slits and is mounted under the timing belt. A photo interrupter (CR

encoder) surrounds the encoder belt and converts the carriage movement into a pulse train.

Head Dumper (Left) _

Encoder Sensor

4r aelr

!_ Printhead

:’

\‘A., R

Ribbon Mask Holder

Z-Paper Thickness Sensor

/SHAFT, CR, GUIDE, REAR

- TIMING BELT, CR

Figure 2-5. Carriage Mechanism

Rev. A

2-5