DFX-8500

4.1.7 Platen Gap Motor Value Adjustment

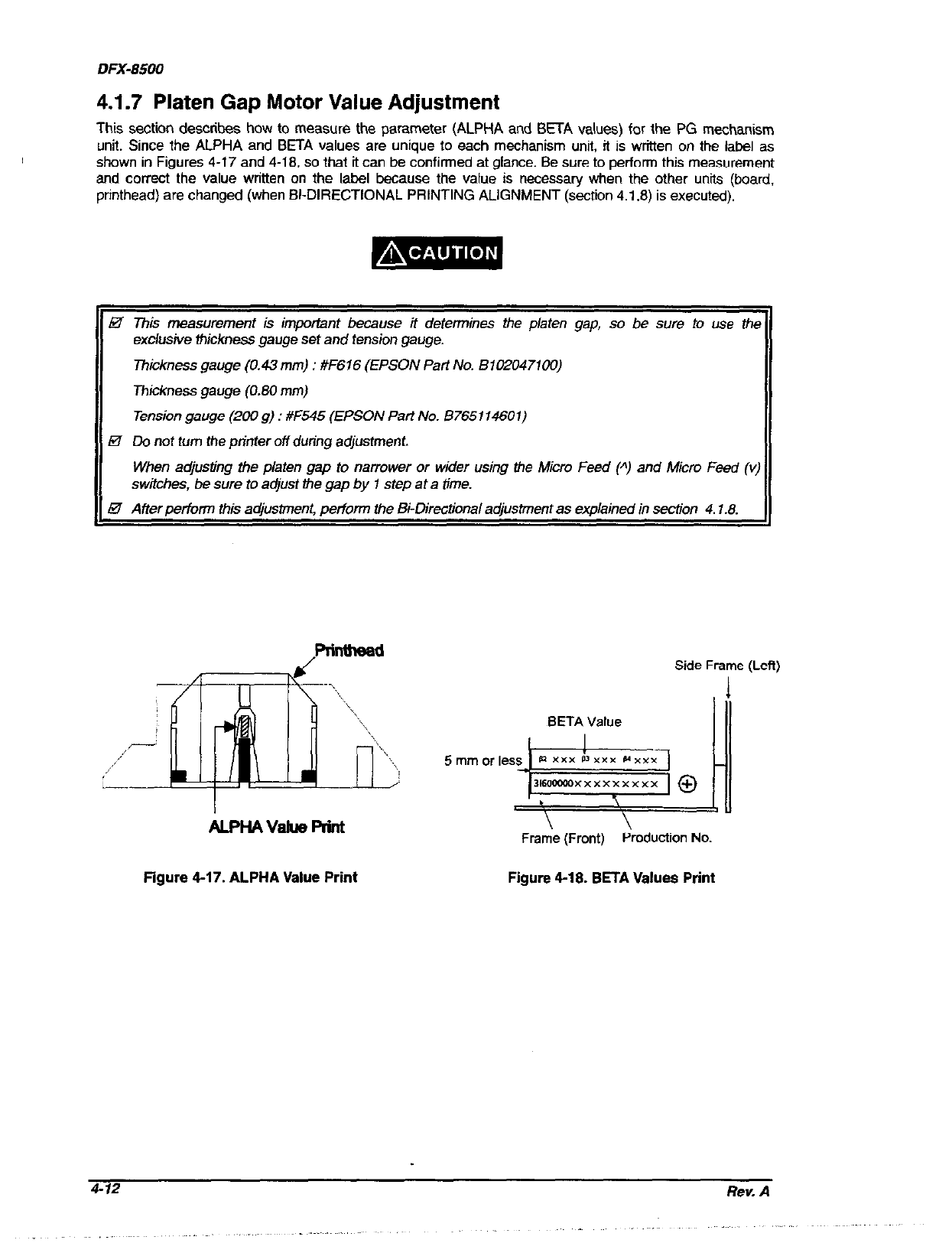

This se&in describes how to measure the parameter (ALPHA and BETA values) for the PG mechanism

unit. Since the ALPHA and BETA values are unique to each mechanism unit, it is written on the label as

shown in Figures 4-17 and 4-10, so that it can be confirmed at glance. Be sure to perform this measurement

and correct the value written on the label because the value is necessary when the other units (board,

printhead) are changed (when BI-DIRECTIONAL PRINTING ALIGNMENT (section 4.1.8) is executed).

@ This measurement is important because it determines the platen gap, so be sure to use th

exclusive !hicknees gauge set and fension gauge.

Thickness gauge (0.43 mm) : #F616 (EPSON Part No. SlOZO47lCO)

Thickness gauge (0.80 mm)

Tension gauge (200 g) : #F545 (EPSON Part No. B765114601)

9

Do not turn the printer off during adjustment.

When @Ming the platen gap to narrower or wider using the Micro Feed (A) and Micro Feed (c

switches, be sure to adjust the gap by 1 step at a time.

Y After perfcxm this a@ustment, pertom the BcDirectional a$ustment es explained in section 4.1.8.

Rinthead

Side Frame (Left)

BETA Value

ALPHAVdWPliIlt

Frame (Front) Production No.

Figure 4-17. ALPHA Value Print Figure 4-18. BETA Values Print

Rev. A